Automatic China Datong Bread Crumbs Processing Extruder Making Machine Production Line ...

Jinan Datong Machinery Co., Ltd.- Warranty:1 Year

- Certification:CE, ISO9001

- Power Source:Electric

- Automatic Grade:Automatic

- Application:Ice Cream, Chocolate

- Customized:Customized

Base Info

- Model NO.:SLG65-III

- Product Name:Good Quality Bread Crumb Processing Extruder

- Material:Stainless Steel

- Stainless Steel Material:304

- Electric Parts:LG, FUJI, Omron etc

- Raw Material:Wheatflour

- Manufacture:Jinan Datong

- Motor Brand:Siemens China Brand

- Inverter:Delta and China Brand

- Transport Package:Woodcase

- Specification:CE ISO BV SGS

- Trademark:Jinan Datong Machinery Company

- Origin:Jinan

- HS Code:8438800000

- Production Capacity:100-150kg,H

Description

Basic Info.

Model NO. SLG65-III Product Name Good Quality Bread Crumb Processing Extruder Material Stainless Steel Stainless Steel Material 304 Electric Parts LG, FUJI, Omron etc Raw Material Wheatflour Manufacture Jinan Datong Motor Brand Siemens China Brand Inverter Delta and China Brand Transport Package Woodcase Specification CE ISO BV SGS Trademark Jinan Datong Machinery Company Origin Jinan HS Code 8438800000 Production Capacity 100-150kg/HProduct Description

1. Descriptiom:The bread crumbs processing line developed by our company. Breadcrumb is mainly used for beefsteak and drumstick as frying dressing .The long and sliver-shaped breadcrumbs are of porous structure inside .After frying ,the crumbs become straight up bit by bit.They are not only puffed and nice in appearance but also crisp and delicate in taste.Breadcrumbs processing line is specially designed and development according to market demand .The whole line can be finished from the raw material ,extrusion ,drying to finished products automatically.

a. Raw Materials:

This production line adopts cereals flour ,corn, wheat, rice, oat, soy, sesame, walnut, black rice etc.

b. Products:

This line can be used to produce baby food,baby rice, sesame paste,FBF,CSB and samaposha , walnut paste-type products,etc

c. Capacity:

120-150kg/h,160-240kg/h, 300-500kg/h.

d. Flow chart:

1. Flour Mixing 2. Screw Conveyor 3.Extruder 4.Pulling and Cutting machine 5.Hoister 6. Crumbs forming machine 7.Vibrating machine 8.Air Conveyor 9.Dryer 10.Sifter

e. Voltage:

In China: Three phases: 380V/50Hz, Single phase: 220V/50Hz. We can make it according to customers' Local voltage according to different countries.

f. Machines Materials

All the machines are made by stainless steel, this line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function

g. Technical Parameters

| Model | Installed Capacity | Actual Consumption | Main Power | Throughput | Dimension |

| SLG65 | 34kw | 28kw | 22kw | 120-150kg/h | 2400*1200*1800 |

| SLG70 | 42kw | 30kw | 30kw | 160-200kg/h | 2600*1200*1800 |

| SLG85 | 92kw | 75kw | 75kw | 400-500kg/h | 4500*1600*2000 |

| SLG90 | 135kw | 91kw | 75kw | 600-900kg/h | 4500*2000*2000 |

| SLG100 | 55kw | 30kw | 38kw | 80-100kg/h | 3200*1500*2000 |

a. The screws are made by alloy steel (38CrMoAL) and special craft by nitriding process, The HRC hardness is around 60---62, it has good self-cleaning ability and does not need to discharge or clean the barrel and screw, when roasting or replacing of materials.

b. The extrusion barrel is constructed of carbon steel, is made by #45 steel, stainless steel coating.

c. The gearbox has automatic lubrication function, with extends gear life.

d. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

e. SIEMENS(CHINA) brands electronic parts used in the controller box, make sure the extrusion process perfect.

f. Main Motor from SIEMENS(CHINA), ensure its powerful extrusion and excellent performance.

Our Services:

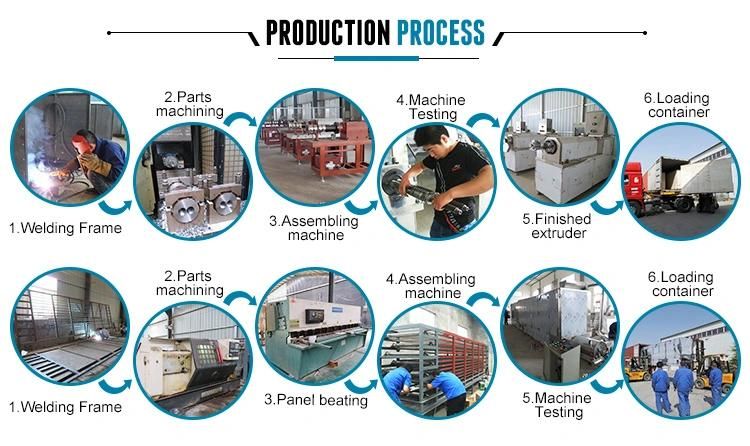

1. In the processing of production, our professional technical engineers inspect the processing to ensure the quality of products

2. Every machine must be tested before delivery for 8 hours , all of them are absolutely qualified.

3. 18 months guarantee of the whole machine.

4. Main parts(excluding the consumables) shall be changed free of charge if there is any problem

during the warranty period.

5. Lifetime maintenance free of charge.

6. We will provide the consumable parts at an agency price when you need replacement.

7. Machine has been adjusted before delivery.

8. Our staff can be sent to your company to install or adjust if necessary

Packaging and shipping:

Every machine is packed with great care and tough material. It is packed with cling films first and then film bags. At last, it is packed with wooden case which is reinforced with the iron bar on the top and bottomWith this kind machine, all our laser machine can protect well during long trip by sea or by train.We can transport machine by boat or by training, according to your requirement.

FAQ:

1. How about the documents after shipment?

After shipment, we'll send all original documents to you by DHL/TNT, including Packing List, Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

For standard machines, it would be20-30 days; For non-standard machines and customized machines according to client's specific requirements, it would be 30-45 days.

3. Do You Arrange Shipment For The Machines?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

4. How is the packing?

Water-proof plastic film package with foam protection in each corner Solid Seaworthy Wood Box Package with Steel BeltSave space as much as possible for container loading .