2022 The Latest Model of Milk Yogurt Production and Canning Integrated Production Line

Weishu Machinery Technology (Shanghai) Co., Ltd.- After-sales Service:One Year

- Warranty:One Year

- Process:Thermal Processing

- Power Source:Electric

- Certification:CE, ISO9001

- Automatic Grade:Automatic

Base Info

- Model NO.:WS-FQ-3

- Application:Milk, Yogurt, Milk Powder, Cheese

- Customized:Customized

- Power:30-50kw

- Sterilization Method:High Pressure Hot Water

- Filtering Method:Mechanical Filtration

- Packing:Plastic Bottle&Glass Bottles&Carton

- Transport Package:Export Standard Package

- Specification:300L,H to 3000L,H

- Trademark:WS

- Origin:Shanghai, China(Mainland)

- HS Code:8434200000

- Production Capacity:60set,Year

Description

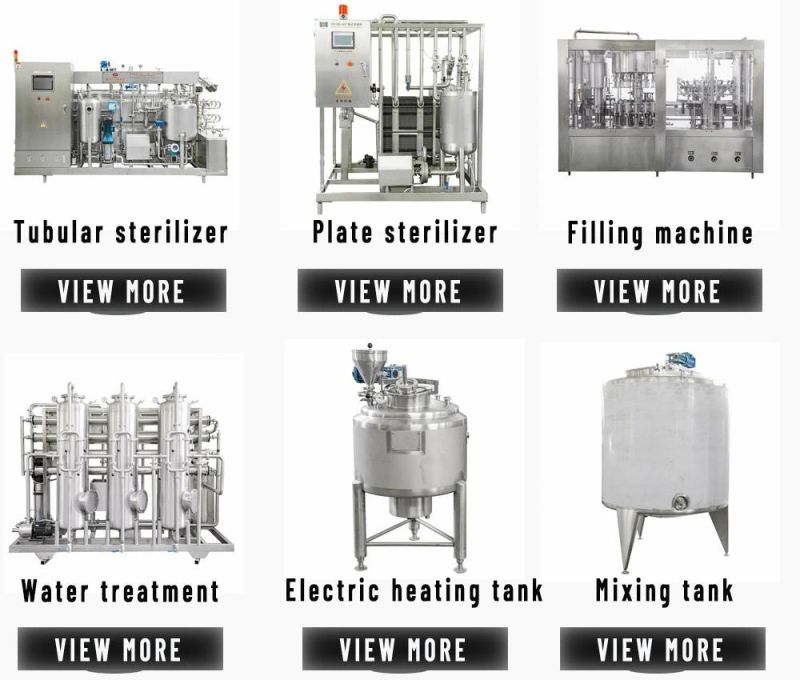

Production line introduction:

After centrifugation, standardization, homogenization, sterilization and cooling, the milk can be directly filled after pasteurization and homogenization without any additives. Due to low temperature sterilization, the beneficial bacteria in milk can be retained, and the nutritional value is particularly high. Moreover, the cost of the equipment is low and the package is simple.

Pasteurized milk is a kind of "low temperature pasteurized milk". The harmful microorganisms in raw milk have been generally killed, but some other microorganisms will be retained. Therefore, this kind of milk is required to be refrigerated at about 4 ºC in transportation, sales, storage and other links, so as to prevent the microorganisms in it from "active". Therefore, pasteurized milk is also called "refrigerated milk".

Output: 200-5000l / h

Final product packaging: plastic bags, plastic cups, plastic bottles, glass bottles, etc.

Our strengths:*It can be designed according to the special requirements of users

*Multiple products can be produced on the same production line

*It can produce high quality products and keep nutrients

*Aromatic substances can be added and mixed precisely

*Extend the shelf life of products

*Large output and small loss

*Application of high technology to save energy consumption*According to the customer's choice, we can provide a variety of milk configuration.

Milk cold storage tank, used to store fresh milk for a long time. The milk is cooled to 10 ºC as it enters the tank, and then it is cooled to 4 ºC

Milk cold storage tank, used to store fresh milk for a long time. The milk is cooled to 10 ºC as it enters the tank, and then it is cooled to 4 ºC High pressure homogenizer. The fat particles in the milk are broken and refined to make it more uniform and taste better without stratification.

High pressure homogenizer. The fat particles in the milk are broken and refined to make it more uniform and taste better without stratification.

Milk tank. It is used for pasteurization, cooling and flavoring of milk. And used for yoghurt fermentation and breaking.

Cheese making machine. Used for pasteurization, fermentation, curdling, demulsification of milk, pressing of cheese, etc.