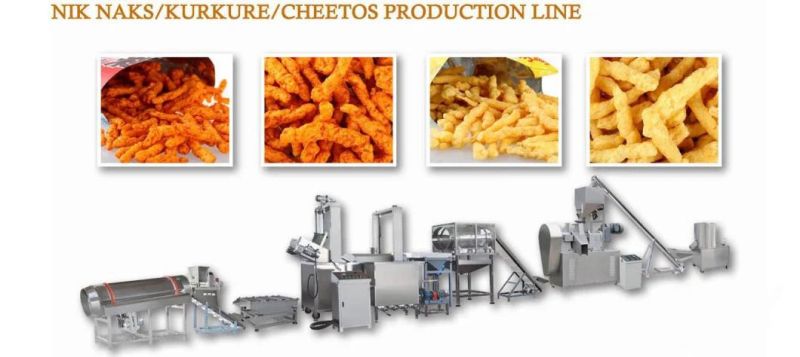

Cheetos Kurkure Niknak Processing Line Cheetos Food Production Equipment

Shandong Nolen Machinery Co., Ltd.- Certification:CE, UL, ISO9001

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Ice Cream, Candy, Chocolate, Popcorn, Chips, Biscuit, Donut

- Customized:Customized

Base Info

- Model NO.:KS76(Toasted)

- Machine Material:Stainless Steel

- Warranty:1year

- Delivery Time:15-30days

- Motor:Siemens,ABB or Chinese Brand

- Raw Material:Rice Flour,Corn Flour,Soyabean Flour

- Energy:Electric,Diesel,Gas

- After Sale:24hours

- Control:PLC,Menu

- Function:Multifunctioal

- Package:Wooden Case

- Transport Package:Wooden Case

- Specification:18000*1200*2200mm

- Trademark:KS

- Origin:Shandong, China

- HS Code:8438800000

- Production Capacity:30 Set,Month

Description

Basic Info.

Model NO. KS76(Toasted) Machine Material Stainless Steel Warranty 1year Delivery Time 15-30days Motor Siemens,ABB or Chinese Brand Raw Material Rice Flour,Corn Flour,Soyabean Flour Energy Electric/Diesel/Gas After Sale 24hours Control PLC/Menu Function Multifunctioal Package Wooden Case Transport Package Wooden Case Specification 18000*1200*2200mm Trademark KS Origin Shandong, China HS Code 8438800000 Production Capacity 30 Set/MonthProduct Description

Cheetos Kurkure Niknak Processing Line Cheetos Food Production EquipmentDescriptionKurkure are extruded snacks, very crunchy and great in taste. Kurkure are made by extrusion process. The Kurkure corn meal is moisturized in the flour mixer with water and fed to the Rotary die Extruder. In the extruder, due to excess heat and pressure from the screws the meal gets heated and the moisture content gets reduced. The meal passes through the die and gets cut by the cutting knifes into required lengths. The Kurkure are fried in cooking oil and then cooled before flavoring. Seasoning is sprayed on the Kurkure to improve their taste.

Processing LineFlour Mixer → Screw Conveyer → Rotary Head Extruder → Hoister → Separate Drum → Vibrate Feeder → Continuous Fryer → Vibrate de-oil Machine → Flavoring/Seasoning Machine

This processing line from feeding, extruding, shaping ,cutting , oil spraying to finished products are done once time automatically. Visible auto-temperature controlling system, make the temperature-controlling to be more direct-viewing, parameter to be more precise.

Specifications: The screws are made by ally steel and special craft, the screw life is longer, uses building block system structure, may combine willfully.

Specifications: The screws are made by ally steel and special craft, the screw life is longer, uses building block system structure, may combine willfully.The forced lubrication system can guarantee equipment transmission longer life.

1. Raw materials: Corn Grits

2. Products: Kurkure/Cheetos/Niknak with different taste

3. Capacity: 120-140 KG/H, 180-240 KG/H

4. Flow Chart: Mixing-Extrusion-Separating-Frying/Baking- Flavoring

5. Voltage: Three phases: 380V/50HZ, Single phase: 220V/50HZ, we can make it according to customers' local voltage of different countries.

6. Machines Materials: All the machines are made by food grade stainless steel.

This is the core part of the whole baked kurkure making machine. Its main function is to extrude,rub and turn the mixer of raw material and water into the basic shapes. This part can fry the kurkureand make the products crispy. The machine can control the temperature, easy to operate and clean. The roller is full set stainless steel. With the rolling of the drum, the flavor and oil can be mixed with Kurkure evenly. Technical parameters

| Model | KS-76(dry) | KS-76(roasted) |

| Installed Power | 40-65KW | 30-45KW |

| Power Consumption | 50KW | 70KW |

| Max. Output | 100-150kg/h | 100-150kg/h |

| Dimension | 18000*1200*2500mm | 18000*1200*2200mm |

Packing & Shipping:

Each machine is carefully packed. It is packed with cling films first and then film bags. At last, it is packed with wooden case which is reinforced with the iron bar on the top and bottom. With this kind machine, all our laser machine can protect well during long trip by sea or by train.

Our factory:

Our customers:

Our Certificates:

About us & more details:

| MOQ | 1 set |

| Supply Ability | 20 sets per Month |

| Shipping port | Qingdao port, Shandong, China |

| Packing details | Fumigation-free wooden case outside, stretch film inner |

| Relevant spare parts | free, delivery with processing line |

| Guarantee | Within 12 months |

| Oversea service | Provide installation and commissioning after machine arrived your factory |

| Payment terms | 30% is paid by T/T as the down payment, 70% is paid by T/T orL/C before shipment. |

| Delivery time | 30 days after receipt the deposit |

| Pre-shipment | When it finished, we will invite you to our company to inspect machines, when no problem, we will arrange the shipment |

FAQ:

1. How about the documents after shipment?

After shipment, we'll send all original documents to you by DHL/TNT, including Packing List, Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

For standard machines, it would be20-30 days; For non-standard machines and customized machines according to client's specific requirements, it would be 30-45 days.

3. Do You Arrange Shipment For The Machines?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

4. How is the packing?

Water-proof plastic film package with foam protection in each corner Solid Seaworthy Wood Box Package with Steel BeltSave space as much as possible for container loading