Mineral Drinking Water Shrink Wrapping Packaging Machine Full Production Line

LangFang YongChuang Packaging Machinery Co., Ltd.- After-sales Service:7*11, Oversea Service Available

- Warranty:1 Year

- Processing Material:Animal Raw Materials, Forest Products, Special Agricultural Products, Garden Products, Agronomic Products, Natural Ingredients

- Application:Pet Food, Chocolate, Ice Cream, Vegetable, Fruit, Dairy, Beverage

- Customized:Customized

- Certification:CE, ISO9001

Base Info

- Model NO.:LC-MBS30

- Power Source:Electric

- Automatic Grade:Automatic

- APP:Water Beverage Juice Drink

- Transport Package:Standard Export Packaging

- Specification:16270*1600*2500 mm

- Trademark:Young Chance Pack

- Origin:China

- HS Code:8422400000

- Production Capacity:2 Pieces,Month

Description

Containers and specificationsProject Name: Full Automatic Complete Mineral Water 2000-20000bph Production Line PH≥4.6drinking water material shape Filling volume(ml) Filling level(mm) Neck type PET Bottle Square or Round Bottle 100-2000ml Distance from bottle neck

According request As request Adjustable specifications of the bottle type Middle Mould Base: Bottle diameter ≤105mm Bottle Height≤335mm Customers need to buy additional change-over parts for the different bottles.

If using square bottles, then bottle separating system will be added. Container Label & Control Mode Packaging system Palletizing system Hot Melt Roll-Fed

PVC Shrink Label

Full Label/ Half Label

Manual / Automatic Packing system Min, Spec. Manual

Low position gantry palletizer

Robot Palletizer

High position gantry palletizer

Single Arm Palletizer

Manual Palletizer Manual

Film shrinker

Wrap Around packer

Robert Packing Machine 1*2

2*3

3*4

4*6

3*5 User Ambient Conditions: Temperature:10~40ºC;Humidity:No dew User Electrical Supply Specification Voltage:380V±5%, 3phase; Frequency:50HZ±1%

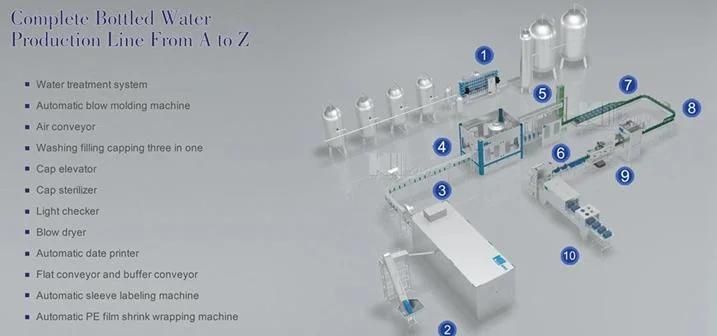

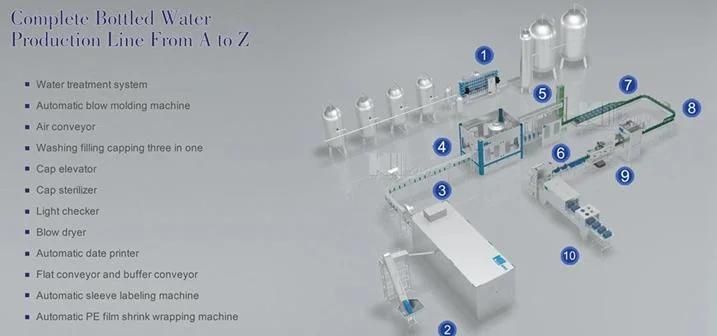

We provide the Complete plant turnkey project for pure water production line including:

1.Water Treatment System, (Water Filtration)

2.Bottle Blowing Machine,(Making plastic bottles)

3.Air Conveyor,(Transport empty bottles)

4.Water Filling Machine ,(Filling water into bottles)

5.Cap elevator, (Transport cap)

6.Blow dryer, (Blow dry water)

7.Flat Convey, (Transport bottle)

8.Code Sprayer,(Printing the date on the bottle water)

9.Labeling Machine ,(Labeling in bottled water)

10.Bottle Shrink Wrapping Machine, (package the bottle water)

11.injection molding machines,(for pet preform)

It is suitable for producing PET plastic bottles from: 250-2000ml;

Both round bottle and square bottle are available.

Material: PET Preform, Cap, Raw Water, PVC Label, Roll PE film

Bottling Line for Natural Mineral Drinking Water, Pure Water, Spring Water.

Flow chart :

Automatic bottle blowing machine --> Air conveyor system-->Washing,filling ,capping 3in1 machine-->Conveyor system-->Automatic sleeve labeling machine-->Automatic film shrink packing machine/Carton packing machine

Brief Introduction

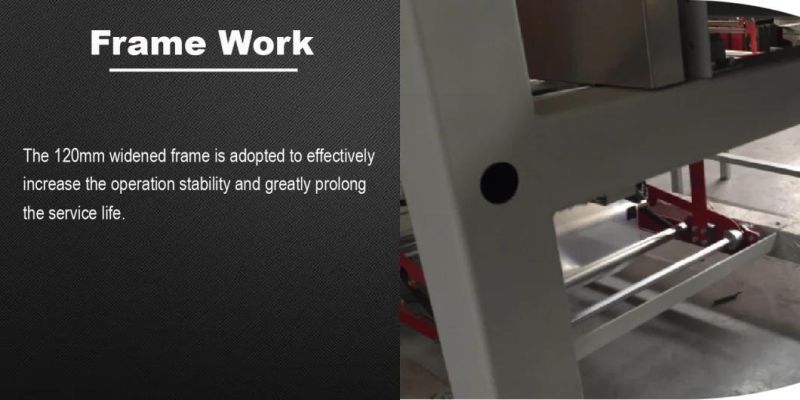

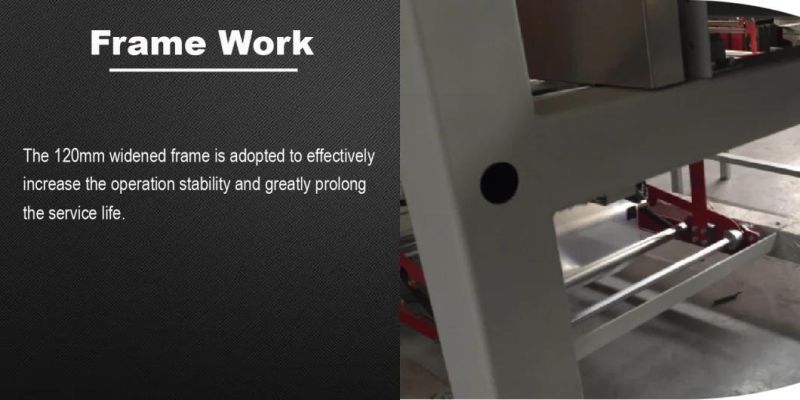

As a high-production packaging equipment, LC-MBS30 One-piece Heat hrink Film Wrapping Machine is designed and manufactured with high efficiency and continuous operation based on the characteristics of heat shrinkable packaging film. It can arrange, set up a single product (such as PET bottle), set up a group, push the bottle and wrap the film, and finally form a collection package by heating shrinkage and cooling. The products after packaging are firm, regular and beautiful in appearance and cost saving.

Machine Model LC-MBS30 Packing Speed 30 Packs / Minitue Machine Dimension (mm) 16270×1600×2500 Max Packing Size (mm) 460×280×350 Shrink Tunnel Dimension (mm) 2500×700×450 Conveyor Belt Width (mm) 610 mm Voltage / Power 3 Phase 5 Line 380V 54 KW Air Consumptioni 0.3 m3 / min Air Pressure 0.6 - 0.8 Mpa Machine Weight 4500KG

3) Using advanced constant temperature membrane heat binding technology in the world with clear and secure seal.

4) The quick seal cooling structure guarantee that the seal has a higher strength even if under high speed production condition.

5) Adopt with PLC automatic program circulation control with stable and reliable performance.

6) The original imported guide bar cylinder guarantee correct operation and durable.

7) The inductive switch controls the membrane transfer system to reliably adjust and control the membrane transfer length with less loss.

8) All the transfer system is controlled by frequency changing devices With stable and smooth transfer speed.

9) Unique thermal passage with 2 sets of centrifugal thermal air circulation system that has an equal heat distribution with beautiful and secure shrinkage effect.

10) 3 layers of heat insulation treatment with good insulating property, quick temperature rise and energy saving.

11) The enhanced cooling shaping passage can quickly turn the packaging membrane into high strength status that is conveniently stored and transported.12) It is easy to change the packaging combination and bottle type to integrate the multi-function into one machine.

Machine Applications

- PET Bottled and Tin Canned products. - Mineral Water, Purified Water, Drinking Water, Beverage, Beer, Juice, Dairy, Condiment, food,etc.

Business Opportunities

As one of the most competitive brands in the packaging industry, Young Chance Pack has successfully provided a complete solution for all kinds of drinking water, beverage, juice, beer, dairy, condiment, food industries.

Order Information

To help us make sure this model is suitable for you, please kindly provide the following information with your inquiry:

1) Details of your product (Dimensions, Photos and Drawings)

2) Packaging Combination for each pack (2×3, 3×4, 4×6 or others)

3) Packaging Capacity Required (How many bottles/cans for each hour on the current/planned production line)

4) Packaging Expectation (Photo of packed product shall be very helpful)

5) Packaging Automation Level (Semi-automatic or Complete Automatic)

6) The Layout Drawing of workshop (Optional, just help us prepare arrangement of the machine)

7) The Height of current production line (Optional, just help us confirm the height of conveying system)8) Other usful information which might helpful.

According request

If using square bottles, then bottle separating system will be added.

PVC Shrink Label

Full Label/ Half Label

Manual / Automatic

Low position gantry palletizer

Robot Palletizer

High position gantry palletizer

Single Arm Palletizer

Manual Palletizer

Film shrinker

Wrap Around packer

Robert Packing Machine

2*3

3*4

4*6

3*5

We provide the Complete plant turnkey project for pure water production line including:

1.Water Treatment System, (Water Filtration)

2.Bottle Blowing Machine,(Making plastic bottles)

3.Air Conveyor,(Transport empty bottles)

4.Water Filling Machine ,(Filling water into bottles)

5.Cap elevator, (Transport cap)

6.Blow dryer, (Blow dry water)

7.Flat Convey, (Transport bottle)

8.Code Sprayer,(Printing the date on the bottle water)

9.Labeling Machine ,(Labeling in bottled water)

10.Bottle Shrink Wrapping Machine, (package the bottle water)

11.injection molding machines,(for pet preform)

It is suitable for producing PET plastic bottles from: 250-2000ml;

Both round bottle and square bottle are available.

Material: PET Preform, Cap, Raw Water, PVC Label, Roll PE film

Bottling Line for Natural Mineral Drinking Water, Pure Water, Spring Water.

Flow chart :

Automatic bottle blowing machine --> Air conveyor system-->Washing,filling ,capping 3in1 machine-->Conveyor system-->Automatic sleeve labeling machine-->Automatic film shrink packing machine/Carton packing machine

Brief Introduction

As a high-production packaging equipment, LC-MBS30 One-piece Heat hrink Film Wrapping Machine is designed and manufactured with high efficiency and continuous operation based on the characteristics of heat shrinkable packaging film. It can arrange, set up a single product (such as PET bottle), set up a group, push the bottle and wrap the film, and finally form a collection package by heating shrinkage and cooling. The products after packaging are firm, regular and beautiful in appearance and cost saving.

3) Using advanced constant temperature membrane heat binding technology in the world with clear and secure seal.

4) The quick seal cooling structure guarantee that the seal has a higher strength even if under high speed production condition.

5) Adopt with PLC automatic program circulation control with stable and reliable performance.

6) The original imported guide bar cylinder guarantee correct operation and durable.

7) The inductive switch controls the membrane transfer system to reliably adjust and control the membrane transfer length with less loss.

8) All the transfer system is controlled by frequency changing devices With stable and smooth transfer speed.

9) Unique thermal passage with 2 sets of centrifugal thermal air circulation system that has an equal heat distribution with beautiful and secure shrinkage effect.

10) 3 layers of heat insulation treatment with good insulating property, quick temperature rise and energy saving.

11) The enhanced cooling shaping passage can quickly turn the packaging membrane into high strength status that is conveniently stored and transported.12) It is easy to change the packaging combination and bottle type to integrate the multi-function into one machine.

Machine Applications

- PET Bottled and Tin Canned products. - Mineral Water, Purified Water, Drinking Water, Beverage, Beer, Juice, Dairy, Condiment, food,etc.

Business Opportunities

As one of the most competitive brands in the packaging industry, Young Chance Pack has successfully provided a complete solution for all kinds of drinking water, beverage, juice, beer, dairy, condiment, food industries.

Order Information

To help us make sure this model is suitable for you, please kindly provide the following information with your inquiry:

1) Details of your product (Dimensions, Photos and Drawings)

2) Packaging Combination for each pack (2×3, 3×4, 4×6 or others)

3) Packaging Capacity Required (How many bottles/cans for each hour on the current/planned production line)

4) Packaging Expectation (Photo of packed product shall be very helpful)

5) Packaging Automation Level (Semi-automatic or Complete Automatic)

6) The Layout Drawing of workshop (Optional, just help us prepare arrangement of the machine)

7) The Height of current production line (Optional, just help us confirm the height of conveying system)8) Other usful information which might helpful.