Hydraulic Extruder with Fryer System

Handyware (China) Engineering Co., Ltd.- Certification:CE

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Chips

- Customized:Customized

Base Info

- Model NO.:PR200

- Material:Stainless Steel 304#

- Power:40kw

- Weight:14t

- Electricity Requirement:380V,220V 50Hz,60Hz 3phase

- Capacity:200kg,H

- Control System:PLC & Touch Screen

- Diesel Fuel:45-65kg,H

- Natural Gas:40-70 Cubic Meter Per Hour

- Oil Capacity(in Heat Exchanger & Pipes):1200kg

- Compressed Air Supply:0.4m3,Min 0.5,0.8MPa

- Transport Package:Wooden Case Package

- Specification:17.1*5*4.5

- Trademark:Handyware

- Origin:Foshan

- HS Code:8438800000

- Production Capacity:200kg,H

Description

Basic Info.

Model NO. PR200 Material Stainless Steel 304# Power 40kw Weight 14t Electricity Requirement 380V/220V 50Hz/60Hz 3phase Capacity 200kg/H Control System PLC & Touch Screen Diesel Fuel 45-65kg/H Natural Gas 40-70 Cubic Meter Per Hour Oil Capacity(in Heat Exchanger & Pipes) 1200kg Compressed Air Supply 0.4m3/Min 0.5/0.8MPa Transport Package Wooden Case Package Specification 17.1*5*4.5 Trademark Handyware Origin Foshan HS Code 8438800000 Production Capacity 200kg/HProduct Description

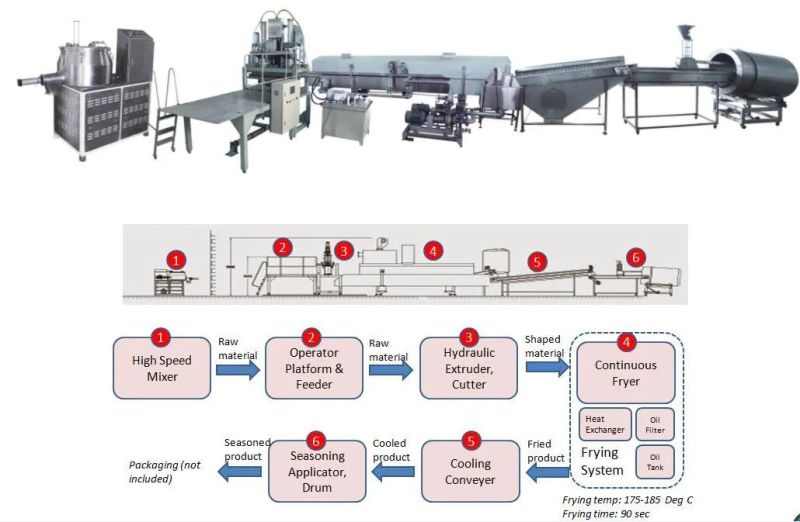

Hydraulic Extruder Processling Line

Technical Information

| Introduction | Hydraulic extrusion to product ring or stick shaped chips |

| Model | PR200 |

| Capacity | 200kgs/hr |

| Dimensions(L*W*H) | 17.1m X 5m X 4.5m |

| Power | 35-40KW |

| Weight | 12-14T |

| Electricity requirement | 380V/220V 50Hz/60Hz 3phase |

| Material | SS304 |

| Compressed air supply | 0.6-0.8Mpa |

| *Diesel fuel | 15-30kg/h |

| *Natural gas | 16-32 cubic meter per hour |

| *LPG | 8-13 cubic meter per hour |

| Frying oil refuel rate | 52kg/h |

| Energy in heat exchanger | 450,000cal/hour |

End product

Customer of Handyware Engineering

Exhibition

Patent Certificate:

Before sale services:

1. Provide initial standard machine configurations.

2.According to the clients' special requirment,offer customized and competitively priced solution. Where necessary,offer customer with options .

3.Help client design the factory and offer professional advice ,provide free drawing for the factory layout.

4.Welcome to visit our factory for machine viewing or trial.

Services during the sales:

1.Provide customer with regular production status update.

2. Invite customer for inspection of machine before delivery.

After sale services:

1.Oversea install of the equipment.

2.Provide the basic food formulation.

3.Operation/Service/Maintenance Manual: Provided in English.

4. We will provide engineers to client's factory for the installation and training . The client is required to provide accomodation,food, round-trip ticket, visa,transportation fee and engineer fee of $80 /day/engineer.

Design of capacity as per needs.