Kenya 30t/D Maize Milling Machine for Sale

Shijiazhuang Hongdefa Machinery Co., Ltd.- Type:Flour Mill

- Application:Flour

- Voltage:380V

- Appearance:Vertical

- Press Materials:Corn

- Press Series:Fourth

Base Info

- Model NO.:30T,D

- Condition:New

- Customized:Customized

- Color:Depend on Client Need

- Dust:Less Than 10mg,M3

- Warranty Time:1 Year

- Noise:Less Than 85 Db

- Flour Yield:75%-85%

- Structure:Steel Frame Structure, Storied Building

- Capacity:30t,D

- Capacity Range:10t,D-500t,D

- Name:Maize Miling Machine

- Power:111kw

- Transport Package:Suitable for Sea Transportation and Container Load

- Specification:30T,D

- Trademark:HDF

- Origin:Hebei China

- HS Code:84378000

- Production Capacity:100sets,Year

Description

Basic Info.

Model NO. 30T/D Condition New Customized Customized Color Depend on Client Need Dust Less Than 10mg/M3 Warranty Time 1 Year Noise Less Than 85 Db Flour Yield 75%-85% Structure Steel Frame Structure, Storied Building Capacity 30t/D Capacity Range 10t/D-500t/D Name Maize Miling Machine Power 111kw Transport Package Suitable for Sea Transportation and Container Load Specification 30T/D Trademark HDF Origin Hebei China HS Code 84378000 Production Capacity 100sets/YearProduct Description

Kenya 30t/D Maize Milling Machine corn flour mill machine for saleThe 30T/D Maize Milling Machine can process low-fat flour, corn java, corn germ, feedstuff and so on. We can get other kinds of corn food, such as fast food congee, corn oil if can made further process. The low-fat corn flour, corn java are not only the ideal material of beer factory, wine factory, sugar factory and food factory, but are the healthy food for improving the lives of the residents of the town.

The main details of 30T/D Maize Milling Machine:

1. Production capacity: 30tons corn/24h

2. Extraction rate:

1)Maize rice: 35-40%

2)Maize fine flour: 30-40%

3)Maize bran and Fodder flour: 20-25%

3. Workshop: (L× W× H)24× 7.5× 6m

4. Power supply: About111kW

5. Total weight of the equipment: 12T

5. Container: 40'

7. Installing time: One to two months.

| Type | Capacity | Flour extraction | power | Workshop | Container(ft) |

| 6FYDT-5T | 5t/24h | Fine flour 75-85% | 15kw | 10m/5m/5m | 20*1 |

| 6FYDT-10T | 10t/24h | Fine flour 75-85% | 23kw | 10m/5m/5m | 20*1 |

| 6FYDT-12T | 12t/24h | Fine flour 75-85% | 55kw | 16m/6m/5m | 40*1 |

| 6FYDT-15T | 15t/24h | Fine flour 75-85% | 80kw | 18m/5m/5m | 40*2 |

| 6FYDT-25T | 25t/24h | Fine flour 75-85% | 95kw | 18m/5m/5m | 40*2 |

| 6FYDT-30T | 30t/24h | Fine flour 75-85% | 95kw | 26m/8m/5m | 40*2 |

| 6FYDT-50T | 50t/24h | Fine flour 75-85% | 135kw | 27m/9m/7.5m | 40*2 |

| 6FYDT-100T | 100t/24h | Fine flour 75-85% | 240kw | 30m/9m/10m | 20*1 40*4 |

FAQ

Q1. Does the maize mill line can produce different kind of maize meal,maize flour same time?

Yes,the maize mill line can produce different size maize meal or maize flour at same time at one production line

Q2. Does the maize mill line can running with Generator?

Yes,the maize mill line can running with Generator

Q3. Does the maize meal packing machine can pack different bags?

Yes,the packing machine can pack 1kg-5kg;5kg-20kg,12.5kg-25kg,50kg

Q4. Does the maize mill line can processing maize and wheat same time?

No,it is because the maize and wheat Physical Characteristics is different,like the shape,the hardness,all are different,and the final product flour size is also different. The cleaner,the roller mill parameter,the plansifter sieve all are different.

As professional manufacture for maize meal or flour,cannot processing maize and wheat same time.

Maize flour mill machine for newest technology.

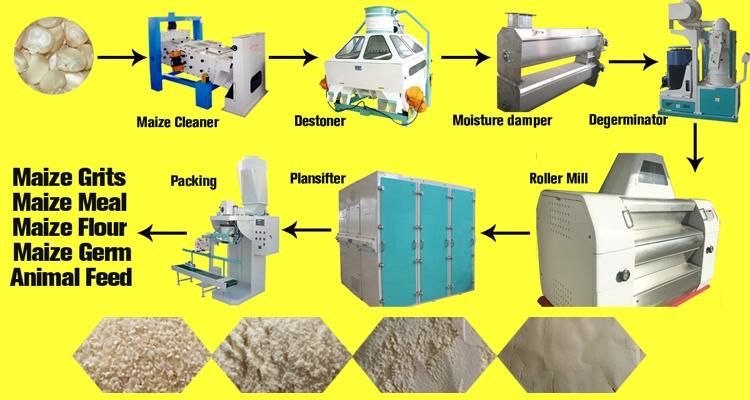

With four steps processing:MAIZE CLEAN-MAIZE DEGERMINATING-MAIZE MILLING-MAIZE MEAL PACKING.

Newest technology as following:

1.Stainless steel double Moisture damper;

2.Degerminator(Tech same as Japan Satake);

3.Stainless steel Magnetic Separator;

4.Quality Roller mill;

5.Double sifter series;

6.Pipes Stainless steel (in milling section where contact with material)

Our Services

The superior service for complete set of Flour mill line---HONGDEFA MACHINERY

Pre-sale

1 Customers choose the model you are interested

2 HDF Machinery Team design according to yours' requirements

3 HDF train technical personnel of you

4 HDF send engineering and technical personnel for site planning and design the best flour mill project

Sale

1.Flour mill project acceptance.

2.HDF help you drawn up construction scheme.

After-sale

1.Branch offices

We have set up branch offices in Australia,Pakistan,Brazil,South Africa,Zambia,Congo,Ethiopia.

Agent in Kenya,Egypt,Tanzania etc..

2.Engineer visit

Experienced engineers do the installation guide,free trainning operation,test flour mill machine.

3.Spare parts

Supply one year spare parts for the flour mill line as free.

Contact detail information :

Ms Lila Wei

Mob:0086-15931139230