High Efficiency Fmfq (S) 80*2 Pneumatic Flour Mill

Henan Institute of Grain Machinery Manufacturing Co., Ltd.- Type:Flour Mill

- Application:Flour, All, Beans, Wheat, Rice flour

- Voltage:380V

- Condition:New

- Customized:Customized

- Capacity:According to Customers′ Need

Base Info

- Model NO.:FMFQ(S) 80*2

- Warranty:1 Year

- Place of Origin:Henan, China (Mainland)

- Supply Type:Manufacturer

- Transport Package:Seaworthy Wood Case

- Specification:CE, ISO, SGS

- Trademark:HNLY

- Origin:Henan Zhengzhou

- HS Code:8437800000

- Production Capacity:8000 Sets,Year

Description

Basic Info.

Model NO. FMFQ(S) 80*2 Warranty 1 Year Place of Origin Henan, China (Mainland) Supply Type Manufacturer Transport Package Seaworthy Wood Case Specification CE, ISO, SGS Trademark HNLY Origin Henan Zhengzhou HS Code 8437800000 Production Capacity 8000 Sets/YearProduct Description

high efficiency FMFQ(S) 80*2 pneumatic flour millPneumatic mill is the main equipment of wheat flour mills, which is adjusted according to the the coming material's characteristics. Clutch brake from the Mill grinding roll and operating of feed rolls are manually controlled.

Structure features:

(1) It has adopted new design and compact structure affording good performance and high efficiency.

(2) The machine is made of mangnese plate with cast iron base to work smoothly.

(3) Synchronous belt drive and eccentric wheel make an efficient structure to extend its severice life.

(4) Manual and pneumatic control makes an easy operation.

Main Technical Performance Parameter Table

| Model | FMFQ(S)50*2 | FMFQ(S)60*2 | FMFQ(S) 80*2 | FMFQ(S)100*2 |

| Grinding roller specifications(mm) | φ250*500 | φ250*600 | φ250*800 | φ250*1000 |

| Grinding roller using range(mm) | φ250 - 220 | φ250 -220 | φ250 - 220 | φ250 - 220 |

| Fast roller speed(rpm) | 550 | 550 | 550 | 550 |

| Actuating pressure(mpa) | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 |

| Mill gas consumption (m3/h) | 0.06-0.08 | 0.06-0.08 | 0.06-0.08 | 0.06-0.08 |

| The speed of the roller speed ratio | 2.5:1 | 2:1 | 1.5:1 | 1.25:1 |

| Power(kw) | 5.5-15 | 5.5-18.5 | 7.5-22 | 11-22 |

| Total weight(kg) | 2400 | 2700 | 2900 | 3200 |

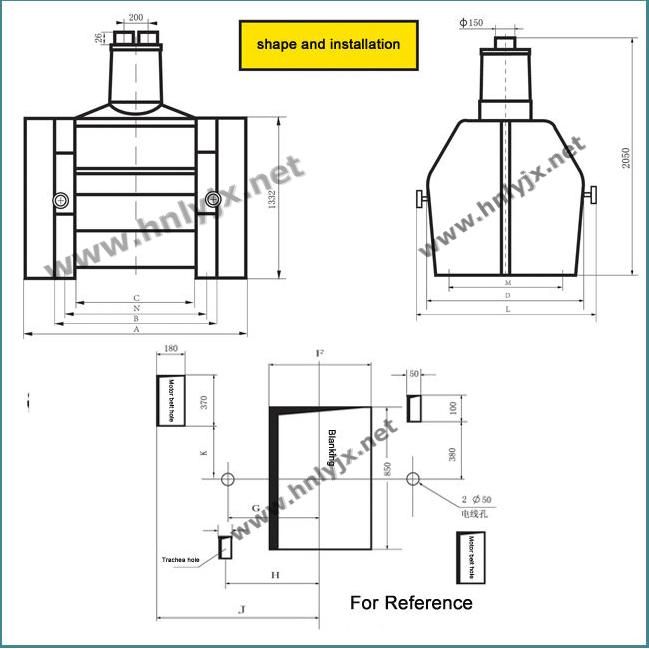

| Dimension(L*W*H)(mm) | 1400*1410*1850 | 1500*1410*1850 | 1700*1410*1850 | 1900*1410*1850 |

The process of flour milling:

The process of flour milling (from corn to milled into corn flour) usually consists of the following:

1. corn storage (silos, or warehouse) ----------

2. cleaning system (sifter, destoner, seprater, magnet, scourer, etc) -------

3. dampening (dampener, conditioning silos, etc) -----

4. milling system (roller mill, plansifter, purifier, impact detacher, etc.) ------

5. Flour pressure and blending system (if need) ----------

6. flour packing and stacking