Palm Kernel Oil Making Machine,

Henan Huatai Cereals and Oils Machinery Co., Ltd.- Type:Pressing Machines

- Application:All

- Voltage:380V

- Appearance:Vertical

- Press Materials:Cottonseed

- Press Series:Fourth

Base Info

- Model NO.:HT-15TPH

- Condition:New

- Customized:Customized

- Transport Package:Fit for Shipping

- Specification:42000*12000*15000mm

- Trademark:HUATAI

- Origin:Henan

- HS Code:84792000

- Production Capacity:50sets,Month

Description

Basic Info.

Model NO. HT-15TPH Condition New Customized Customized Transport Package Fit for Shipping Specification 42000*12000*15000mm Trademark HUATAI Origin Henan HS Code 84792000 Production Capacity 50sets/MonthProduct Description

Brife Introduction of Huatai Cereals and Oils Machinery Co.,LtdOur belief is "Seiko Winning". Henan Huatai Factory covers an area of 100,000m2, of which the workshop covers an area of over 21600 m2. The headquarters is equipped with 8 standard production workshops, 2 machining workshops and 12 engineering installations. Huatai Machinery has 120 sets of various production and processing equipment, including more than 80 lathes, planers, milling machines and drilling machines, more than 10 sets of shearing equipment, 6 automatic welding machines for submerged arc welding, DC welding machines and AC welding machines. Multiple units are also equipped with various auxiliary equipment and testing equipment. Welcome to visit our factory!

Huatai Products list

- 30~1000T/D rice bran expanding pretreatment process,solvent extracting processing equipment

- 30~600T/D Rice bran First-grade oil refining equipment

- Series rice bran molecular distillation refining primary oil complete equipment

- 30~5000T/D Oil pretreatment, pre-pressing, leaching equipment

- 50~1200T/D Grease refining equipment

- 10~2000T/D Corn deep processing equipment

- 10~1200T/D Palm oil, cottonseed oil refining and separation equipment

- 30~1000T/D Biodiesel equipment

- Rice bran oil, cottonseed oil mixed oil refining equipment

Nut & Kernel Separation Station

Firstly, the wet fiber and wet nut enter the cake breaker conveyor to be cracked, and mostly of the fiber should be separated by pneumatic fiber depericarper system. The nut, little fiber and big impurity will be further separated by the polishing drum. The separated nut should be sent to nut hopper through the pneumatic nut transport system, and then adopt the ripple mill to crack the nut, after cracking, most of the shell and kernel will be separated by cracked mixture separating system, and the rest of mixture of kernel & shell enter to the special clay bath separating system to separate them, after this processing, we could get pure kernel(The shell content in kernel <6%), which should be conveyed to the kernel silo to dry. After dried moisture as 7%, the kernel will be conveyed to kernel storage bin for storage, Usually the dry kernel's capacity ratio is 4%. So it should be collected until enough quantity, and then be sent to the palm kernel oil mill, For the separated shell, it should be conveyed to shell temporary bin as the spare boiler fuel.

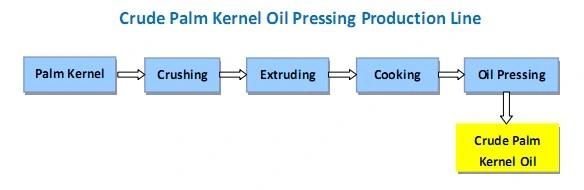

Palm Kernel Oil Pressing Plant Flow Chart:

Palm Kernel Cleaning: It is used for removing the iron impurities, stone, fiber and others. These impurities are bad for machines, especial for the palm kernel oil expeller.

Palm Kernel Crushing: Because the palm kernel is hard and big size, it is required to crash to smaller and even pieces. If once crashing can not reach the requirements, the second crashing is required. Crush palm kernels after softening and drying. The centrifugal crusher breaks nuts and separate palm kernel out completely.

Palm Kernel & Nuts Shell Separation: Both dry and wet separations are available. Wet separation is mostly used in palm kernel separation, on basis of difference of relative density of palm kernel and shell.

Palm Kernel Drying: Fresh kernel contains 20% moisture. Palm kernel has no mildew during transportation and storage while moisture drops below 7%.

Cooking Section: It is used for heating and cooking the crashing materials, to make is suitable for palm kernel pressing, doing like this can help final user get the maximum oil and good quality cakes.

Palm Kernel Oil Pressing: Palm kernel oil pressing processing line is simple with usual oilseeds. The pre-pressing by palm oil pressing machine can obtain 1/4 palm kernel oil, and residual oil need twice pressing.

Crude oil Storage Tank

Oversea Projects of Henan Huatai

| No. | Country | Project Name |

| 1 | Australia | 150T/D Vacuum Drying Equipment |

| 2 | Australia | 100T/D High Material Layer Desolventizer |

| 3 | Bangladesh | 30T/D Rice Bran Making Oil Project |

| 4 | Bangladesh | 100T/D Rice Bran Making Oil Project |

| 5 | Bangladesh | 30TPD Sunflower Seed, Mustard Seed Making Oil Project, 30T/D Fully Continuous Oil Refining Project |

| 6 | Bangladesh | 15T/D Rapeseed Oil Refining Project |

| 7 | Bolivia | 60T/D Soybean Oil Refining Project |

| 8 | Cambodia | 30T/D Rice Bran Making Oil Project |

| 9 | Cameroon | 5T/D Palm Oil Stirring Tank |

| 10 | Congo | 0.5T/H Palm Oil Making Soap Project |

| 11 | Congo | 400T/D Peanut Making Oil Project |

| 12 | Congo | 15T/H Palm Fruit Pressing, 10T/H Palm Oil Refining and Fractionation Project |

| 13 | Congo | 5T/H Palm Fruit Pressing, 5T/D Palm Oil Refining Project |

| 14 | Djibouti | 2T/D Sunflower Oil Dewaxing Machine |

| 15 | Ethiopia | 50T/D Soybean Oil Refining Project |

| 16 | Ethiopia | 100T/D Corn Processing Project |

| 17 | Ethiopia | 15T/D Peanut and Sunflower Seeds Pressing,5T/D Oil Refining Project |

| 18 | Ethiopia | 5T/D Crude Oil Refinery Project |

| 19 | Ethiopia | 250T/D Flax Seed Oil Making Project |

| 20 | Ethiopia | 50T/D Soybean/Peanut oil press and 30T/D Oil Refining Project |

| 21 | Ethiopia | 15T/D Soybean/Peanut oil press and 10T/D Oil Refining Project |

| 22 | Ethiopia | 200T/D Palm oil Deacidification &Deodorization,100T/D Palm Oil Fractionation Project |

| 23 | Ethiopia | 50T/D Sunflower/Cotton Seed, Sesame Oil Press and 20T/D Oil Refining Project |

| 24 | Egypt | 100T/D Soybean Pretreatment and Extraction Project |

| 25 | Egypt | 20T/D Soybean Oil Refining Project |

| 26 | Egypt | 10T/D Cottonseed Oil Refining Project |

| 27 | Estonia | 10T/D Biodiesel Distillation Project |

| 28 | Ghana | 20T/D Corn Flour Production Line Project |

| 29 | Indonesia | 20T/D Coconut Oil Pressing,10T/D Oil Refining Project |

| 30 | Indonesia | 3T/D Fragrant Sesame Oil Project |

| 31 | Indonesia | 3T/D Oil Refining Machine |

| 32 | Indonesia | 20T/D Maize germ oil pressing and 5T/D oil refining project |

| 33 | Kazakhstan | 3T/D High class Cooking Oil Refining Project |

| 34 | Kazakhstan | 120T/D Sunflower Seed Prepressing, Extraction and Refining Project |

| 35 | Kazakhstan | 50T/D Safflower Oil Processing Project |

| 36 | Kazakhstan | 100T/D Soybean Pretreatment ,Oil Press Project |

| 37 | Kenya | 3T/D Pyrethrin Extraction Project |

| 38 | Malawi | 2T/D Oil Refining Machine |

| 39 | Moldova | 3T/D Sunflower Oil Refining & dewaxing Machine |

| 40 | Myanmar | 3T/D Cottonseed Oil Refining Machine |

| 41 | Myanmar | 5T/D Oil Refining Project |

| 42 | Nigeria | 5T/H Palm Fruit and Kernel Pressing Project |

| 43 | Nigeria | 20T/D Palm Oil Refining and Fractionation Project |

| 44 | Nigeria | 50T/D Peanut Pressing, 15T/D Peanut Oil Refining Project |

| 45 | Nigeria | 40T/D Cotton Seed Oil Processing and 15T/D Oil Refining Project |

| 46 | Nigeria | 60T/D Soybean, Peanut, Shea nut Oil Press ,25T/D Oil Refining Project |

| 47 | Peru | 50T/D Cotton Seed Palm Oil Refining Project |

| 48 | Peru | 50T/D Palm Oil Refining and Fractionation Project |

| 49 | Peru | 150T/D Soybean/Palm/Sunflower Oil Refining Project |

| 50 | Russia | 50T/D Soybean Pretreatment, 50T/D Solvent Extraction and 10T/D Soybean Oil Project |

| 51 | Russia | 10T/D Rapeseed Oil Pressing Project |

| 52 | Russia | 10T/D Sunflower/Rapeseed Oil Pressing and 3T/D Oil Refining Project |

| 53 | Rwanda | 10T/D Palm Oil Refining Project |

| 54 | Solomon Islands | 3T/D Coconut Oil Deacidification & Deodorization Project |

| 55 | Sri Lanka | 30T/D Chicken Oil Pressing, 20T/D Chicken Oil Refining Project |

| 56 | Sri Lanka | 5T/D Fish Oil Refining Project |

| 57 | Sudan | 30T/D Peanut Oil Pressing, 15T/D Peanut Oil Refining Project. |

| 58 | Swaziland | 30T/D Oil Refining Machine |

| 59 | Tajikistan | 50T/D Cottonseed Cake Extraction Project |

| 60 | Tajikistan | 50T/D Cottonseed Prepressing Project |

| 61 | Tanzania | 20T/D Sunflower Seeds Pressing, 5T/D Refining Project |

| 62 | Tanzania | 10T/D Sunflower Seeds Pressing, 3T/D Refining Project |

| 63 | Thailand | 10T/H Palm Oil Renovation Project |

| 64 | Thailand | 45T/H Palm Fruit Sterilization Tank |

| 65 | Thailand | 2T/D Palm Oil Refining Project |

| 66 | The Philippines | 30T/D Corn Germ Pressing and Refining Project |

| 67 | The Philippines | 15T/D Corn Processing Project |

| 68 | Turkmenistan | 50T/D Sunflower Seed Pretreatment,30T/D Extraction and 20T/D Refining Project |

| 69 | Ukraine | 30T/D Sunflower cake Extraction Project |

| 70 | Ukraine | 50T/D Sunflower cake Extraction Project |

| 71 | Uzbekistan | 80T/D Sunflower Seed Cake Extraction, 50T/D Sunflower Oil Refining Project |

| 72 | Uzbekistan | 50T/D Sunflower Seed, Soybean, Cottonseed Making Oil Project |

| 73 | Uzbekistan | 100T/D Sunflower Seed Prepressing, Soybean Pretreatment, 100T/D Micro negative Pressure Extraction and 20T/D Grade 1 Oil Refining Project |

| 74 | Uzbekistan | 100T/D Sunflower Seed Cake Extraction,30T/D Semi-continuous Sunflower Seed Oil Refinery and Dewaxing Project |

| 75 | Uzbekistan | 100T/D Sunflower Seed Cake Extraction,50T/D Sunflower Seed Oil Refinery Project |

| 76 | Uzbekistan | 30T/D Sunflower Seed Oil Processing 10T/D Oil Refining Project |

| 77 | Uzbekistan | 100T/D Sunflower Seed Oil Processing 80T/D Extraction Project |

| 78 | Uzbekistan | 50T/D Sunflower Seed Prepress, 50T/D Extraction and 30T/D Refining Project |

| 79 | Uzbekistan | 20T/D Sunflower Cake Extraction,2T/D Sunflower Oil Refinery Project |

| 80 | Uzbekistan | 40T/D Sunflower and Cottonseed Oil Dewaxing Project |

| 81 | Uzbekistan | 50T/D Sunflower Seed,soybean Pre[0[0-z]z]press, 50T/D Extraction and 20T/D Refining Project |

| 82 | Uzbekistan | 30T/D Sunflower Seed Prepress, 20T/D Extraction and 10T/D Refining Project |

| 83 | Uzbekistan | 100T/D Sunflower Seed Prepress, 80T/D Extraction and 40T/D Refining and Dewaxing Project |

| 84 | Uzbekistan | 80T/D Sunflower Cake ,Soybean Flakers Extraction Refining Project |

Customers visiting

Huatai Workshop advance appliances