China Huatai Brand Advance Design Complete Sunflower Oil Making Machine

Henan Huatai Cereals and Oils Machinery Co., Ltd.- Type:Refining Plant

- Application:Palm Fruits

- Voltage:380V

- Appearance:Horizontal

- Press Materials:All Grain Materials

- Press Series:First Class

Base Info

- Model NO.:Huatai 30-5000T,D

- Condition:New

- Customized:Customized

- Oil Yield:50-1500t,D

- Oil Color:Transparent

- Staff Training:Free

- Warrantity Period:12 Months

- Oil Grade:1, 2, 3, 4, Grade According to Your Need

- After-Sale Sevice:Engineer Available to Service Machine Overseas

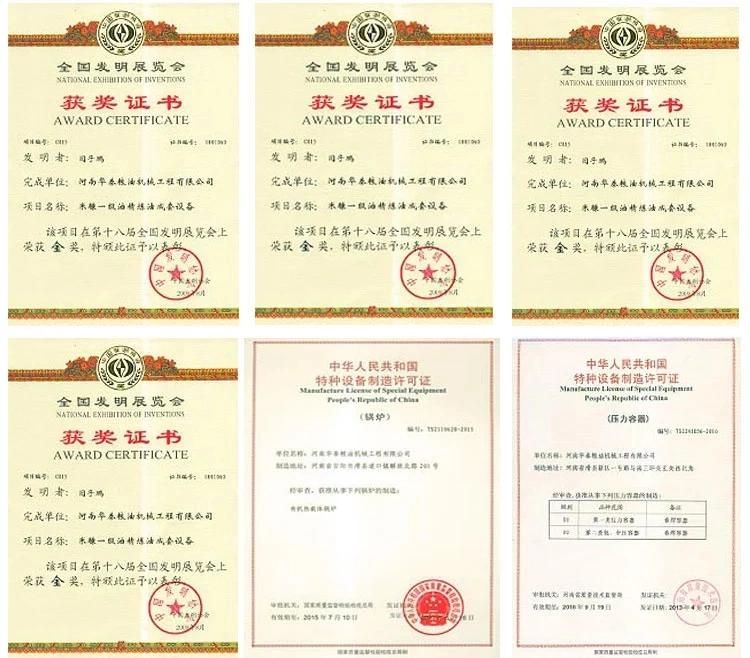

- Patent:Yes, 22 Patents Certification

- Certifications:CE, SGS, ISO9001, BV, etc

- Usage:Used to Refine The Crude Palm Oil

- Transport Package:Nude Packing, Transportated in Container

- Specification:According to your needs

- Trademark:HUATAI

- Origin:Henan, China

- HS Code:847920000

- Production Capacity:20 Set,Month

Description

Basic Info.

Model NO. Huatai 30-5000T/D Condition New Customized Customized Oil Yield 50-1500t/D Oil Color Transparent Staff Training Free Warrantity Period 12 Months Oil Grade 1, 2, 3, 4, Grade According to Your Need After-Sale Sevice Engineer Available to Service Machine Overseas Patent Yes, 22 Patents Certification Certifications CE, SGS, ISO9001, BV, etc Usage Used to Refine The Crude Palm Oil Transport Package Nude Packing, Transportated in Container Specification According to your needs Trademark HUATAI Origin Henan, China HS Code 847920000 Production Capacity 20 Set/MonthProduct Description

Henan Huatai Cereals And Oils Machinery Co., Ltd, - International Leading Manufacturing Expert of Grain and Oil Machines

(short for HHFOME) is located in the Industry cluster of Huaxian, Henan Province which covering 100, 000.00and have more than 580 staffs. We are a large-scale grain and oil equipments production enterprise which specialized in researching, designing, manufacturing, installation. Since now we have got 22 items national patents, 6 international prizes, etc. Our equipments have got ISO9001, SGS, CE, IAF and CNAS certifications. Also we have been exported to Bolivia, Sudan, Kazakhstan, Russia, Tajikistan, Malaysia, Indonesia, Bangladesh, Vietnam, Thailand, Burma, etc. All of our members will try our best to help you build a powerful and most suitable plant to save your costs.

Main Projects Scope:

-----30-5000T/D oilseeds pretreatment project

-----30-5000T/D oilseeds extraction project

-----10-500T/D crude oil refining project

-----10-500T/D crude oil fractionation project

-----Oil interesterification project

-----Oilseeds protein, phospholipid project

-----Natural pigment extraction project

-----Grain deep processing project

Typical Project:

----30-1000T/D rice bran pretreatment, expanding, extraction project

----30-600T/D rice bran oil refinning project

----150-1000T/D cottonseed dephenolizing protein

----10-1000T/D palm fruit oil pressing project

----10-500T/D Non acid method biodiesel production project

----10-2000T/D corn deep processing pjoject

Newest Technology:

---Energy saving oil vacuum deodorization technology

---Concentrated protein extraction technology

---Mixed oil extraction technology

---Mixed oil refining technology

---Molecular distillation technology

---Broken rice desaccharification technology

---Continuous lignite extraction technology

Service Police and Technical Support

Generally, we guarantee all equipments are completely new and unused, and under normal operation conditions the warranty period would be 12 months after installation or 18 months from the date of shipments whichever comes first.

Our equipment would be shipped in containers. Equipments too large for containerized shipment would be covered and protected from sea water damage.

We can send experienced and qualified engineers (electrical engineer and mechanical engineer) to the Buyer's site for supervision of equipment installation and commissioning. And after the plant had been successfully commissioned, our engineer will stay to train the buyer's plant personnel in process operations and equipment maintenance by buyer's request.

Our company has applied the automatic control system with advancement, security, reliability into the pretreatment, extraction, refining and fractionation in large oil plants. For its application in automatic control system, it can control the production in the entire workshop and monitor the operational status of each device by controlling the computer terminals in the room. One person only can operate the entire workshop, with efficient production management. It has greatly reduced the production cost and improved the management efficiency.

1) Using vacuum filter, it is able to simply filter the crude oil after pressing

2) It is able to save labour, about 60%. One or two person is needed per machine

3) Protecting the environment, comparing with the traditional oil press machine, it is about to meet the standard of green environment.

4) Low investment, more profit

Note: If you have any questions about the palm oil refinery plant, you can just feel free to ask us. All of our teams will try our best to offer most suitable solutions for you.

| Meal Residue | ≤1% |

| Solvent residue in leaching meal | <600PPM |

| Solvent residue in leaching oil | <300PPM |

| Solvent Consumption | ≤3-4Kg/T |

| Power Consumption | ≤12Kwh/T |

| Steam Consumption | ≤320 Kg/T(6kgf/cm²) |