Tray Type Rotary Maker Soft Biscuit Moulding Printing Machine Sky400/600

Foshan Shunde Skywin Foodstuff Machinery Co., Ltd.- Usage:Biscuit, Cookie

- Power Source:Electric

- Timing Device:With Timing Device

- Type:Moulder

- Voltage:220V

- Customized:Customized

Base Info

- Model NO.:SKY400,600

- Biscuit Equipment:Biscuit Maker

- CE:Food Processor

- Automatic:Biscuit Making

- Bakery Machine:Cookie Making

- Vertified:ISO9001 CE SGS

- Transport Package:Wooden Case Delivery

- Trademark:Skywinbake

- Origin:Guangdong, China

- Production Capacity:50kgs,Hour~180kgs,Hour

Description

Basic Info.

Model NO. SKY400/600 Biscuit Equipment Biscuit Maker CE Food Processor Automatic Biscuit Making Bakery Machine Cookie Making Vertified ISO9001 CE SGS Transport Package Wooden Case Delivery Trademark Skywinbake Origin Guangdong, China Production Capacity 50kgs/Hour~180kgs/HourProduct Description

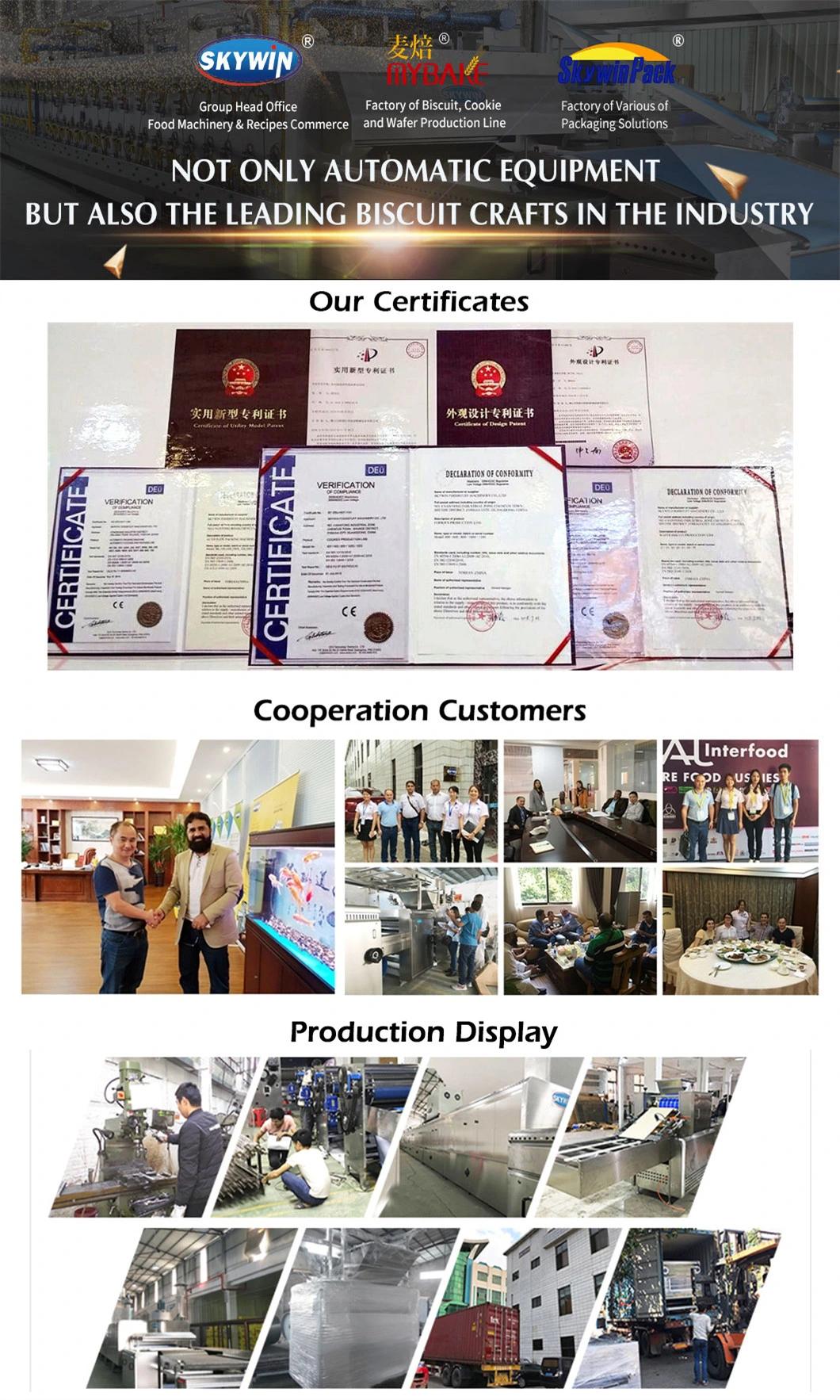

Skywin is a professional manufacturer and exporter that is concerned with the design, development and production of Biscuit Production Lines and Cookie Production Lines in China for 30 years working experience. ·Skywin Model 400/600/800/1000/1200/1500 mm, capacity from 100-1800 kg/hr.

·Skywin Model 400/600/800/1000/1200/1500 mm, capacity from 100-1800 kg/hr.·It is widely available for making all kinds of biscuits( Hard and Soft biscuit, Soda Cracker, Cookies, also Stick biscuit, Potato chips, hello panda biscuit, Print biscuit and Chocolate filling biscuit)

·Different shape biscuit just need to change the mold, we also can design mold for you according to your requirement.We have a unique development of rapid disassembly device can allow you to change the mold in a very short time to reduce the waste of labor and time.

Rotary Moulder

Rotary Moulder

| Brand | Skywin | Article | SKY-400/600 |

| Warranty | 1 Year | Certification | ISO9001/CE |

| Cylinder | Air TAC | Material | Full #304 stainless steel |

| Moulding Speed | 16m/min | Motor/Gearbox | SEW Motor/Chinese famous Brand Motor for option |

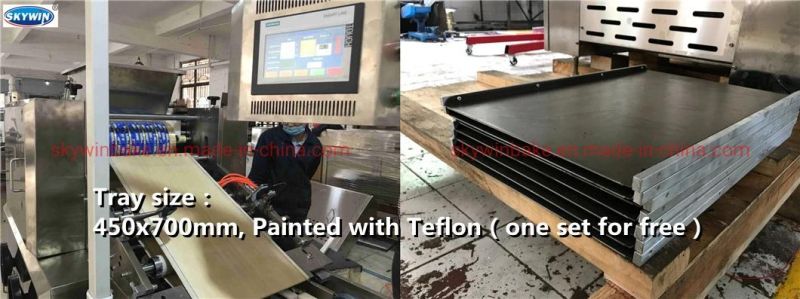

| PU Belt width | 400mm-600mm | Control | PLC Touch Screen Control |

| Bearing | NSK | Transducer | SIEMENS |

Rotary moulder is used in making Soft biscuit. After dough crushed by roller then go through moulder to forming.Single operation system, it is also can be controlled by combine with whole line.

Feeding roller and crosswise milling has groove, enable the feeding sufficiently

The distance between feeding roller and biscuit moulds is adjustable.

Rubber roller can be adjusted on either side or both sides to reduce the deviation of biscuit weight among lines.

The linear speed of the conveyor of biscuit mould is identical with the de-mould roller, therefore reducing biscuit deformation

All of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

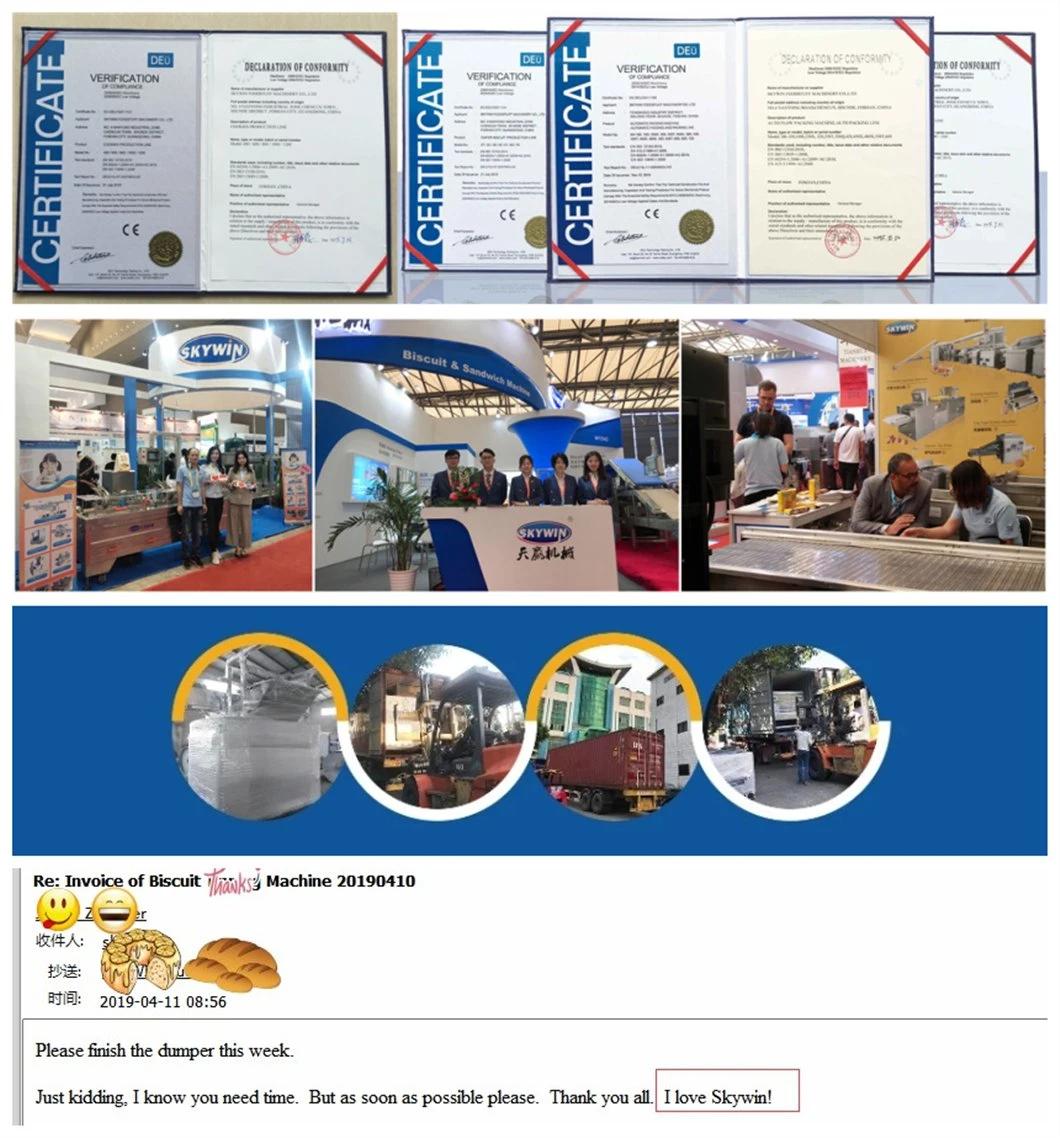

Packing&Delivery:

Packing&Delivery:Our regular packaging is multilayer packing, safe transport, shipping by sea:

Step 1: Mechanical surface coated with preservative solution (to protect stainless steel).

Step 2: The plastic cushion packing machine (prevent bump).

Step 3: Plastic film packaging (to prevent ventilation).

Step 4: Wooden case / frame packaging (easy to transport).

Step 5: Tie the bandage outside of the wooden case (reinforcement overall).

FAQ

Q1: Which kind of biscuit you can produce for your biscuit line?

A. Hard and Soft biscuit, Soda Cracker, Cookies, also Stick biscuit, Print biscuit and Chocolate filling biscuit, different shape biscuit just need to change the mould, we also can design mould for you as per your details.

Q2. What kind of oven you supply?

A. We can supply gas oven or electrical oven according to your requirement.

Q3. How long is your biscuit line?

A. we can design the biscuit line according to the layout of your workshop.

Q4. Which brand of motor you use for the line?

A. we can supply European motor reducer(SEW) or Chinese famous motor for your options.

Q5. Are you manufacturer?

A. Yes, we are a biscuit machine manufacturer in China.

Q6. How is the payment?

A. We accept 40% T/T deposit before production and 60% T/T balance before shipment,and Western Union or L/C.