Yeast Propagation Tank Beer Brewing Brewery Equipment

Wenzhou Jinggong Machinery Equipment Co., Ltd.- Application:Beverage, Beer Brewery

- Customized:Customized

- Certification:CE, ISO9001, PED

- Power Source:Electric

- Automatic Grade:All Available

- Propagation Method:Two or Three Tanks Method

Base Info

- Control System:Self-Control

- Inner Surface Polish:Less Than 0.4μm

- Cleaning Method:CIP Cleaning

- Sensor:Temperature , Pressure Sensor

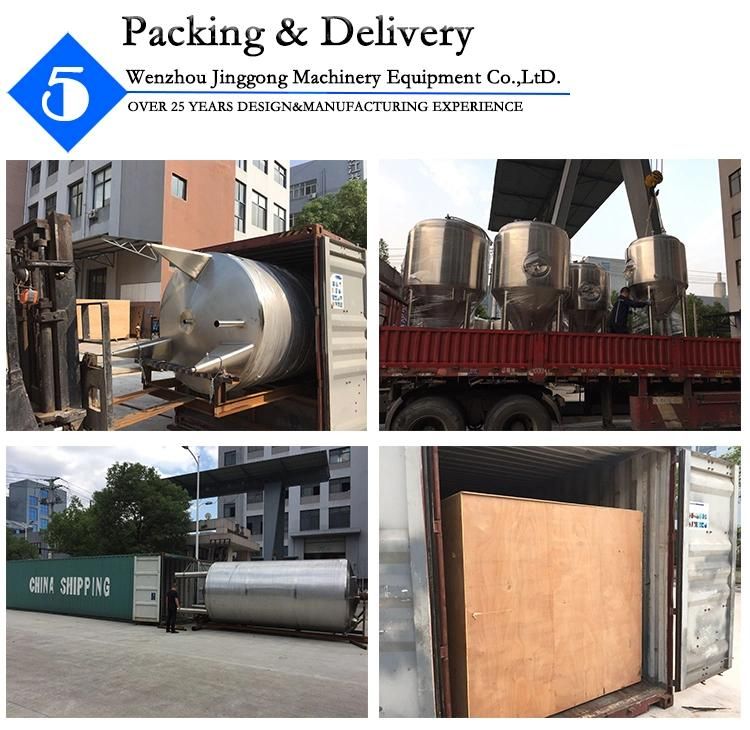

- Transport Package:Wooden Box

- Trademark:Jinggong

- Origin:Zhejiang, China

- HS Code:8438400000

- Production Capacity:20 Sets,Year

Description

Basic Info.

Control System Self-Control Inner Surface Polish Less Than 0.4μm Cleaning Method CIP Cleaning Sensor Temperature / Pressure Sensor Transport Package Wooden Box Trademark Jinggong Origin Zhejiang, China HS Code 8438400000 Production Capacity 20 Sets/YearProduct Description

Our yeast propagation system/equipment is customized based on actual demand, targeted design to eradicate any contamination and culture pure healthy yeast with high activity. The whole design strictly follows sanitary standard.

General information of product:

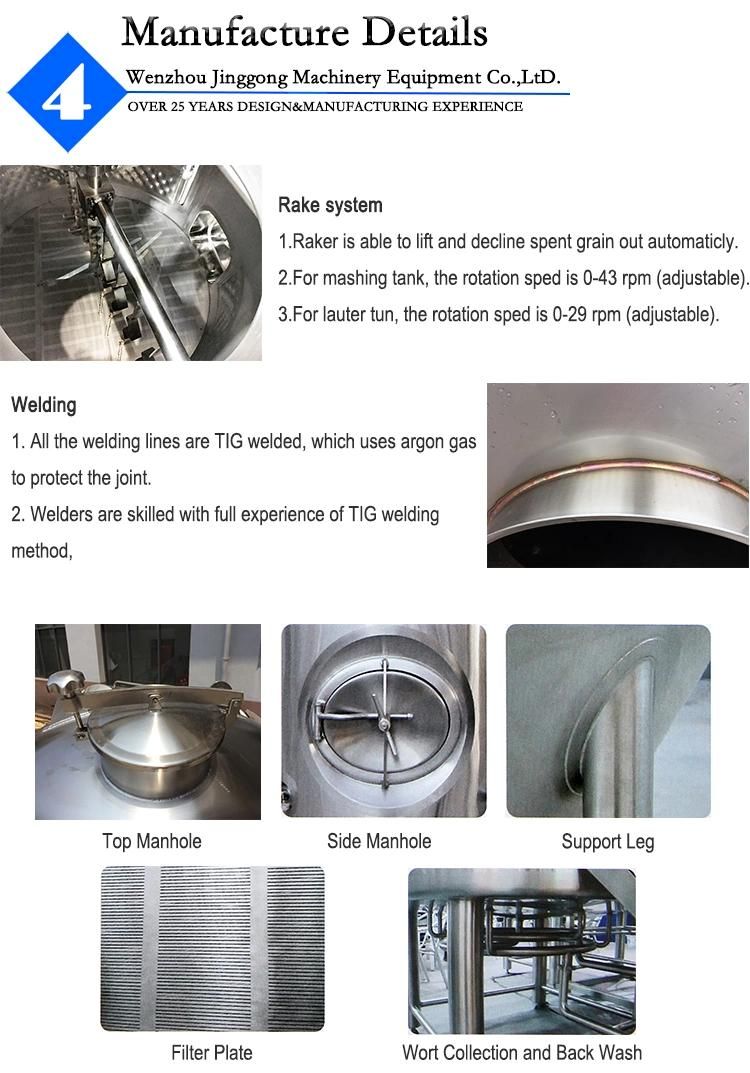

★ Use the biological engineering concept of pure breed asepsis cultivating, no dead space of tank body design, high finish and easy to clean, a very reliable sterilizing performance, and can through the CIP cleaning to ensure the cleaning and sterilization effect of the entire system.

★ Reasonable control procedure, from the CIP cleaning to the whole process sterilization,cooling and cultivating of wort, inside of tank keeps asepsis air positive voltage 0.5bar, to ensure pure breed cultivating of the wort.

★ The smooth design of pipeline, the pipelines all use the closed path design of close type, to ensure that no dead space when cleaning. The whole system no design of steam leaking, keep the working place and environment high health standards.

Equipment characteristics:

★ Accurate manufacturing process: roughness of the tank inside surface is less than 0.4μm, roughness of the tank outside surface is less than 0.8μm.

★ The structure of heating, cooling is unique, highly efficient heat exchange rate.

★ Cooling: shell Miller board inter-layer alcohol water for indirect cooling.

★ Heating: cone bottom Miller board inter-layer steam for indirect heating.

★ Welding of the system pipelines use the argon welder, gas shielded, to ensure the inner surface smooth of pipeline welding, meet the production requirements of pure breed cultivating, and meet the safety of CIP cleaning.

★ A variety of models, can meet the various needs of users. There are manual control system, semi-automatic control system and fully automatic system control. Also can designed according to the requirements of users.

Project / product show:

We can customize the equipment according to your request!!!

Please feel free to contact with us at your convenience,we will come back to you as soon as possible .

Contact:

Miss.Emily

Tel:+86 13736365975

Fax:0086 577 86610990