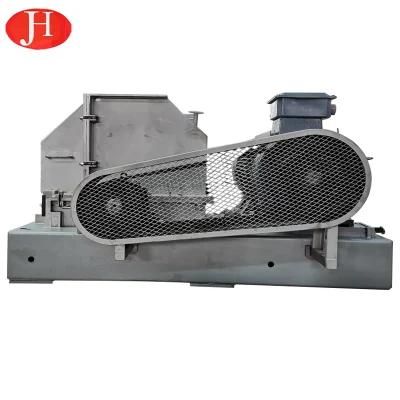

Potato Starch Grinding Machine Stainless Steel Rasper Fresh Potato Mill Grinder Equipment

Zhengzhou Jinghua Industry Co., Ltd.- Type:Flour Mill

- Application:Flour, Starch, Potato

- Voltage:220V

- Appearance:Vertical

- Press Materials:Potato

- Press Series:Potato Grinder Machine

Base Info

- Model NO.:DCM8435 DCM8450 DCM1070 DCM8465

- Condition:New

- Customized:Customized

- Product Name:Potato Grinder Machine

- Advantage:Large Capacity

- Service:Overseas Installation

- Useful Life:20 Years

- Keywords:Potato Starch Grinder Machine

- Capacity:5-30 T,H

- Energy:Electric

- Weight:1200 Kg

- Material:Stainless Steel

- Warranty:1 Year

- Dimension:3100*800*650 mm

- Power:250 Kw

- Main Shaft Rotating Speed:2100 R,Min

- Drum Diameter:840 mm

- Transport Package:Wooden Case

- Specification:stainless steel

- Trademark:JINGHUA

- Origin:Zhengzhou City, China

- Production Capacity:10 Sets,Month

Description

Basic Info.

Model NO. DCM8435 DCM8450 DCM1070 DCM8465 Condition New Customized Customized Product Name Potato Grinder Machine Advantage Large Capacity Service Overseas Installation Useful Life 20 Years Keywords Potato Starch Grinder Machine Capacity 5-30 T/H Energy Electric Weight 1200 Kg Material Stainless Steel Warranty 1 Year Dimension 3100*800*650 mm Power 250 Kw Main Shaft Rotating Speed 2100 R/Min Drum Diameter 840 mm Transport Package Wooden Case Specification stainless steel Trademark JINGHUA Origin Zhengzhou City, China Production Capacity 10 Sets/MonthProduct Description

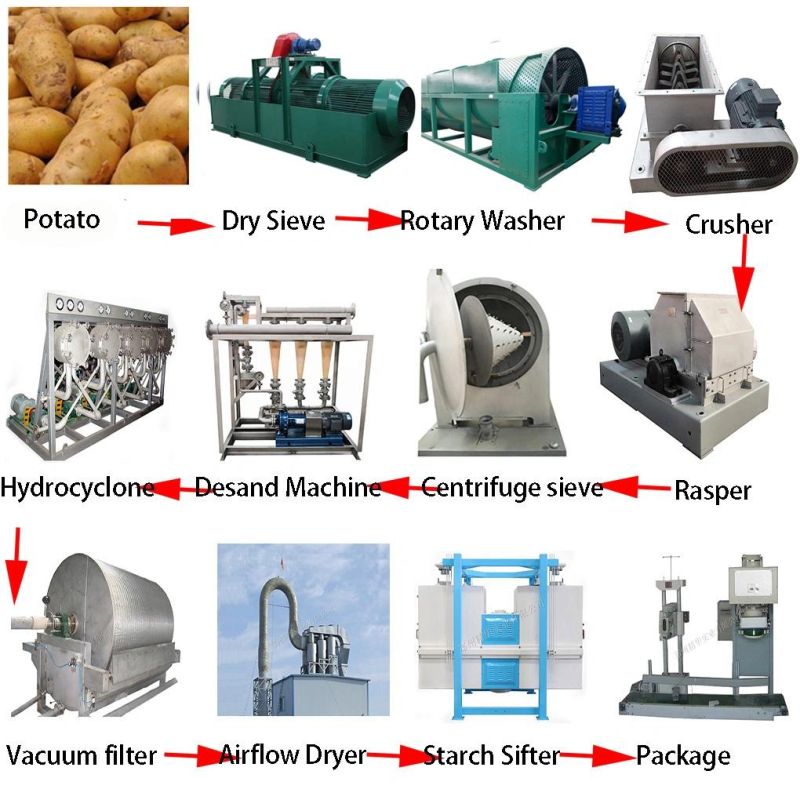

potato starch grinding machine stainless steel rasper fresh potato mill grinder equipment1.Introduction of potato starch grinder machine

Potato starch is mainly stored in the fleshy part of the root, the raw material particles are relatively large, the internal organization is not easy to destroy, the use of repeated file grinding, fully destroy the potato block structure, can make the small starch particles can be successfully free from the root, improve the extraction rate of starch.

Key Technology & Innovation Potions

1. All parts in contact with raw material are made of food-grade stainless steel, which protects materials from outer pollution.

2. High rotating speed, high line speed, excellent rasping performance, uniform particle, and high starch ionization rate.

3. Rotor is calibrated with international advanced dynamic-balance instrument, meeting G1 standard.

4. Components(bearings for example) are imported from Europe with longer service life

5. Unique sieve-tension gear makes disassembly easy.

Main technical parameters

| Model | DCM8435 | DCM8450 | DCM8465 | DCM1070 |

| Main shaft rotating speed(r/min) | 2100 | 2100 | 2100 | 1470 |

| Drum diameter (mm) | Φ840 | Φ840 | Φ840 | Φ1100 |

| Drum width (mm) | 350 | 500 | 650 | 700 |

| Power (Kw) | 110 | 160 | 200 | 250 |

| Capacity (t/h) | 20-23 | 30-33 | 35-40 | 40-45 |

| Dimension(mm) | 2170x1260x1220 | 2170x1385x1250 | 2170x1650x1380 | 3000x1590x1500 |

Structure introduction

Complete machine consists of rotor, rasping blade, engine base, upper cover, side cover, bearing base, gearing, motor, etc.

1. Engine base props up all components, which rotor and bearings are all fixed on.

2. Rotor is made of special stainless steel, uniform grooves on the surface to install saw blade.

3. Saw blade is comprised of 2 stainless-steel layer with locating pin and a saw blade.

4. Combined rasping blade are equipped on both side of rotor, which could achieve rotor two-way rotating and crests higher crushing rate.

5. A sieve is equipped between rasping blades, which is tensioned by two sets tensioning instruments.

The working principle of rasper

The material enters into the body of the file mill shell through the upper entrance, and is broken by the impact, shear and grinding effect of the saw blade moving at high speed. The lower part of the rotor is equipped with a screen screen. The material smaller than the size of the screen hole is discharged through the screen plate, and the particles larger than the size of the screen hole are blocked and remain on the screen plate to continue to be hit and grinder by the saw blade.

Real application case

2.Company InformationZhengzhou Jinghua Industry Co.,Ltd. is a professional starch engineering corporation in China. Depending on the unique advantage and strong strength of Henan University of Technology, Jinghua combines scientific research, industry and trade as a whole, which mainly engaged in the working of factory layout, technology design,complete equipment manufacturing and commissioning, new product developing etc. to all kinds starch processing. Has two modern large factory, engineering and technical personnel more than 30 people, can provide installation services overseas. Our company has undertaken national and provincial scientific research projects.,with more than 30 invention patents, various honor certificate more than 20.The chairman of the board is professor wang yanbo, who is mainly engaged in theoretical research on the transformation and utilization of grain resources, teaching, scientific research and engineering design of starch and its deep processing direction, and research and development of modern equipment. He has published 7 scientific works, 6 national standards and 30 academic papers.

2.Company InformationZhengzhou Jinghua Industry Co.,Ltd. is a professional starch engineering corporation in China. Depending on the unique advantage and strong strength of Henan University of Technology, Jinghua combines scientific research, industry and trade as a whole, which mainly engaged in the working of factory layout, technology design,complete equipment manufacturing and commissioning, new product developing etc. to all kinds starch processing. Has two modern large factory, engineering and technical personnel more than 30 people, can provide installation services overseas. Our company has undertaken national and provincial scientific research projects.,with more than 30 invention patents, various honor certificate more than 20.The chairman of the board is professor wang yanbo, who is mainly engaged in theoretical research on the transformation and utilization of grain resources, teaching, scientific research and engineering design of starch and its deep processing direction, and research and development of modern equipment. He has published 7 scientific works, 6 national standards and 30 academic papers. Our Factory

Our Workshop

Our Workshop

Our Certificate

3.Our ServicePre-sale service

1.Accept customer consultation and customize products according to customer requirements.

2.Provide customers with product process, equipment parameters and processes, and train personnel according to customer requirements.

Sale service

1.The company sent technical personnel to the scene of the on-the -spot guidance equipment installation,debugging and training operators.

2.If there is any problem during the installation, please contact the responsible person in time. We will solve the problem in time to ensure the installation progress.

After-sale service

1.Provide telephone and video support. If the customer has any problems or abnormal devices in use, you can contact us by phone. We will help the customer solve the problems by phone or video.

2.If the phone or video doesn't work, the company will send technicians to the scene to fix the problem.

3.Products purchased in our company, we provide one-year warranty and lifelong maintenance service.

4.Packing & Shipping

Packing & Shipping: Customize the wooden case according to the size of the product.

Delivery: 14 days after receiving pre-payment (on time according to contract strictly).

5.FAQQ1: Is your company a factory or trading company?

A: Our company is a factory in Henan Province ,with export license and we have done export business over 20 years professionally.

Q2.What is your main business?

A: Zhengzhou Jinghua is devoted to starch processing machine. The machine of starch processing line , such as : cassava starch line , cassava flour line , potato starch line , sweet potato line , wheat starch ,sago line and garri line

Q3. Can you customize the products according to our requirements?

A: Yes, we have a professional technical department that can customize the products according to your requirements

Q4: Are your products can be assured ?

A: Our machines are all passed ISO9001:2001 and have CE certificate by SGS, TUV.

Q5: If we show you our layout of factory, can you help us to design the whole process line?

A : Yes, our experienced engineers and technical employees can help you to arrange the layout and installation of whole process line based on your real situation;

Q6: If we have samples of new products, can you help us to analysis and design the machine?

A: Yes, Our technical department can help you to analysis, design and test the new products you offered.

Zhengzhou Jinghua Industry Co.,Ltd.

Add:Guanggu Road, Xingyang City,Henan Province,China