Meat in Glass Jar Sterilizer and Tin Can Retort Autoclave

Qingdao Evertech Industry Co., Ltd.- Customized:Customized

- Certification:CE, FDA, EEC, ISO13485, Ce

- Scale:Medium

- Automation:Automatic

- Principle:Sterilizer

- Structure:Tunnel

Base Info

- Model NO.:DN800*1000 sterilization

- Operation:Continuous

- Energy:Heat Sterilization

- Property:Physical Sterilization

- Type:Autoclave

- Power(Kw):2kw

- Weight:650kg

- Dimension(L*W*H):1100*1300*1500

- Warranty:12 Months

- After-Sales Service Provided:Engineers Available to Service

- Transport Package:Wooden Case

- Specification:220V 260V 380V 450V

- Trademark:Evertech

- Origin:Shandong, China (Mainland)

- HS Code:8419899090

- Production Capacity:5 Set,Sets Per Month

Description

Item

Sumpot

Other brands

Door flange

The 2 stages loose door with national patent , the door open process is divided into two stages.

Ordinary open door

Pressure detection of door sealing

The sterilization retort has the pressure monitoring system of the sealing ring. If it is not inflated or the inflating pressure is insufficient, the retort will not run and give alarm signals .

none

Thermal insulation layer

Thickness 50mm

Thickness 30mm

Water level indicator

Magnetic floating level gauge

Glass tube level gauge

Pure manual control

When an abnormal system is unable to operate automatically, the operator can perform pure manual operation.

none

Barrel liners

Wire drawing process

sand-blasting process

Trolley stabilizer

When load the basket,helping the trolley safety connect to the retort

none

Door open mood

The cylinder automatically turns the door open

manual

non-volatile memory

The system can remember the process, continue to work follow the procedure after a short outage

none

Bead passivation

All welding parts are treated with passivation

none

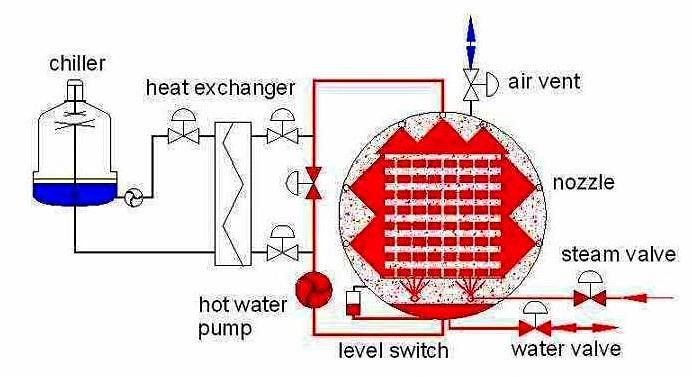

WATER SPRAY sterilizer autoclave WORKING PRINCIPLE

FEATURES

• sterilizer retort Excellent temperature distribution

• sterilizer retort Continuous process water

recirculation

• autoclave sterilizer retort Powerful steam and waterspray

heating

• sterilizer retort Efficient cooling

• sterilizer retort Top spray for cans or glass jars

• Side spray for trays or pouches

• sterilizer retort Continuous water level control and flow monitoring

• Programmable air-overpressure control

• Steam and water consumption minimal

how does the sterilizer retort autoclave work?

1. WATER FILLING sterilizer retortautoclave

Prior to the start of the process, the retort is filled with a small volume of

process water (approx. 27 gallons/basket) such that the water level is below

the bottom of the baskets. This water can be used for successive cycles if

desired, as it is sterilized with each cycle.

2. HEATING sterilizer retortautoclave

Once the cycle is begins, the steam valve opens and the circulation pump is

switched on. The mixture of steam and water spraying from the top and the

sides of the retort vessel creates highly turbulent convection currents that

rapidly homogenizes the temperature at every point in the retort and

between the containers.

3. STERILIZATION sterilizer retortautoclave

Once the programmed sterilization temperature has been reached, it is held

for the programmed time within +/- 1º F. Similarly, the pressure is kept

within +/- 1 psi by adding and venting compressed air as needed.

4. COOLING sterilizer retortautoclave

At the end of the sterilization step, the retort switches into cooling mode. As

the process water continues to be circulated through the system, a portion of

it is diverted through one side of a plate heat exchanger. At the same time,

cold water passes through the other side of the plate heat exchanger. This

results in the process water inside the retort chamber being cooled in a

controlled fashion.

5. END OF CYCLE sterilizer retortautoclave

Once the retort is cooled to the programmed temperature setpoint, the cold

water inlet valve on the heat exchanger closes and the pressure inside the

retort is automatically relieved. The water level is lowered from the

maximum down to the medium level. The door is equipped with a safety

locking device which prevents the opening of the door in the case of residual

pressure or high water level.

PLC control type automatic sterilizer retort autoclave

with CE certificate

buy best price sterilizer retor from manufacture in China

best price sterilizer sterilization equipment on sell manufacture of sterilizer

sterilizer retort autoclave manufacture