Gd150TF Brown Sugar Depositing Line (Improved) with High Quality

Shanghai Target Industry Co., Ltd.- Certification:CE, ISO9001

- Automatic Grade:Automatic

- Application:Ice Cream, Candy, Chocolate

- Customized:Customized

- Capacity:150kg,H

- Depositing Speed:15-30n,Min

Base Info

- Model NO.:GD150TF

- Electric Power:16kw,380V

- Total Length:17m

- Max Candy Weight:as Per as Candy Size

- Room Condition:Temp20~25°c

- Transport Package:Wooden Case

- Specification:CE, ISO9001

- Trademark:TGmachine

- Origin:China

- HS Code:84382000

- Production Capacity:150kg,H

Description

Basic Info.

Model NO. GD150TF Electric Power 16kw/380V Total Length 17m Max Candy Weight as Per as Candy Size Room Condition Temp20~25°c Transport Package Wooden Case Specification CE, ISO9001 Trademark TGmachine Origin China HS Code 84382000 Production Capacity 150kg/HProduct Description

GD150TF Brown Sugar Depositing Line(Improved) With high quality

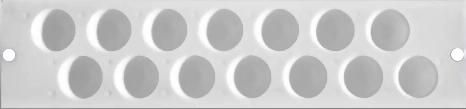

Molds

FEATURES:With 40 years candy experience, Shin Wei Machinery produceed the 5rd generation GD series automatic PLC controlled candy depositing production line .It is an advanced equipment for confectionery production. The set of mechanical, electrical, gas control in one, reasonable and compact structure, high degree of automation; High production efficiency, capable of producing high-quality brown sugar.

The whole line is produced accord to the GMP standard of food machinery,it is not only an ideal equipment which can produce out good quality products with the saving of both the manpower and the space occupied ,but also help the candy manufacturer pass the GMP,HACCP,QS authentication.

TECHNICAL SPECIFICATIONS:

| Model | GD300-TF |

| Capacity(kg/h) | 300 |

| Candy weight | According to the candy size |

| Depositing speed: | 25~30 n/min |

| Cooker powder(electrical heating) | 36KW |

| Compressed air requirement | 0.25m3/min, 0.4~0.6MPa |

| Total powder(electrical heating) | 76kW/380V |

| Total length(m) | 17 |

| Total weight (kg) | 3500 |

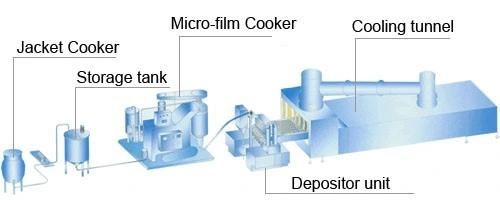

Deposited hard candy processing flowchart(As reference):

Raw material dissolving ->Transporting->Storage->Dosing->Pre-heating->

Micro-film cooking->Discharding->Mixing with favor and color-> Depositing->

Cooling->De-moulding-> Conveying->Packing->Final products

MAIN EQUIPMENT LIST:

The whole line is comprised of cookers, vacuum micro-film syrup cooking unit, depositor, industrial cooling system, gear pumps, dosing pumps, controller and etc.

PROCESS FLOWING LAYOUT CHART: