Core Filling Snack Chocolate Candy Peanut Bar Jam Center Food Making Machine

Shandong Nolen Machinery Co., Ltd.- Certification:CE, ISO9001

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Ice Cream, Candy, Chocolate, Popcorn, Chips, Biscuit, Donut, Snack

- Customized:Customized

Base Info

- Model NO.:ks 70

- Nachine Material:Stainless Steel

- Output:100-150kg,H,200-00kg,H,500-800kg,H

- Warranty:1 Year

- Total Weight:1000kg

- Main Motor:Simens(China)

- Type:Twin Screw Extruder

- Transport Package:Wooden Case

- Specification:30*3*4.5m

- Trademark:KS

- Origin:Shandong China

- HS Code:8438800000

- Production Capacity:100-200kg,H, 200-300kg,H, 500kg,H

Description

KS65

KS70

KS85

four mixing system

Detailed pictures of brush roller washing and peeling machine

Double screw extruder

1. frequency speed controlling with high automation and stable per-formation.

2. The screws material: alloy steel and special craft characterized by durable usage, high pressure and long life. Adopting the building block structure and combining willingly according to the different demand.

3. with forced lubrication system;

4. Auto-temperature control system.

5. Self-cleaning without disassembling.

Core filler

Shaping and cutting machine

belt drying oven

Our company

About Jinan Keysong Machinery

Jinan Keysong Machinery Co., Ltd was founded in 2013, it is located at Jiyang Economic Development Zone. Since its inception, it is specializing in the manufacture, research, development, sales and after-sales of food extrusion machine, puffed food production line, fruit and vegetable washing and drying processing line.

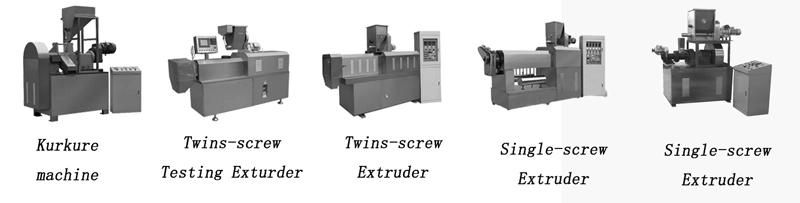

Puffed food equipment: food extruder, twin screw extruder, single screw extruder, breakfast cereals/corn flakes production line, fried and baked snacks production line, pet food production line, fish feed production line, textures soya protein production line, modified starch production line, bread crumb production line, laboratory twin screw extruder, nutritional rice production line, etc.

Vegetable washing and drying machinery: brush washing peeler, fully automatic roller cleaning and peeling machine, vegetable and fruit slicer, blanching and pasteurization equipment, vegetable and fruit drying machine, tunnel type dryer.

Our service

1. OEM & ODM

2. One year guarantee and life-time maintenance service.

3. Consultation service before, during, and after sales.

4. Provide factory layout according to your factory size in advance;

5. Provide the basic formula;

6. Debugging of machines until all are functional.

7. Training the customers how to operate and maintain the machines correctly.

8. Offer new product techniques and recipes timely.

Packing and delivery

Before packing, we will test and debuge the machine.

• packing with stretch plastic film if deliver with whole containcer( or according to customer's request)

.

• Only plastic film nude packing with wooden pallet.

• We can supply fumigation package and certificate.

• Shipping, train, express or upon clients' demands.

FAQ

1) Are you a factory?

Yes, we have committed to the puff food machine and vegetable and fruit manufacturing for 9 years.

2) What's the delivery time?

For our standard machines(voltage 380v/50hz), we can ship within 7 working days. For customized processing line, around 20 working days.

3) Can you offer machine installation and training service?

We have 10 senior engineers with more than 8 years food machine production experience. After shipment, we will arrange our experienced engineers to visit customer's factory for machine installation and training. After installation, our after sale service team and engineer could solve problems with video chat or phone.

4) How about the spare parts?

Provide necessary spare parts on delivery within warranty time. Provide spare parts with factory price out of warranty period.

5)what is your warranty period?2 years.