Stainless Steel Vacuum Emulsifying Mixer Tank Mixing Tank for Liquid Processing Line

Suzhou Forstec Machinery Co., Ltd.- After-sales Service:Yes,Provided

- Warranty:One Year

- Process:Emulsification

- Power Source:Electric

- Certification:CE, MET, CSA, UL, SA8000, ISO9001, SGS

- Automatic Grade:Automatic

Base Info

- Model NO.:3000L

- Application:Milk, Yogurt, Milk Powder, Cheese

- Customized:Customized

- Tank Layer:Single,Double Jacket

- Usage:Emulsification or Mixing or Storage

- Processing:Mirror Polished

- Shape:Horizontal or Vertical

- Tank Type:Open Top or Sealing

- Operation:Continuous

- Thickness:3mm,4mm

- Insulation Layer:Depend on Customer

- Voltage:Customized

- Weight:900kgs

- Diameter:1800mm

- Connect:CIP Unit or Mixing Tank or Storage Tank

- Power:5.5kw

- Melt Material:Chocolate, Milk,Beverage,Coffee

- Motor Brand:Germany

- Transport Package:Wood Case,Plastic Film

- Specification:3000L

- Trademark:FORSTEC

- Origin:China

- HS Code:8421299090

- Production Capacity:1500sets,Year

Description

1. Characteristics of Stainless Steel Emulsificaition Emulsifying Tank Mixing Tank for Liquid and Solid:

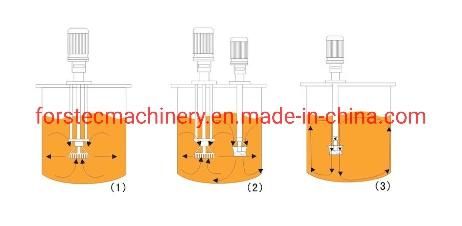

Emulsifying tank functional description:

Usage&Application

Stainless steel stirred tank widely used in pharmaceutical, chemical, food, beverage, water treatment, brewing, ink, oil, printing and dyeing, environmental protection, oil, alcohol, hospitals and other industries, various types of liquid filtration, rough filtration, fine filtration, clarification ideal equipment purification treatment.

Stainless steel mixing tank is my company's own development of new products, with no leakage, fully enclosed, corrosion-resistant, energy-saving features. Due to its non-contact torque transmission to replace the static seal dynamic seal, to solve the other shaft seal can not overcome the problem of leakage, the entire media and agitation in sterile health status to operate, pharmaceutical, fine chemicals, cosmetics and biological engineering industry ideal replacement products.

Suitable material under a certain pressure mechanical stirring flammable, explosive, toxic, odor and other dissolved materials, sterilization, fermentation process takes a long time (over 24 hours) constant moving equipment. More suitable for biological engineering in the production process does not allow any trace leaks and contaminated equipment.

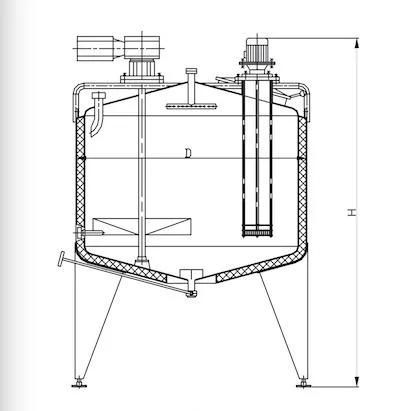

Inside details for Stainless Steel Emulsificaition Emulsifying Tank Mixing Tank for Liquid and Solid:

Drawings:

Detailed Parameters for this Stainless Steel Emulsificaition Emulsifying Tank Mixing Tank for Liquid and Solid:

Common rotation speed 35,43,60 ; stepless speed reducer or dual-speed reducer are also available

Usage for this Stainless Steel Emulsificaition Emulsifying Tank Mixing Tank for Liquid and Solid:

Shipment into container:

Our Products Certificate:

FAQ:

1.How long can I receive your reply after I send my inquiry?

We will reply you within 12 hours on workday.

2.Are you a manufacturer or a commercial company?

We are a manufacturer, and we have a foreign trade department, we market our own products.

3.What products can you provide?

We mainly produce beverage production machinery and equipment.

4.What are the application fields of your products?

Our products are mainly used by beverage factories or individuals who want to run a milk production plant.

5.Can you provide custom products?

Yes, custom products are our main products. We can develop and manufacture products according to customer's drawing or sample. Saving customer's time on finding corollary equipment.

6.How's your production capacity?

Our annual output is about 50,000 sets.

7.How many employees do you have?

We have over 30 employees, including several technicians and engineers.

8.How do you ensure your product quality?

We conduct inspections in every production procedure, and for finished products, we will take 100% inspection depend on international standards according to customer's requirements.

9.Payment?

We will confirm the payment with you when quoting, like FOB, CIF, CNF or others.

In batch production, we accept 30% deposit, balance against the copy of B/L.

T/T is the main payment, and L/C is acceptable as well.

10.What's your delivery method?

We commonly use sea transportation, using container to deliver the goods through Shanghai Port.

11.Where do you mainly export your products?

Our products are mainly exported to Mexico, Saudi Arabia, India, Algeria, Dubai, Congo, African countries, etc.