30 Ton Per Day Maize Flour Mill Machine

Shijiazhuang Hongdefa Machinery Co., Ltd.- Type:Flour Mill

- Application:30t Maize Mill Equipment

- Voltage:380V

- Appearance:Vertical

- Press Materials:Corn

- Press Series:Fourth

Base Info

- Model NO.:30 ton per day

- Condition:New

- Customized:Customized

- After-Sales Service:Engineer Available to Service Machinery Overseas

- Brand Name:Hongdefa

- Processing Type:30 Ton Per Day Corn Grits Maize Flour Mill Equipme

- Final Production:Super Fine Maize Flour

- Material:Steel

- Branch Office:Zambia Uganda Ethiopia

- Certification:Ce Bc SGS ISO9001

- Market:Africa

- Transport Package:Standard Export Packing

- Trademark:Hongdefa

- Origin:China

- Production Capacity:5t 10t 20t 30t 50t 100t 150t 200t

Description

Basic Info.

Model NO. 30 ton per day Condition New Customized Customized After-Sales Service Engineer Available to Service Machinery Overseas Brand Name Hongdefa Processing Type 30 Ton Per Day Corn Grits Maize Flour Mill Equipme Final Production Super Fine Maize Flour Material Steel Branch Office Zambia Uganda Ethiopia Certification Ce Bc SGS ISO9001 Market Africa Transport Package Standard Export Packing Trademark Hongdefa Origin China Production Capacity 5t 10t 20t 30t 50t 100t 150t 200tProduct Description

30 ton per day maize flour mill machine

maize flour mill machine of 10t 20t 30t 50t 100t

100T 200T 300T maize flour mill machine

high standard maize flour mill machine factory

For our maize flour mill machine, we have different capacity, from 5T/24H to 2000T/24H for your choice. If you are the starter, we suggest you the small capacity like 20T 30T maize mill50T 100T maize mill, if you need big capacity, you can choose the 200t 300t maize flour mill equipment 500t or 1000t kinds.

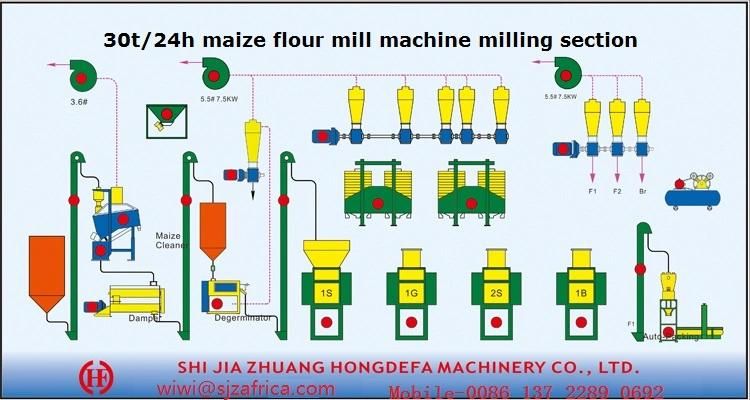

Here we mainly introduce the 30T/24H maize mill machine for your reference:

The 30T maize flour mill machine, we use the European standard design with Automatic control system, including precleaning cleaning milling and auto-packing system.

They are the two lines of 30t maize flour mill equipment which we installed in our China factory and installed in South Africa. Welcome to visit the running line in China.

1) cleaning section technique flow for maize flour mill equipment:

Bucket elevator -- Maize cleaner -- Moisture damper (stainless steel)-- damper bin -- Screw conveyor --Magnetic separator-- Degerminator -- Gravity grade sifter -- blower -- Impulse dust filter

2) milling section technique flow for maize flour mill machine:

Pneumatic roller mill -- Square plansifter -- Aspirator -- blower -- Flour screw conveyor -- Air seal -- Impulse dust filter -- Auto-weighting& packing scale -- Belt Screw Compressor system

Final maize products from the maize flour mill machine line:

Maize big grits, maize small grits, maize rice, maize samp, maize meal, maize flour and maize bran.

Maize grits can be the material for beer, small grits can be the materia for snack food, maize flour for human consumption and maize bran for animal feed.

If you want to get the exactly detail list about this 30t maize mill equipment, please send me inquiry or talk with me by the online chatting tools, I will send you all the detail list with drawing and best price at the first time.

Here are some photos and introduction for the main machines of the maize flour mill equipment:

1, Roller mill in maize mill machine

The mill is the most important one machine of whole processing line, is mainly for grinding. To break maize and bran's structure, and spearate the maize bran and the embryo from endosperm by grinding.

1)The partitioned paneling and swing-out feed module guarantee ideal access to the feeding and grinding rolls. This makes residue-free cleaning possible.

2) a pulse generator automatically adjust the feed material at the entrance door

3) bearing SKF

4) temperature monitor (option)

2, Plansifter in maize flour mill line:

Plansifter can classify the material that from break, reduction and scratch systems and sifting the flour to make sure can get the super white maize mes aal maize gritnd maize flour.

1) Material: High-strength alloy steel

2)up and down sifter circles with steel plate overall by bending

3)Transmission system using spring force component institutions

4)Sieve frames of wood coated with synthetic resin,without backwire

5)All the inside walls as well as the doors are provided with high-grade insulation

6)Vertical and horizontal clamping system

3, Automatic packing system in maize flour mill equipment:

E-measurement technology, realized automatically fill; automatic detect weight;automatic measure the number of the bags.

It has different packing weight: 10kg 12.5kg 20kg 25kg and 50kg

Air source: Air pressure P≥0.6Mpa

Air supply rate Q≥1.2m3/min

packing accuracy :FS±2‰

1) Online auto cumulative weight

2)High-precision on-line flow control;

3)Frequency (batch) weight control;

4)With MODBUS communication interface with computer networking, computer centralized management control;

5) According to customer needs, can have the print function.

6)Feeding and support is stainless steel

4. Pipes in the maize mill system:

Stainless steel pipes in milling section where contact with material.

Stainless steel pipes is high quality and anty-rusty, the whole line looks beautiful, shinning and cleaning.

Our maize flour mill equipment factory introduction:

We are a professional manufacturer for maize mill machine in China.

With European technology, South Africa maize process, China wheat process, we roll out unique and innovative wheat flour mill and maize/corn mill plants.

Every year there will be many clients from different countries (such as Zambia Kenya Uganda South Africa Tanzania Benin Ghana Nigeria and so on ) come to our factory in China to check the real maize flour mill equipment, the running lines which can produce the maize flour when they come then make the final order.

Contact informaiton:

Now send your inquiry to me or talk with me online to ask more for the maize flour mill equipment. You also can find me through the below way:

Send your message to this supplier