Bcq250 Full-Automatic Hard and Soft Biscuit Production Line

Shanghai Target Industry Co., Ltd.- Usage:Biscuit

- Power Source:Electric

- Timing Device:Without Timing Device

- Type:Production Line

- Voltage:380V

- Transport Package:Woodenpackage

Base Info

- Model NO.:BCQ250

- Trademark:TGmachine,BCM machine

- Origin:Shanghai

- Production Capacity:8sets,Year

Description

S/N

Name

Qty.

Size(mm)

1

Model III-Flour mixer

1set

1250*780*1300

2

Mixed Dough feeding conveyor

1set

2500*600*1600

3

Biscuit forming machine (hard biscuit )

1set

7600*840*1600

4

Biscuit forming machine(soft biscuit )

1set

1800*840*1200

5

Control console

1set

800*400*600

6

Sugar/salt sprinkling machine

1set

800*650*1550

7

Inlet conveyor

1set

1800*700*1300

8

Tunnel oven(Electric)

24m

24000*1000*1200

9

Outlet conveyor

1set

1800*700*1300

10

Oil spraying machine

1set

1650*650*1550

11

180º turning machine

(can be selected )

1set

3500*1700*800

12

Cooling line

12m

8000*640*700

13

Biscuit stacking machine

(with 6meter packing table)

1set

2000*800*1350

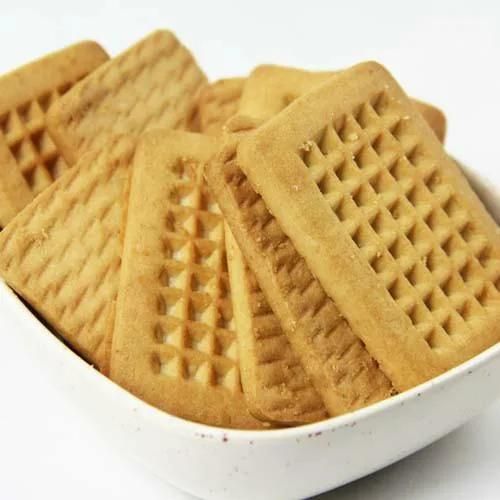

BISCUIT SAMPLE PICTURE:

PROFILE:

Biscuit can be grouped into hard biscuit and soft biscuit , according to the formula, process, and different forming method, Hard biscuit production line is generally composed of a feeding machine(if producing the soda biscuit or chocolate coated biscuit, another lamination process is needed), a set of dough roller, through the dough rolling and dough sheeting, then through the roller cutting machine, rest material recycling device, inlet oven machine, the entire biscuit forming line. In order to increase the biscuit types and characteristics, customers can allocate the sugar & salt sprinkling machine, egg spraying machine, calico printing machine, etc. The oven is to make the formed biscuit into delicious food. You can choose different types of bakery oven (electric/gas/diesel/thermal oil)for baking different types of products.

For soft biscuit and cookie biscuit production line, only the forming machine and inlet oven machine can be the whole forming process.

PROCESSING PROCEDURE:

Flour mixing----Dough sheeting----Biscuit forming----Baking----Oil spraying----Cooling----Stacking----Packing

Company Information

Know about TGMachine Go to TGMachine Choose TGMachine

- Present TGMachine

- Service From TGMachine

- TGMachine's Customers Location Worldwide

Our Services

After-Sale Service For Abroad Customers:

1. Free training of machine installation, operation and maintenance will be provided by our engineer.

2. Some spare parts will be sent with the machine for free. It is available to buy the parts from us forever at low price.

3. We will surpport customers after-service forever by call, email and video etc.

4. If necessary, our engineer is available to go to customer's factory for machine installation and adjustment.

Packaging & Shipping

Wooden Packing:

1. Product production is completed, by the quality inspection department to check

2. After inspection qualified, clean for whole machine

3. Packing:

a. Inside the machine put desiccant

b. Add 6 cm thick foam plate around the machine,Then, winding stretch film for reinforcement, and combined with bubble wrap

c. On wood packaging on the outside of the machine, then use metal reinforcement with steel

4. Container: according to different products for reinforcement.