Flour Milling Processing Equipment Water Cleaning Machine Wheat Washing Machine

YANGZHOU COYOTECH MACHINERY CO., LTD.- Type:Flour Mill

- Application:Flour, All, Wheat, Rice flour

- Voltage:Customized

- Appearance:Vertical

- Condition:New

- Customized:Customized

Base Info

- Model NO.:Wheat Washing Machine

- Color:blue and White

- Transport Package:Wooden Box

- Trademark:COYO

- Origin:China

- Production Capacity:50000PCS,Year

Description

(L×W×H)mm

This Machine Can Achieve The Following Performance Indicators:

The sand content of raw grain should be no more than 0.3%,

When the moisture content is not more than 12%,

The sand content of raw grain should be no more than 0.3%,

When the moisture content is not more than 12%,

The machine can achieve grain growth rate of 0.8-3%;

The ash content decreased by 0.02-0.04%;

The crushing rate is not more than 0.5%;

The sand content of the sand machine is less than 0.03%;

The water consumption is 200-400 kg / T.

Working Principle

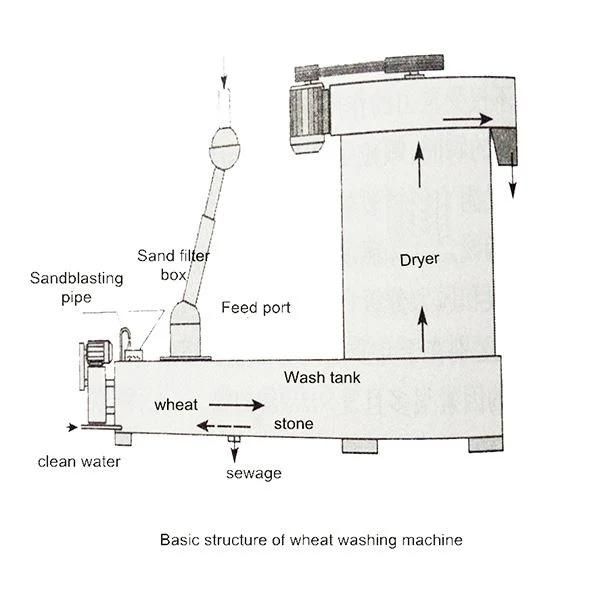

This machine is mainly composed of wheat washing water tank and dryer. With feeding, transmission, drainage, sand discharge, ventilation and other auxiliary devices.

The water tank part of wheat washing machine: it is welded by steel plate. The upper part of the inner side of the water tank is equipped with a wheat washing auger, the lower part is equipped with a stone removing auger, and the other side is equipped with a sewage discharge device.

The direction of conveying is opposite to that of washing machine. When wheat falls into the excited water flow, the water in the water tank agitates. When the wheat falls into the excited water flow, the wheat is suspended because of its small specific gravity and can't sink immediately, so it is gradually pushed to dryness by the leaves of the wheat galloping dragon The sand and gravel contained in the wheat and the heavy sediment washed down rapidly sink in the water due to the large specific gravity, and are gradually sent out by the stone removing dragon in the opposite direction to the flow of wheat, so that the wheat and the mixed sand and gravel can be separated.

Lifting and drying: after washing in the water tank, the wheat is transported to the dryer by the wheat washing auger and lifted by the spiral swinging plate. At the same time, due to the centrifugal force generated by the high-speed rotation of the dryer, the washed wheat is dried (meeting the process requirements in flour milling), and then discharged from the wheat outlet to enter the next process. When the washed wet wheat enters into the high-speed rotating throwing board through the bottom of the dryer, the swinging board throws the wheat with moisture to the screen on one side, and transports the wheat upward on the other side. Under the action of centrifugal force generated by high-speed rotation, the surface moisture of wheat is thrown away, and the water flows out of the screen hole; The accelerated ventilation air flow caused by the rotation of the swinging plate makes the surface of the wheat grain dehydrated and dried, and the dried wheat is discharged from the outlet of the top cover.

About us