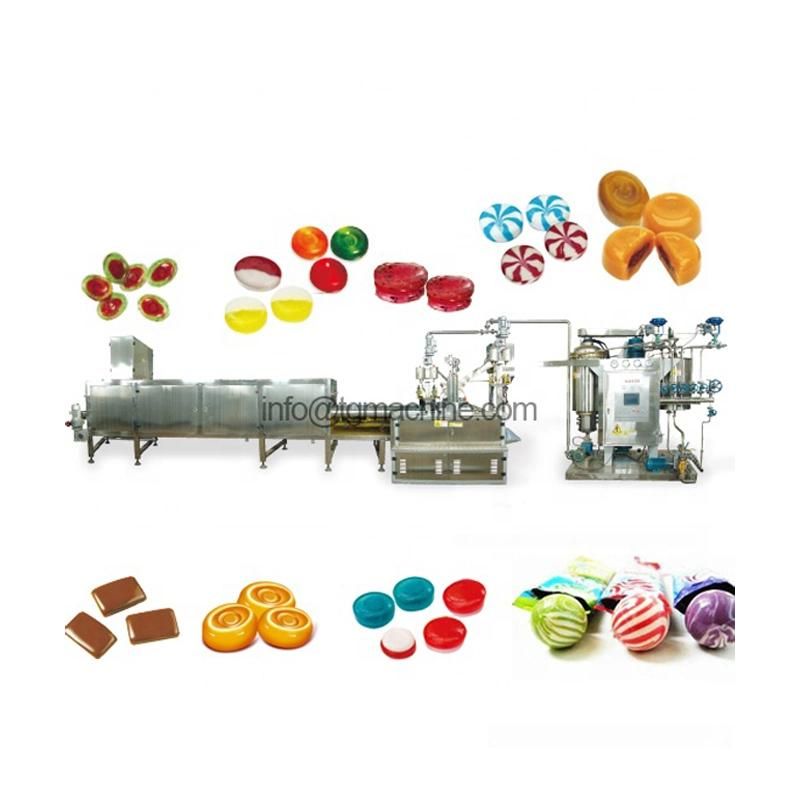

Continuous Cooking Machine for Soft-Milk Candy with Ce Certification

Shanghai Target Industry Co., Ltd.- Certification:CE, ISO9001

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Candy

- Customized:Customized

Base Info

- Model NO.:SC300

- Capacity:300kg,H

- Total Power:5.5kw

- Weight of Each Batch:160kg

- Voltage:380V,220V

- Transport Package:Wooden Packaging

- Specification:CE, ISO9001: 2000

- Trademark:tgmachine

- Origin:Shanghai

Description

Basic Info.

Model NO. SC300 Capacity 300kg/H Total Power 5.5kw Weight of Each Batch 160kg Voltage 380V/220V Transport Package Wooden Packaging Specification CE, ISO9001: 2000 Trademark tgmachine Origin ShanghaiProduct Description

Features:

1.The cooker is specially designed for producing the high-quality toffee candies.It uses the steam jacket cooking style.

2.It equipped with the rotating speed-adjusted scrapers to avoid the burning during the cooking.It also can produce a special caramel flavor.

3.The syrup is pumped from the storage tank to the toffee cooker.Then it is heated,and stirred by the rotating scrapes.The syrup is well stirred during the cooking to guarantee the high quality of the toffee syrup.

4.When it is heated to a rated temperature,open the vacuum pump to addition ally help to evaporate the more water.

5.After this vacuum,the finished syrup is out through offloading valve.The whole cooking time is about 35 minutes(160 liter syrup)

6.The machine is well reasonable designed,beauty appreance and easy for operation.It can be made of stainless steel,with PLC function and touch screen according to customer's different requirement.

Technical Parameters:

| Capacity: | 300kg/h |

| Total power: | 5.5KW |

| Weight of each batch: | 160kg |

| Cooking time: | 35min |

| Steam requirement: | 300kg/h;0.7MPa |

| Dimension: | 1800×1450×2350mm (Length ×Width ×Height) |

| Total weight: | 1500kg |

Wooden packing

1.Product production is completed, by the quality inspection department to check

2.After inspection qualified, clean for whole machine

3.Packing: a. Inside the machine put desiccant b. Add 6 cm thick foam plate around the machine, Then, winding stretch film for reinforcement, and combined with bubble wrap c. On wood packaging on the outside of the machine, then use metal reinforcement with steel

4.Container:according to different products for reinforcement