Hot Sale Wheat Starch Gluten Production Line

Shanghai Genyond Technology Co., Ltd.- Type:Pressing Machines

- Application:Starch

- Voltage:380V

- Appearance:Vertical

- Press Materials:Corn

- Press Series:Second

Base Info

- Model NO.:GYWS-1

- Condition:New

- Customized:Customized

- Material:Stainless Steel

- Turn-Key Project:Yes

- Capacity:as Customer Request

- Brand:Genyond

- Transport Package:According to Different Inquired

- Specification:industry corn starch processing line

- Trademark:Genyond

- Origin:China

- HS Code:84381000

- Production Capacity:10set ,Month

Description

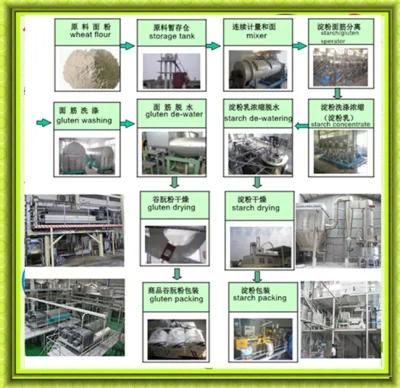

A)Gluten and Starch Separation Section

In this section, we separate the starch and protein first before the gluten forming to keep the liveness of gluten so as to keep the gluten with high water absorption, low ash, low fat characteristic, and any more water can be saved by this way With advanced AUTO-CONTROL SYSTEM supplied by myande, the whole production line will be operated smoothly.

Myande provide wheat gluten and starch separation engineering services with capacity ranging from 8t/h flour to 20t/h flour.

B)Gluten Dewatering and Drying Section

Myande have developed the process with high efficiency, more economical and reliable ability to make the gluten powder achieve the effect with high water absorption, more fineness and the color looks more natural, quality will be uniformly. The process have broken out the traditional limitations in dewatering, drying, crushing and mixing powder of gluten. With advanced AUTO-CONTROL SYSTEM supplied by myande, the whole production line will be operated smoothly.

Myande provide the production line of wheat gluten, starch separation and dewatering, drying, crushing and mix powder engineering services with capacity ranging from 0.8t/h to 2.5t/h.

C)Starch Dewatering and Drying Section

Myande have developed the process with high efficiency, more economical and reliable ability to make the wheat starch achieve the effect with high water absorption, more fineness and the color looks more natural, quality will be uniformly. The process have broken out the traditional limitations in dewatering, drying, crushing and mixing. With advanced AUTO-CONTROL SYSTEM supplied by myande, the whole production line will be operated smoothly.

Myande provide wheat A-starch dewatering, drying, crushing and mix powder engineering services with capacity ranging from 3t/h to 15t/h.

Myande provide wheat B-starch dewatering, drying, crushing and mix powder engineering services with capacity ranging from 0.8t/h to 3t/h.

2. Engineering Capacity

A)Providing complete wheat starch processing equipment line with capacity ranging from 60000 to 1200000 tons per year, and complete wheat gluten processing equipment line with capacity ranging from 5000 to 20000 tons per year

B) Meticulous 3D design creates direct, accurate and clear presentation of every detail of the project design.

C)Experienced professionals provide first-class process and equipment designs.

D)Advanced automatic control system ensures high reliability of the whole production line.

3. After-sales Service Provided

Before sale, we can help the buyers planning the general plan.

Generally, we guarantee all equipments are completely new and unused, and under normal operation conditions the warranty period would be 12 months after installation or 18 months from the date of shipments whichever comes first.

Our equipment would be shipped in containers. Equipments too large for containerized shipment would be covered and protected from sea water damage.

We can send experienced and qualified engineers (electrical engineer and mechanical engineer) to the Buyer's site for supervision of equipment installation and commissioning. And after the plant had been successfully commissioned, our engineer will stay to train the buyer's plant personnel in process operations and equipment maintenance by buyer's request.