Corn Rice Puff Snack Extruder Food Making Machine

Shandong Nolen Machinery Co., Ltd.- Certification:CE, ISO9001

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Ice Cream, Candy, Chocolate, Popcorn, Chips, Biscuit, Donut

- Customized:Customized

Base Info

- Model NO.:KS-65,70,85,90

- Transport Package:Wooden Case

- Specification:30*3*4.5m

- Trademark:KS

- Origin:Shandong China

- HS Code:8438800000

- Production Capacity:100-200kg,H, 200-300kg,H, 500kg,H

Description

Basic Info.

Model NO. KS-65/70/85/90 Transport Package Wooden Case Specification 30*3*4.5m Trademark KS Origin Shandong China HS Code 8438800000 Production Capacity 100-200kg/H, 200-300kg/H, 500kg/HProduct Description

Corn Rice Puff Snack Food Making MachineCore filling corn rice puff snack food making machine1.Product description :

Corn puff snack food machine adopt corn, rice, wheat, oat, barley etc as ingredients to make puffed snack. Through frication of screw and barrel, the grains are cooked in the extruder. The product shape is determined by a combination of the die aperture, including ball, tube, stick, ring, fruit loop, star, wheel and flower etc.

Model | Installed power | Real power | Output | Dimension |

KS65 | 140kw | 90kw | 150kg/h | 39000x1200x2200mm |

KS70 | 160kw | 120kw | 200kg/h | 41000x1500x2200mm |

KS85 | 190kw | 140kw | 300kg/h | 43000x3500x4300mm |

a. Raw materials:

adopts corn flour, rice flour, wheat flour, and other grain flour as raw materials.

b. Products:

This line can be used to produce corn flakes, breakfast cereals, snacks, cereals by adjusting the moulds from extruder

c. Capacity: 100-150kg/h, 150-260kg/h, 250-500kg/h, 500-800kg/h

d. Flow chart:

mixer→screw conveyer→KS 65twin-screw extruder→hoister(air conveyer)→3-layer 5 meter roasting oven→single drum flavoring line→cooling machine→packing machine(optional)

mixer→screw conveyer→KS70 twin-screw extruder→hoister(air conveyer)→5-layer 5 meter roasting oven→double-drum flavoring line→cooling machine→packing machine(optional)

e. Voltage in China:

Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it

according to customers'Local voltage according to different countries.

f. Machines Materials:

stainless steel

g. features:

(1).The extruding crispy snacks food making lines has the advantage of rational design, high automatic degree and accuracy control.

(2).The main body material is stainless steel, which is easy to be cleaned.

(3).The screws material is 38CrMnAl, which is wear-resisting.

(4).Our project is turn-key. We will send our engineer to your factory, install and debug the

equipments, and train your operators.

(5).The temperature and rotating speed can be controlled and adjusted.

Twin screw extruder

Double screw extruder

| Model | KS95 | KS90 | KS85 | KS70-1 | KS70 | KS65 |

| Installed Power | 100.7kw | 82.5kw | 92kw | 61.5kw | 46.5kw | 35kw |

| Main Motor Power | 90kw | 75kw | 75kw | 45kw | 30kw | 22kw |

| Capacity | 1500-2000kg/h | 800-1200kg/h | 400-500kg/h | 200-260kg/h | 200-260kg/h | 100-150kg/h |

| Dimension | 4.9×1.2× 2.7m | 4.7×1.2×2.5m | 3.9×1.2×1.8m | 2.8×1.0×1.9m | 2.8×1.0×1.9m | 2.7×0.9×1.8m |

Multi layer dryer

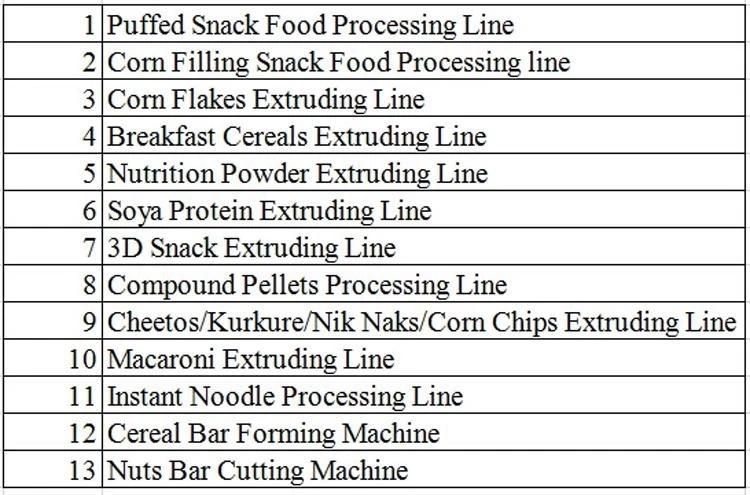

Prouduction lines we have

Compatative Advantages

1. Guaranty: One Year.

2. One set of consumable accessories will be provided with the machine.

3. Any question, you can mail/call us at any time. And our most experienced engineers are assigned to give consulting service, and always available for dispatching abroad.

4. All spare parts are always available for delivery.

5. Manual is in English.

6. Minimum order: 1 set

7. Prompt Delivery: 15-20 working days after receiving deposit

8. Installation: sending one technician to the customer's factory for installation and training.

9. Packaging: firstly packing with plastic inner side, then strengthening with wooden case outside.

Our Company

Keysong was founded in 2013. Specializing in producing food machines for more than 6 years. Since its inception, it is specializing in the manufacture, research, development, sales and after-sales of food extrusion machine, puffed food production line, fruit and vegetable washing and drying processing line. Puffed food equipment: food extruder, twin screw extruder, single screw extruder, breakfast cereals/corn flakes production line, fried and baked snacks production line, pet food production line, fish feed production line, textures soya protein production line, modified starch production line, bread crumb production line, laboratory twin screw extruder, nutritional rice production line, etc.

Vegetable washing and drying machinery: brush washing peeler, fully automatic roller cleaning and peeling machine, vegetable and fruit slicer, blanching and pasteurization equipment, vegetable and fruit drying machine, tunnel type dryer.

Customer

Packing and shipping

Contact us

Sales manager: Christine

Mobile: +86 18560057392

Jinan Keysong Machinery Co.,ltd