Continual Tapioca Chips Processing Line Cassava Chip Production Line

Shandong Loyal Industrial Co., Ltd.- Certification:CE, ISO9001

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Popcorn, Chips, Biscuit, Donut

- Customized:Customized

Base Info

- Model NO.:LY65 LY70 LY75

- Equipmenew Automatic Noodles Makint Name:Continual Tapioca Chips Processing Line

- Frequency Converter:Delta Brand

- Machine Material:Stainless Steel

- Product Formula:Seller Provide Formula

- Warranty Period:12 Months

- Applicable Industry:Food Processing Machine

- After Sales Service:Seller Send Engineer for Installation and Training

- Spare Parts:Provide by Seller

- Delivery:Arrange by Seller

- Certificate:SGS,CE

- Automatic:Fully Automatic

- Key Words:Dog Food Extrusion Machine Plant

- Usage:Floating Fish Food Machine

- Voltage:Customer Settings

- Company Type:Real Factory

- Transport Package:Film&Wooden Box Packing

- Specification:2.5*1.2*1.5m

- Trademark:LOYAL

- Origin:Jinan, China

- HS Code:8438800000

- Production Capacity:5000 Sets,Year

Description

Basic Info.

Model NO. LY65 LY70 LY75 Equipmenew Automatic Noodles Makint Name Continual Tapioca Chips Processing Line Frequency Converter Delta Brand Machine Material Stainless Steel Product Formula Seller Provide Formula Warranty Period 12 Months Applicable Industry Food Processing Machine After Sales Service Seller Send Engineer for Installation and Training Spare Parts Provide by Seller Delivery Arrange by Seller Certificate SGS,CE Automatic Fully Automatic Key Words Dog Food Extrusion Machine Plant Usage Floating Fish Food Machine Voltage Customer Settings Company Type Real Factory Transport Package Film&Wooden Box Packing Specification 2.5*1.2*1.5m Trademark LOYAL Origin Jinan, China HS Code 8438800000 Production Capacity 5000 Sets/YearProduct Description

CONTINUAL TAPIOCA CHIPS PROCESSING LINE CASSAVA CHIP PRODUCTION LINE

PRODUCT DESCRIPTION

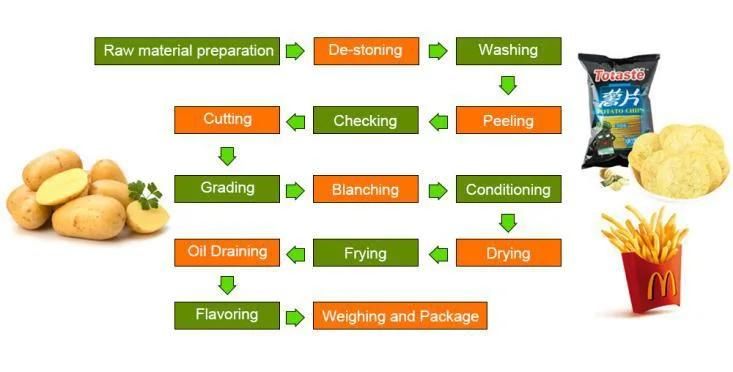

The potato chips is one kind of snack processed from fresh potato chips after washing, peeling, slicing, frying and flavoring. It remains the special the delicious flavor of roasted potato and has the characteristics of rich nutrition, delicious, convenient on the other and thus won the favor of the consumer.

HOW TO MAKE THE FRESH POTATO TO POTATO CHIPS AND FRENCH FRIES/FROZEN POTATO STICK.

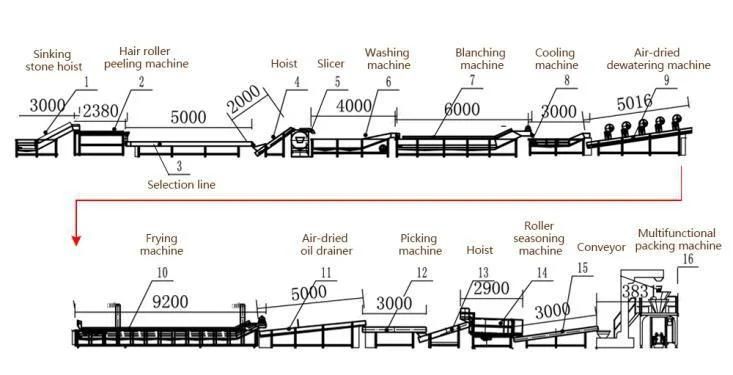

Cleaning And Peeling Potatoes - Cutting- Rinsing - Blanching - Vibration Draining - Deep Frying - Deoiling (Air Drying and Lifting) - Spices Mixing - Weighing and Packing.

FLOW CHART OF CONTINUAL TAPIOCA CHIPS PROCESSING LINE

FLOW CHART OF CONTINUAL TAPIOCA CHIPS PROCESSING LINE

1. Peeling: firstly, the potatoes shall be washed and peeled by the potato washing and peeling machine.

2. Cutting:Cutting the fresh potato into strips or chips

3.Rinsing:put the potato strips into the ozone disinfection vegetables washing machine and rinse out the mucus on the surface.

4.Blanching: after rinsing, put the potato strips into the blanching machine for inactivating the oxidase in potato strips, preventing color deterioration and accelerating dehydration

5.Vibration draining: Shifting and removing the extra water in the chips or sticks.

6.Frying: after dehydration, the potato strips will be conveyed into the frying machine for deep frying by the lifting conveyor.

7.Deoiling (air drying and lifting): after deoiling processing by the air drying and lifting machine, the fried potato strips is sent to the spices mixing machine for flavoring.

8.Spraying Flavoring :the spice mixing machine is provided with the dip type seasoning drum which can automatically control the rotate speed and capacity of materials. The machine is equipped with automatic feeding device and the feeding capacity is adjustable. It can fully mix the potato strips with the spices.

9.Packing :after seasoning, the potato stripes are conveyed by lifting conveyor to the packing machine for vacuum packing or normal packing. The weighing device may be provided if it is necessary.