Vegetable Broccoli Cauliflower Arugula Salad Lettuce Cutter Washer Cleaning Dryer ...

Foshan Wanlong Machinery Co., Ltd.- Type:Dryer

- Voltage:220V

- Power:1.5KW

- Customized:Customized

- Name:Vegetable Spin Dryer

- Speed:1-1400r Adjusted

Base Info

- Capacity:15kg Per Time

- Plastic Basket:One Machine Goes with 3 Sets

- Working Time:Adjusted

- Material:SUS304

- Transport Package:Wooden Case

- Specification:1.2cbm

- Trademark:wanlong

- Origin:China

- HS Code:8438600000

- Production Capacity:15kg Per Time

Description

1.Capacity: 600 -800kg/ hr.

2.Digital Control the cutting size by 2 inverters.

3.shredder, dicer, slice shape available.

5.cutting size can be adjusted excactly by double inverter.

6.cutting size:1-60mm(adjustable)

7. It can cut leafy vegetables scallion, garlic,leek,celery,Chinese,cabbage, spinage, lettuce, leek, celery, etc. into slice or slice shape.

Also good for root vegetables like carrot, turnip, potato, taro, sweet potatoes, bamboo shoot, onion, eggplant, apple, ginger, onion, into strip, slice or cube shape by changing the blades.

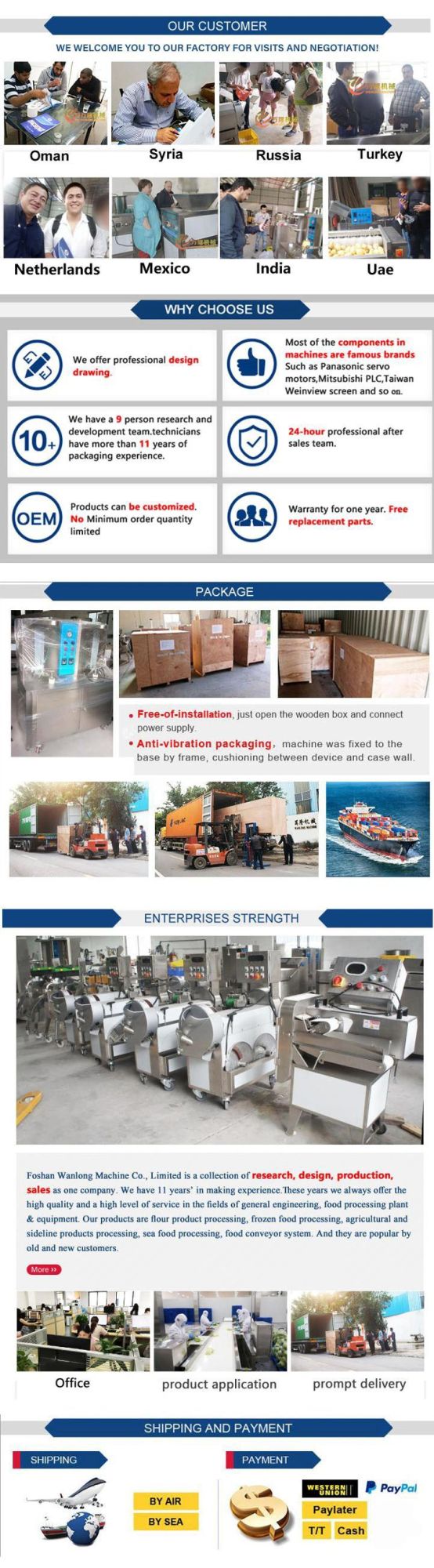

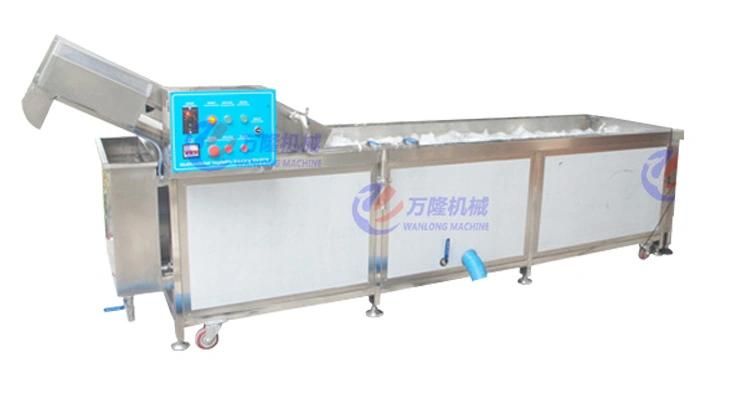

Vegetable Washer

- Ozone sterilization

- adjustable air (bubble) inlets

- adjustable circulating water inlets

- removable bottom tray

- spray rinsing

- adjustable speed and tiltable conveyor

capacity: 800kg/h

voltage: 380V/50hz/3 phase

power: 3kw

dimension: 3700*960*1500mm

Note: you can also choose another model Vegetable Washing Machine in larger capacity.

Model No:TS-15

Voltage :220V/380V

Power :1.5KW

Output:10-15KG/per times

Speed :1450r/min

Size :900×600×960mm

rotation speed: 1-1400r adjusted

Feature:

(1) Using frequency conversion technology and photoelectric?sensor?technology, centrifugal dehyration principle.

(2)Machine comes with PLC control panel, which sets dehydrating time and rotation speed, makes running smoothly.

(3) Dehydrating time and the speed can be adjusted.

Description:

1. This line is suitable for processing leaf vegetables like cabbage, lettuce, spinach etc.. Capacity can reach

around 800kg/h.

2. From the inspecting to drying steps, it is a smooth processing flow, saving lots of labor cost,

with high efficiency.

3. Suitable for the food processing factory or food distribute center.