Puffed Core Filling Snack Food Extruder Making Machine with 5 Star Service Good Quality

Shandong Nolen Machinery Co., Ltd.- Certification:CE, ISO9001

- Power Source:Electric

- Process:Mild Processing

- Automatic Grade:Automatic

- Application:Ice Cream, Candy, Chocolate, Popcorn, Chips, Biscuit, Donut

- Customized:Customized

Base Info

- Model NO.:KS-65,70,85,90

- Nachine Material:Stainless Steel

- Output:100-150kg,H,200-00kg,H,500-800kg,H

- Warranty:1 Year

- Total Weight:1000kg

- Main Motor:Simens(China)

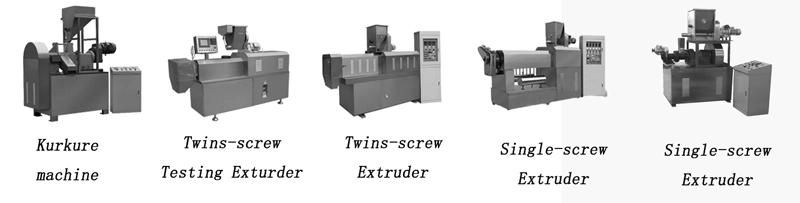

- Type:Twin Screw Extruder

- Transport Package:Wooden Case

- Specification:30*3*4.5m

- Trademark:KS

- Origin:Shandong China

- HS Code:8438800000

- Production Capacity:100-200kg,H, 200-300kg,H, 500kg,H

Description

Basic Info.

Model NO. KS-65/70/85/90 Nachine Material Stainless Steel Output 100-150kg/H,200-00kg/H,,500-800kg/H Warranty 1 Year Total Weight 1000kg Main Motor Simens(China) Type Twin Screw Extruder Transport Package Wooden Case Specification 30*3*4.5m Trademark KS Origin Shandong China HS Code 8438800000 Production Capacity 100-200kg/H, 200-300kg/H, 500kg/HProduct Description

Puffed Core Filling Snack Food Extruder Making Machine With 5 Star Service Good Quality Core filling snack food processing line

Core filling snack food processing line1.Product description :

It is mainly made from corn powder. It is a new choice for your breakfast after mixing with milk. Designed as a kind of breakfast cereal, it is crunchy taste and water resisting property make you have something in mouth for chewing, but not hard. Our company has three types production lines by capacity 150kg/hr, 240kg/hr and 500kg/hr

a. Raw materials:

adopts corn flour as raw materials

b. Products:

This line can be used to produce corn flakes, breakfast cereals, snacks, cereals by adjusting the moulds from extruder

c. Capacity: 150kg/h, 260kg/h for corn flakes; 150kg/h, 260kg/h and 500kg/h for breakfast cereal.

d. Flow chart:

Mixing system---Extrusion system---Cooling system---Flaking system---Drying system---Toasted system---Sugar Spraying system---Drying system---Packing system

e. Voltage in China:

Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers'Local voltage according to different countries.

f. Machines Materials:

All the machines are made by stainless steel at food grade, this line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function.

g. Technical Parameters:

Model | Installed power | Real power | Output | Dimension |

KS65 | 140kw | 90kw | 150kg/h | 39000x1200x2200mm |

KS70 | 160kw | 120kw | 200kg/h | 41000x1500x2200mm |

KS85 | 190kw | 140kw | 300kg/h | 43000x3500x4300mm |

Acessories and Cerresponding Condition for the Processing Line

our aoutomatic multifuctional fish feed pellet processing line support the CE Certification 304 Stainless Steel quality and one year warranty ,Germany import eletronic components

siemens and and siements motor / 380V /50Hz three phases or single phase220V / 50Hz

2.Feature

(1).The extruding crispy snacks food making lines has the advantage of rational design, high automatic degree and accuracy control.

(2).The main body material is stainless steel, which is easy to be cleaned.

(3).The screws material is 38CrMnAl, which is wear-resisting.

(4).Our project is turn-key. We will send our engineer to your factory, install and debug the

equipments, and train your operators.

(5).The temperature and rotating speed can be controlled and adjusted.

3.Our Goal

1)Our goal is to make sure you are a happy customer and pleasant business with us.

2)If you are not satisfied with your purchase in any way, Please give us the opportunity to resolve any problem. We understand the concerns and frustrations you might have, and will try our best to resolve the issues.

3)If you're not pleased with your purchase, we'll be happy to make an exchange or refund in delivery days.

4)For any exchange or refund, we need the product must be in its original condition, including the box, and all the accessories. buyers are responsible for the returning shipping cost.

4. Package and Shipping:

5. FAQ And Service:

A. Finished time

The production line will be finished in 30-40 days after confirmation.

B. Payment Term

30% is paid by T/T as the down payment, 70% is paid by T/T or L/C before shipment.

C. Delivery Time

When the machines are finished, we will invite you to our factory for testing machine.

Our Services

* Related machines's technical parameter will be supplied to customer.

* According to customer's factory size, factory layout can be provided in advance.

* According to customer's material cost, general formulation can be prepared well.

* Special machine can be supplied as customer's request.

* Professional Advice about Market, machines, processing , materials, packing can be supplied

* Suggesting professional ship agent or helping book ship as customer request.