Automatic Wheat Puffing Snack Bar Production Line Breakfast Cereal Bar Snack Process ...

Shandong Loyal Intelligent Machinery Co., Ltd.- After-sales Service:12 Months

- Warranty:12 Months

- Certification:CE, ISO9001

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

Base Info

- Model NO.:LY65LY70LY75LY85LY95

- Application:Grain Bar

- Customized:Customized

- Material:Stainless Steel,Carbon Steel

- Main Machine:Twin Screw Extruder

- Function:Fully Automatic

- Installation:Engineer Guide

- Capacity:100-150g,H 200-250kg,H 300-500kg,H 300-500kg,H 800

- Transport Package:Film&Wooden Box Packing

- Specification:2.5*1.2*1.5m

- Origin:Jinan, China

- HS Code:8438800000

- Production Capacity:5000 Sets,Year

Description

Basic Info.

Model NO. LY65LY70LY75LY85LY95 Application Grain Bar Customized Customized Material Stainless Steel/Carbon Steel Main Machine Twin Screw Extruder Function Fully Automatic Installation Engineer Guide Capacity 100-150g/H 200-250kg/H 300-500kg/H 300-500kg/H 800 Transport Package Film&Wooden Box Packing Specification 2.5*1.2*1.5m Origin Jinan, China HS Code 8438800000 Production Capacity 5000 Sets/YearProduct Description

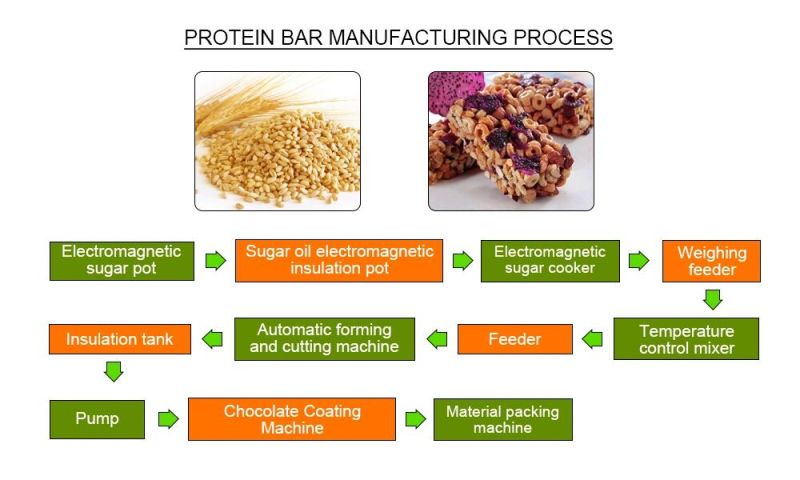

Automatic wheat puffing snack bar Production Line Breakfast Cereal Bar Snack Process Machine Nutrition bar production line is made with foreign advanced technology according to the candy factories's needs. Nutrition bar processing machine can make creamy candy and grain products with adhesive of melted sugar. Nutrition bar making machine is consist of batch rollor with 6 wheels, flatten machine, cooling conveyer cabinet, forming machine and cooling slifer. The main part of the machine is equiped with frequency control of motor speed. This production line is the ideal equipments of nowdays with the reasonable construction, high output, easy operation and maintance.

Nutrition bar production line is made with foreign advanced technology according to the candy factories's needs. Nutrition bar processing machine can make creamy candy and grain products with adhesive of melted sugar. Nutrition bar making machine is consist of batch rollor with 6 wheels, flatten machine, cooling conveyer cabinet, forming machine and cooling slifer. The main part of the machine is equiped with frequency control of motor speed. This production line is the ideal equipments of nowdays with the reasonable construction, high output, easy operation and maintance.Process Flow of Nutrition Cereal Bar Processing Line

Roaster--Peeling-Cutting Machine--Sugar Cooking Machine--Mixer Machine--Cutting Forming Machine

he rice, peanuts and nuts are put into the oven for roasting and then into the peeling cutter. The sugar is cooked in the sugar boiler. The peeled and cut raw materials and the cooked sugar go into the mixer for blending. Then it goes into the forming machine, where it can be formed into different shapes of nutritional bars depending on the mould.

he rice, peanuts and nuts are put into the oven for roasting and then into the peeling cutter. The sugar is cooked in the sugar boiler. The peeled and cut raw materials and the cooked sugar go into the mixer for blending. Then it goes into the forming machine, where it can be formed into different shapes of nutritional bars depending on the mould.Functions of Each Section

| No. | Machine | Function |

| 1 | Roaster | Baking of raw materials to cook them |

| 2 | Peeling-Cutting Machine | Some ingredients need to be peeled such as melon seeds and peanuts. Peeling-Cutting Machine can be done efficiently. |

| 3 | Sugar Cooking Machine | The sugar cooking machine the sugar to make the bars delicious and tasty. |

| 4 | Mixer Machine | The peeled and cut raw materials and the cooked sugar go into the mixer for blending. |

| 5 | Cutting Forming Machine | Different moulds to form different shapes of nutrition bars |

Machine Parameters of Nutrition Cereal Bar Processing Line

| Machine Name | Capacity | Dimension |

| 1.Grain puffing machine | 100kg/h | 1320*970*960mm |

| 2.Sugar Cooker | 100L | 1320*970*960mm |

| Sugar Cooker | 200L | 1550*1200*1100mm |

| 3.Mixing Machine | 3-8kg/time | 800*1400*820mm |

| Mixing Machine | 12-20kg/time | 800*1650*1600mm |

| 4.Cereal bar cutting machine /cereal bar press machine | 150-200kg/h | 1880*1110*1160mm |

| 5.Cereal bar packaging machine | 30-200pcs /minute | 3200*600*1000mm |

Finished product live display

1. Frequency conversion speed regulation, paving and leveling, cutting into pieces at one time

1. Frequency conversion speed regulation, paving and leveling, cutting into pieces at one time2. Equipped with multiple leveling structures to make it level and uniform in thickness

3. The size of the block can be adjusted arbitrarily to meet your different needs

4. Automatic cutting, saving time and effort, economical and convenient.

Shipping Pictures

About our companyCompany Profile

About our companyCompany ProfileWe are a professional manufacturer of food machinery and we have been manufacturing nutrition cereal bar processing line for nearly 20 years.

In addition to the Nutrition Cereal Bar snack processing line, we also manufacture lines for deep-fried food, pet feed, modified starch and many more. Each of our lines has basically a variety of moulds, which can be adapted to produce a wide range of food products. We are not satisfied with the status quo but are constantly upgrading and innovating our products, adapting our production plans and designs to the changing needs of the times and keeping up with the pace of progress. Never satisfied with the pursuit of excellence!Customer Visits

Company Honours

Company Honours

Equipment After-sales Service.

Equipment After-sales Service.1. Recipe: The company's after-sales service department can provide free basic recipes or introduce more marketable recipe experts.

2. training: after the installation and commissioning of the equipment can be on-site training of relevant operators, equipment easy to operate.

3. return visit: regular after-sales telephone call back to customers, to help you solve the relevant problems encountered in the use of equipment.

4. maintenance: our company provides quality and inexpensive spare parts to the demand side all year round, and provides equipment upgrades and new product development support, really let you have no worries.

5. Out of warranty maintenance: the company provides free maintenance for equipment damage caused by non-human factors during the warranty period. If the equipment is damaged due to human factors and force majeure, the company will provide maintenance services but charge the relevant fees.