High-Automation Macaroni Extruder Machine Italian Pasta Making Production Line

Jinan Delon Machinery & Equipment Co., Ltd.- Certification:CE, ISO9001

- Power Source:Electric

- Process:Mild Processing

- Application:Ice Cream, Popcorn, Chips, Biscuit

- Customized:Customized

- Transport Package:Wooden Packing

Base Info

- Model NO.:DL3000-100,DL 75

- Specification:19X3X3m

- Trademark:DELON

- Origin:Jinan China

- HS Code:8438800000

- Production Capacity:10 Sets,Week

Description

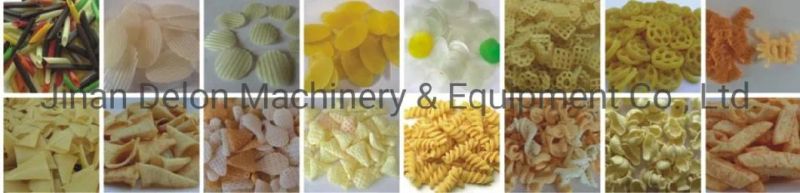

High-Automation Macaroni Extruder Machine Italian Pasta Making Production Line is produced by single-screw extruder through extruding cooking; the pellet can be different shapes like shell, spiral, square tube, circle tube, and so on. After drying, the pellet needs frying to get expanded.

The basic principle and processing method of making the macaroni surface are the same as the noodles, and the principle and method of forming are completely different from the noodles. The macaroni is extruded, and its biggest advantage is that it can replace various molds, and extrude hollow or solid round noodles and various varieties of shells, letters, hanging flowers, and wheels. 1] .

Automatic Best Price Spaghetti Macaroni Noodle Making Machine Pasta Production Line Process flow

1 Long Tongxin: The production process of Changtongxin is:

Raw materials→first time and face→second time face→extrusion→hanging bar→pre-drying→main drying→cooling cutting→packaging→product

2 short macaroni (snail shell): The production process of short macaroni is:

Raw materials→first time and face→second time face→extrusion→drying→cooling→packaging→product [1]

Automatic high quality Italy macaroni production line Main process operation points

1 and surface: The process requirements are basically the same as the production of noodles. It takes 20 to 30 minutes to make the two-face time of the long heart. In the second time, the vacuum treatment should be carried out under the vacuum degree of 0.079-0.086 MPa to remove the air in the dough, so that the extruded noodle tissue is tighter and not easy to break, improving the appearance of the product, improving the transparency and improving the cooking performance. Short macaroni does not require vacuum. Both sides use tap water at room temperature.

2 Extrusion: The dough that has been and has been squeezed into a variety of shapes by passing through a squeeze cylinder and an extrusion die. The working pressure of the extrusion cylinder is generally 7.8 to 11.8 MPa. The temperature of the dough during extrusion should preferably not exceed 40 to 48 °C. In order to prevent the high temperature extrusion from causing the dough to rise too high, it is necessary to cool the extrusion cylinder with cooling water, the inlet water temperature is preferably 15 ° C, and the outlet water temperature is controlled within 34 ° C.

3 drying: the long macaroni is also hanging dry. However, the drying method differs depending on the shape of the molding method and the shape of the product and the noodles. The famous Italian macaroni drying technology is summarized as: "Keeping constant high humidity is the key to ensuring product quality." This is consistent with the "moisturizing drying" of the noodles, which means that the relative humidity of each drying stage is constant. Italian macaroni drying including pre-drying and main drying

Q:Are you manufacturer?

A: Yes, we are manufacturer, welcome to visit our factory and check the machines.

Q: Can you design new mold for us if we have good idea?

A: Yes,we can design new mold for you according to your original market needs.

Q:Can you help us to design the whole line if we provide the layout of our factory?

A:Yes,we can provide you machine layout at your factory after get your factory details.

Q: What information should I provide, if I want a quotation?

A:The kind of machine you choose, or offer me the kinds of food you will produce.

1> Your production capacity requirement.

2>Provide us your production details, then we give professional suggestion to you.

Q: Why choose us?

A: Professional technology, we have been engaged in manufacturing food processing machine for many years, accumul ating rich experience and enjoying high reputation.

1>Fast delivery and good service.

2>All the machines are strictly inspected before making shipment.

3>Alibaba assessed supplier.

4>Provide basic formula.