Gd1200s Servo Driven Hard Candy Depositing Line for Hard Candy

Shanghai Target Industry Co., Ltd.- Certification:CE, ISO9001

- Automatic Grade:Automatic

- Application:Ice Cream, Candy, Chocolate

- Customized:Customized

- Capacity:1000-1200kg,H

- Depositing Speed:45-55n,Min

Base Info

- Model NO.:GD1200S

- Electric Power:16kw,380V

- Total Length:18m

- Max Candy Weight:as Per as Candy Size

- Room Condition:Temp20~25°c

- Transport Package:Wooden Case

- Specification:CE, ISO9001

- Trademark:TGmachine

- Origin:China

- HS Code:84382000

- Production Capacity:1000-1200kg,H

Description

Basic Info.

Model NO. GD1200S Electric Power 16kw/380V Total Length 18m Max Candy Weight as Per as Candy Size Room Condition Temp20~25°c Transport Package Wooden Case Specification CE, ISO9001 Trademark TGmachine Origin China HS Code 84382000 Production Capacity 1000-1200kg/HProduct Description

GD1200S Servo Driven Hard Candy Depositing Line For Hard Candy

FEATURES:We adopt double film boiling system and double depositing unit for GD1200S automatic hard candy machinery to reach a high yield of production. Under the highly centralized automatic control by reducing the manual control to cut down manpower cost. We adopt newly designed long moulds for the depositor in this line, which improves the production efficiency while keeping the same manufacturing cost.

TECHNICAL SPECIFICATIONS:

| Model | GD1200S |

| Production capacity ( kg/h) | 1000-1200kg/H |

| Rated depositing times(n/min) | 25~55 |

| Electric power needed | 5kw/380V |

| Refrigerator | MT120 15,000 kcal/h |

| Compressed air consumption Compressed air pressure | 0.20m3/min 0.4-0.6 Mpa |

| Conditions needed for the cooling system: 1.Room temperature(ºC) 2.Humidity (%) | 20-25 55 |

| Length of the whole line (m) | 18 |

| Gross weight ( Kgs) | Approx.1000 |

Deposited hard candy processing flowchart(As reference):

Raw material dissolving ->Transporting->Storage->Dosing->Pre-heating->

Micro-film cooking->Discharding->Mixing with favor and color-> Depositing->

Cooling->De-moulding-> Conveying->Packing->Final products

MAIN EQUIPMENT LIST:

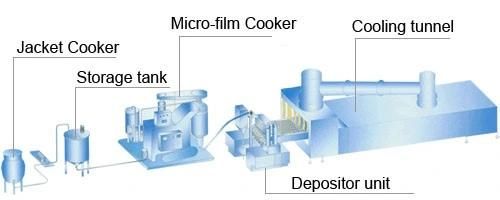

The whole line is comprised of cookers, vacuum micro-film syrup cooking unit, depositor, industrial cooling system, gear pumps, dosing pumps, controller and etc.

PROCESS FLOWING LAYOUT CHART: