Low-Cost Vacuum Fruits Fryer/Energy-Saving Vacuum Frying Machinery for Sale with Ce

Shandong Loyal Industrial Co., Ltd.- After-sales Service:Provide

- Warranty:12 Month

- Certification:CE, ISO9001

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

Base Info

- Application:Popcorn, Chips

- Customized:Customized

- Equipment Name:Industrial Vacuum Frying Line

- Frequency Converter:Delta Brand

- Machine Material:Stainless Steel

- Product Formula:Seller Provide Formula

- Warranty Period:12 Months

- Applicable Industry:Food Processing Machine

- After Sales Service:Seller Send Engineer for Installation and Training

- Spare Parts:Provide by Seller

- Delivery:Arrange by Seller

- Certificate:SGS,Ce

- Automatic:Fully Automatic

- Key Words:Industrial Vacuum Frying Line

- Place of Origin:Jinan,China

- Voltage:Customer Settings

- Company Type:Real Factory

- Transport Package:Film&Wooden Box Packing

- Specification:2.5*1.2*1.5m

- Trademark:Loyal

- Origin:Jinan, China

- HS Code:8438800000

- Production Capacity:5000 Sets,Year

Description

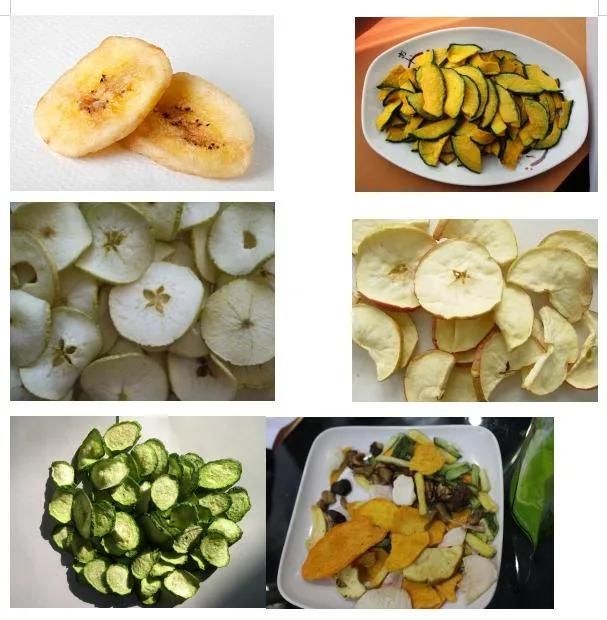

II.Usage&Sample:

1 fruit: apple, kiwi, wood grapes, persimmons, strawberries, grapes, peaches, pears, etc.;

2 vegetables: tomatoes, sweet potatoes, potatoes, green beans, mushrooms, mushrooms, garlic, carrots, green peppers, Pumpkin, onion, etc.;

3 dried fruits: jujube (ash jujube, jujube, Hami jujube), peanuts, etc.;

4 aquatic products and livestock and poultry

Low-temperature vacuum frying can prevent the deterioration of edible oils and fats, and it is not necessary to add other antioxidants, which can improve the repeated utilization of oil and reduce costs. Generally, the oil content of fried foods is as high as 40% to 50%, while the oil content of vacuum fried foods is 10% to 20%, and the fuel economy is 30% to 40%, and the fuel saving effect is remarkable. The food is crispy but not greasy and has good stability.

Under vacuum, the water in the cell gap of fruit and vegetable is rapidly vaporized and expanded, the gap is enlarged, the puffing effect is good, the product is crisp and delicious, and has good rehydration performance.

III.Vacuum frying process:

Raw materials → Screening → Cleaning → Slicing (cutting) → Killing (protection) → Draining → Freezing → Thawing → Dipping (vacuum dipping) → Cleaning → Draining → Vacuum frying → Vacuum deoiling → Seasoning → Product packaging → Storage.

IV,Paramater of the Frying Machine

| ModelParameter LD-600 /LD700/LD1000/lD1200 Processing capacity (raw material Kg / time) 600 Production (Kg/time)) 200-400 Processing time (min/time) 25-60 Ultimate vacuum (MPa) - 0.092~-0.096 Oil temperature (°C) 80~100 2, Heating source Steam consumption (Kg/h) 250 Steam pressure (MPa) 0.4~0.8 Main heating method coil heating Compressed air pressure (MPa) 0.5~0.8 Deoiling number n/min 100~750 Cooling water volume (T/h) 40 Power supply 380V/220V |

RELATED EQUIPMENT:

OUR Company

Shandong Loyal Industrial Co,Ltd.

- We are real facotry located at jinan- can provide you best cost price.

2.More than 15 years experience at the food machinery field.

4. 22 engineers with more than 8 years of work experience are available 24 hours service One day.

- We pay more attention on each detials of the equipment

- We are a important leading enterprise in Shandong, providing employment opportunities for local residents, helping the poor and helping farmers, and participating in charitable activities