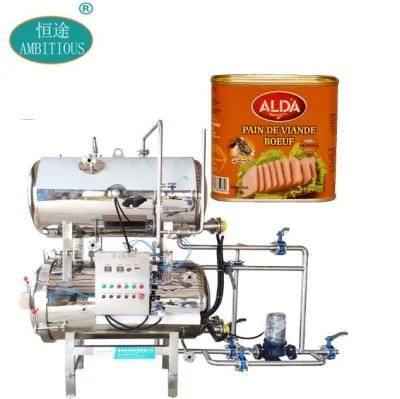

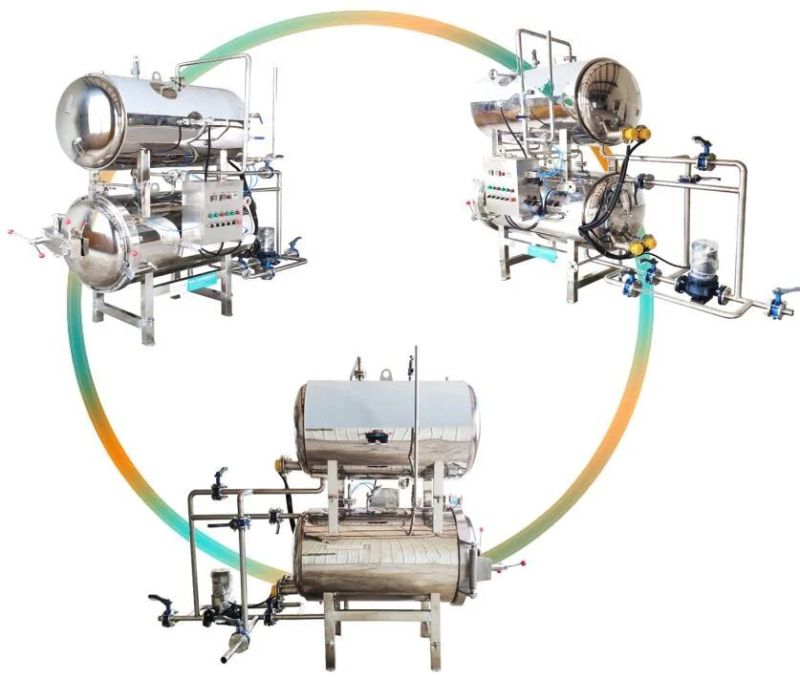

Sterilizer Mini Food Retort Machine Autoclave Sterilizer Steam Sterilizing Kettle

Zhucheng Tianshun Machinery Co., Ltd.- After-sales Service:Door to Door or Video

- Warranty:1 Year

- Usage:Meat

- Power Source:Electric

- Timing Device:With Timing Device

- Type:Mixer

Base Info

- Model NO.:TS

- Voltage:380V

- Customized:Customized

- Material:304 Stainless Steel or According to Customer Requi

- Heating Method:Steam Heating

- Transport Package:According to Customer Requirement

- Specification:360

- Trademark:Ambitious

- Origin:China

- HS Code:8438600000

- Production Capacity:20pieces,Year

Description

Basic Info.

Model NO. TS Voltage 380V Customized Customized Material 304 Stainless Steel or According to Customer Requi Heating Method Steam Heating Transport Package According to Customer Requirement Specification 360 Trademark Ambitious Origin China HS Code 8438600000 Production Capacity 20pieces/YearProduct Description

Sterilizing kettle 1.-Sterilizing Kettle

1.-Sterilizing Kettle Water steam is used to raise the pressure and temperature in the pot, thus killing the miscellaneous bacteria

and spores in the contents of the pot, to achieve the purpose of sterilization.The use of four heating, four cooling, not only to make the material sterilization effect is better, but also greatly

reduce the sterilization time, improve production efficiency.Visualization of operating procedures, support manual / automatic mode switch.

2.-Sterilizing Kettle Applications

2.-Sterilizing Kettle ApplicationsPlastic containers: PP bottle, HDPE bottle,

Soft bag packaging: aluminum foil bag, high temperature transparent bag, high temperature vacuum bag and other

packaging food, beverage can storage materials cooking sterilization.

3.-Technical parameters

3.-Technical parameters| Item | Content |

| Inner diameter/tube length/volume | 1200mm/3600 /4.6 |

| Design pressure | 0.35 Mpa |

| Work pressure | 0.3 Mpa |

| Test pressure | 0.44Mpa |

| Maximum working temperature | 145ºC |

| Equipped with boiler model / minimum pressure | 1.5T/6kg |

| Total installed power | 15KW |

| Voltage | 380V |

| Sterilization tray size | According to customer requirements |

| Pot body material | 06Cr19Ni10 |

| Pot wall thickness | 6mm |

| Area | 5800*4000*3200(Length*Width*Height) |

| Water quality requirements | Tap water, the chloride ion content in the water is not higher than 25mg/L |

| Steam | 360kg |

| Tap water | 5600L(Can be recycled) |

| Capacity | Each can of processed food is approximately: 600kg (take leisure products as an example) |

4..-Company and Workshop

Zhucheng Tianshun Machinery Co.,Ltd. is a modern food equipment and machinery manufacturing enterprise

which integrating R & D, production, sales and after-sales services.

Mainly manufactures food frying machine,washing machine, blanching&cooking machine,sterilizing machine,

quick freezer,freeze dryer,drying machine,packing machine,vegetables/fruits cutting machine,and complete

production line,etc.The equipment are widely used for fruits,vegetables,aquatic products,meat,pasta,medicine,

pet foods processing factories,and central kitchens as well.

Our company has always been seeking new development,from process requirements,design,production,quality

racking to after-sales service are all controlled by technical engineers. It has strong technical force, excellent manufacturing facilities, advanced technology and stable product quality.

We always adhere to the business philosophy of "Establishing enterprises with integrity and win-win innovation",

and create higher value for customers and society. We have customers all over the world and our products have

been enjoyed a high reputation on overseas market.

Zhucheng Tianshun Machinery Co.,Ltd. is a modern food equipment and machinery manufacturing enterprise which

integrating R & D, production, sales and after-sales services.

Mainly manufactures food frying machine,washing machine,blanching&cooking machine,sterilizing machine,quick

freezer,freeze dryer,drying machine,packing machine,vegetables/fruits cutting machine, and complete production line,etc.

The equipment are widely used for fruits,vegetables,aquatic products,meat,pasta, medicine,pet foods processing factories,

and central kitchens as well.

Our company has always been seeking new development,from process requirements,design,production, quality tracking

to after-sales service are all controlled by technical engineers. It has strong technical force, excellent

manufacturing facilities, advanced technology and stable product quality.

We always adhere to the business philosophy of "Establishing enterprises with integrity and win-win innovation", and

create higher value for customers and society. We have customersall over the world and our products have been

enjoyed a high reputation on overseas market. 5.-Our clients

5.-Our clients 6.-Packing and shipment

6.-Packing and shipment

Packing: internal stretch film (also can be arranged according to customer needs).

Transportation: truck logistics or customer's requirements