How to Remove Hulls From Sunflower Seeds by Machine

YANGZHOU COYOTECH MACHINERY CO., LTD.- Type:Grain Coarse Cereals Processing Equipment

- Application:All, Beans, Sunflower

- Voltage:Customized

- Condition:New

- Customized:Customized

- Trademark:COYO

Base Info

- Production Capacity:50000PCS,Year

- Origin:China

Description

Basic Info.

Origin China Production Capacity 50000PCS/YearProduct Description

How To Remove Hulls From Sunflower Seeds By Machine?

By Hand? Then You Can Turn Off This Page!

Of Course, Machines Can Be Used. SO What Kind Of Machines Can Be Used?

LOOK AT THIS!

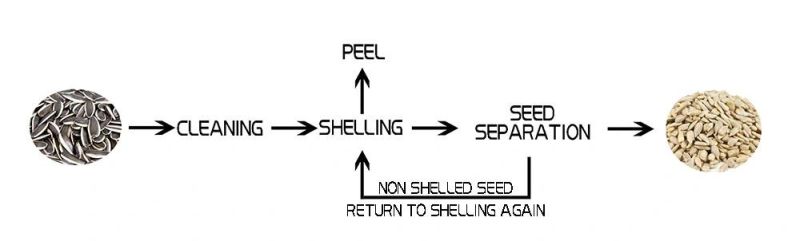

The Overall Processing Flow Chart

1,Feeding hopper,

2,raw material elevator,

3,multi-function impurity remover (cleaner),

4,bucket elevator,

5,double sheller,

6,Classifier (3 sets),

7,receiving hopper,

8,wind return system,

9,control cabinet

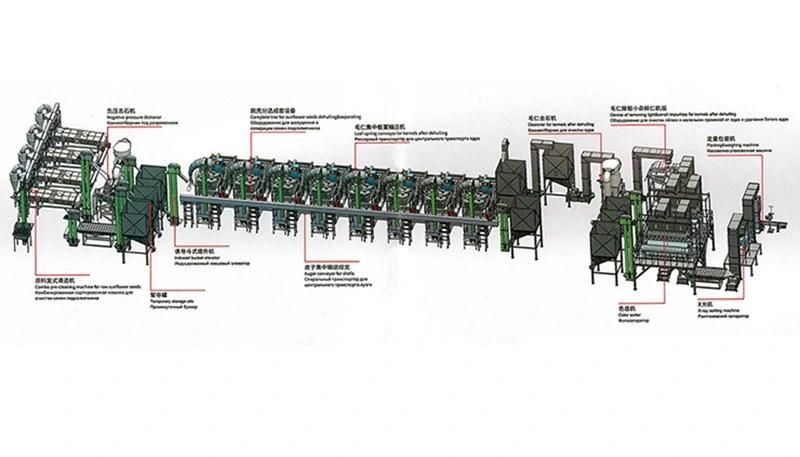

Usually In A Large Sunflower Seed Processing Plant, It Needs These Equipment To Complete The Conversion From Raw Sunflower Seed To Sunflower Seed Commodity

But Sunflower Seed Shelling Equipment Is A Very Key Core Technology

This Is Sunflower Seed Shelling Equipment Produced By Our Company

1,Feeding hopper,

2,raw material elevator,

3,multi-function impurity remover (cleaner),

4,bucket elevator,

5,main part of the equipment(dehullers,air separator and seed-kernel separator),

6,pneumatic system of back-flowing materials,

7,seed-kernel reseparator1,

8,seed-kernel reseparator2,

9,kernels bin,

10,control cabinet

It Relevant Technical Parameters

Power: 20.24 kW (380 V)

Raw material handling capacity: 0.8-1.25 T / h (3.2 mm. Sieve)

Whole kernel rate: ≥ 90% (1 / 2 and more than 1 / 2 are whole kernels)

Seed content in kernel: 2-5%

Kernel content in skin: ≤ 0.5%

Floor area: 13.1m × 2.92M

Installation height: 5.4m

Equipment weight: 6 tons

If you have any need, please feel free to contact me at anytime!