Stainless Steel Jacket Insulation Mixing Tank for Cosmetic, Food and Pharmaceutical ...

Shanghai Kaiquan Machine Valve Co., Ltd.- After-sales Service:Online Service

- Warranty:One Year

- Process:Mild Processing

- Power Source:Electric

- Certification:CE, ISO9001

- Automatic Grade:Automatic

Base Info

- Model NO.:KQ Series

- Application:Milk, Yogurt, Milk Powder

- Customized:Customized

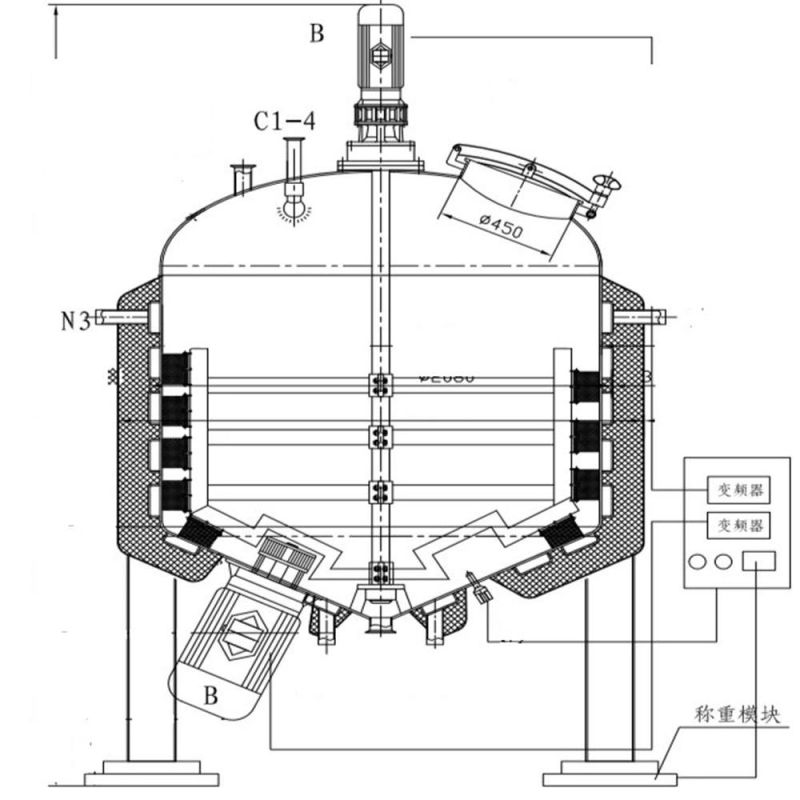

- Name and Description:Stainless Steel Jacket Insulation Mixing Tank for

- Material:Food Grade Stainless Steel 304,316

- Stainless Steel Tank:Mixing, Heating, Cooling, Storage Liquid

- Type:Double Wall ,Jacket Wall

- Capacity:100L~10000L

- Usage:Milk, Yogurt, Juice etc .

- Condition:New

- Place of Origin:Shanghai China

- Voltage:Follow Your Request

- Heating:Electric ,Steam ,Gas

- Tank:Inside Wall, Jacket Wall, Outside Wall

- Surface Treatment:Inside Mirror and Outside Polished

- MOQ:1st

- Packing:Wooden Box .

- Motor:Siemens ,ABB,China Brand

- Transport Package:Standard

- Specification:ISO

- Trademark:KQ

- Origin:China

- HS Code:8479820090

- Production Capacity:1000

Description

Rotating 20, 35, 50,

100, 500

Stepless speed reducer or inverter reducer available

Feature:

1: Blending system adopts single-direction or double-direction wall scraping blending to satisfy different technological requirement

2: Frequency conversion speed adjustment.

3: Material can be heated or cooled according to tech stand mixer nological requirements

4: Electric heating or steam heating

5: Various forms of blending vanes are suitable for production of different types of products.

6: Made of imported SUS304 or SUS316L stainless steel. The tank body and pipe are subjected to mirror polishing

7: Bottom installation type dispersing head and FLUKO pipeline type emulsifying head are optional to speed up dissolution and emulsification of materials.

8: The stainless steel electric control cabinet can completely supervise the operation of equipment, and display such data as temperature and blending rotation speed, etc

9: High-speed disperse (homogenizer) strongly mixed decentralized thick, solid, liquid.

Cosmetic producing machine; Cosmetic producing machine; Cosmetic producing tank; Daily chemical stirring vessel; Detergent agitator boiler; Detergent agitator pot; Stainless steel blending pot; Stainless steel blending machine; Stainless steel blending tank; Stand mixer; Static mixer

Sanitary stainless steel Heating and Cooling Tank

Rotating 20, 35, 50,

100, 500

Stepless speed reducer or inverter reducer available

Sanitary Stainless Steel Cooling Mixing Heating Fermentation Tank

Sanitary Stainless Steel Cooling Mixing Heating Fermentation Tank

Stainless Steel Jacket Insulation Mixing Tank for Cosmetic, Food and Pharmaceutical Industry

Stainless Steel Jacket Insulation Mixing Tank for Cosmetic, Food and Pharmaceutical Industry