Corn Curls Cheetos Kurkure Nik Naks Making Machinery

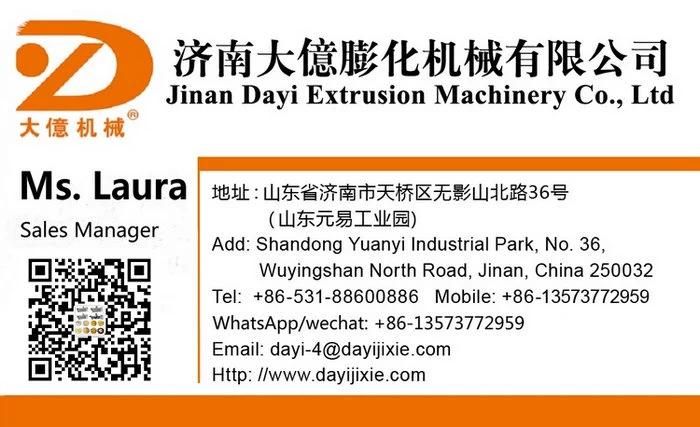

Jinan Dayi Extrusion Machinery Co., Ltd.- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Customized:Customized

- Motor:ABB,Siemens

- Cover:Ss201,304

Base Info

- Model NO.:DLG

- Product Name:Cheetos Machine

- Transport Package:Wooden Box

- Specification:CE ISO9001

- Trademark:DAYI

- Origin:China

- HS Code:84388000

- Production Capacity:20 Sets,Month

Description

Basic Info.

Model NO. DLG Product Name Cheetos Machine Transport Package Wooden Box Specification CE ISO9001 Trademark DAYI Origin China HS Code 84388000 Production Capacity 20 Sets/MonthProduct Description

Corn Curls Cheetos Kurkure Nik Naks Making Machinery

Description

Fried cheetos kurkure niknak processing line

Brief decription:

This Fried cheetos kurkure niknak processing line can use corn grits instead of the powder material to produce the irregular stick sanack. This extruder is specially designed with one screw only for such cheetos, kurkure, or niknak. After shaped from extruder, the products will be sent into the rotary sifter to take down extra grits sticky on the surface. The waste grits can be collected and used again as raw materials. So this processing line can lower down the production cost. After fried and flavored, the final cheetos or kurkure will be more tasty and crispy.

Production Flow:

Flour Mixer → Cheetos Extruder → Conveyor → Rotary Sifter → Elevator → Fryer → Vibrating De-Oiler → Flavoring Line → Cooling Conveyor

Our Company

Established in 1996, Jinan Dayi Extrusion Machinery Co., Ltd has been the professional manufacturer and the model company for advanced and high efficient extrusion food machinery in this field.

DAYI Company congregates an expert team with twenty-year experiences in this extrusion machine industry, not only working hard to constantly researching extrusion technology, but also exploring food processes in order to benefit our clients producing creative food.

After years of research and development, our single and double screw extrusion technique has been widely applied to produce the following products: puffed snacks, core-filling snacks, breakfast cereal / corn flakes, 2d/3d pellet, textured soya protein/fibre protein/vegetarian meat, doritos/ tortilla chips, cheetos/niknak/kurkure, ball/butterfly popcorn, fried flour food, bread crumb, nutritional rice/ artificial rice, nutritional powder/baby food powder, and pet food, etc.

More than twenty production lines with different functions and capacities can be chosen. And we can also provide customized service for special requirements.

Related snacks food process line

Puff snacks/ core filling snacks process line

Breakfast cereals/ corn flakes process line

Fried wheat flour snacks food process line

2D/3D snack pellet process line

Soya protein process line

Bread crumbs process line

Nutritional rice process line

Nutritional powder/ baby food process line

Dorito/ tortilla chips process line

Cheetos/kurkure/niknak process line

Pet food process line

etc