200kg/h Cassava starch processing machine line

Henan VIC Machinery Co., Ltd.- After-sales Service:online

- Warranty:1 year

- Type:processing line

- Voltage:380V

- Power:55.8kw

- Customized:Customized

Base Info

- Model NO.:MSX-200

- Capacity:200KG,H cassava powder

- Transport Package:Wooden Box

- Specification:20X10X8M

- Trademark:VIC

- Origin:Chian

- Production Capacity:500set,Year

Description

Basic Info.

Model NO. MSX-200 Capacity 200KG/H cassava powder Transport Package Wooden Box Specification 20X10X8M Trademark VIC Origin Chian Production Capacity 500set/YearProduct Description

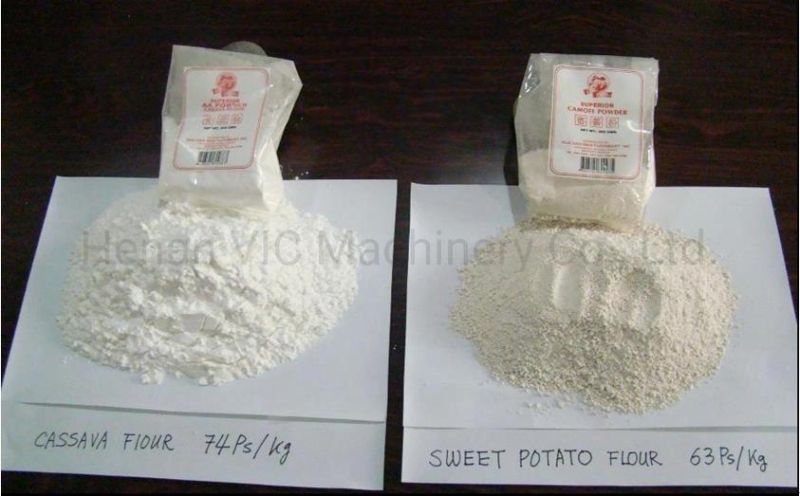

200kg/h Cassava starch production lineIntroduction:Cassava powder, it is in powder shape, it's the processing product of cassava root, and kept the nutrition of cassava, and it's the main food of Africans, cassava powder/flour can be eat directly or as food raw materials.

Cassava powder processing and cassava starch difference:

- Cassava powder cleaning is the main part of cassava powder processing because cassava powder have no water cleaning filtering process. And cassava has roller type peeling cleaner, mainly used to remove the silt of the cassava and cassava skin.

- Cassava crushing is different as simple crushing of cassava starch processing, when crushing its better to add less water or no more water, and fineness have higher requirement, after crushing the cassava the materials usually no need filter to avoid loss of nutrition.

Cassava powder processing: cleaning-crushing-dehydration-dry-pack, all the process connected and can be full auto process.

Fresh cassava after cleaning and removing impurity---transfer to crusher---after crushing the slurry go to dehydration---transfer to drying equipment--- dried material go through selecting---final product package.

Technological process:

Washing machine--crusher--dehydrate machine-- feeding machine-- dryer-- vibrating screen

Raw materials requirement:

Fresh cassava, in 24 hours, fresh cassava moisture content around 60%, starch content 25-30%, fibre and other tiny materials 1-5%, protein content 1-5%. Final product of cassava flour mesh around 80-100m, and moisture less than 14%

Main equipment :

| Model | Name | Qu'ty (set) | Power (kw) | Capacity (kg/h) | Steel |

| QX-100 | Washing machine | 1 | 4 | 1000kg/h | Contact materials ss |

| RP-60 | Cassava crusher | 1 | 15kw | 1000kg/h | Plain carbon |

| MT-500 | Dehydrate machine | 1 | 4 | 200kg/h | Contact materials polypropylene |

| HWL-2 | Feeding machine | 1 | 3kw | 200kg/h | Contact materials ss |

| FG-0 | Dryer | 1 | 18.5 | 200kg/h | Contact material ss |

| FM-330 | screen | 1 | 11kw | 400kg/h | Plain carbon steel |

Every ton powder need consumpt around 35-50 kw, oil need around 45-55Liter, water around 3 m3.

More picture :

Washing machine

Crusher

Dehydrate machine

Feeding machine

Dryer

Screen

Cassava after washing

Cassava powder

Customer site

Our factory