Automatic Maize Grinding Machine Flour Mill Plant Flour Mill Machinery

Hebei Africa Machinery Co., Ltd.- Type:Flour Mill

- Application:Flour

- Voltage:380V

- Appearance:Horizontal

- Press Materials:Wheat, Maize, Rice

- Press Series:European Standard

Base Info

- Model NO.:40T,24H-2400T,24H

- Condition:New

- Customized:Customized

- Capacity:40t-2400t

- Qualtiy:Grade 1

- Processing:Milling

- Processing Type:Wheat, Corn, Rice

- Flour Extraction:Standard Flour 72%-78%

- Transport Package:Suitable for Shipping

- Specification:SGS CE

- Trademark:HBA

- Origin:Hebei, China

- HS Code:84378000

- Production Capacity:40-2400t,D

Description

Basic Info.

Model NO. 40T/24H-2400T/24H Condition New Customized Customized Capacity 40t-2400t Qualtiy Grade 1 Processing Milling Processing Type Wheat, Corn, Rice Flour Extraction Standard Flour 72%-78% Transport Package Suitable for Shipping Specification SGS CE Trademark HBA Origin Hebei, China HS Code 84378000 Production Capacity 40-2400t/DProduct Description

Flour mill milling machineWheat Corn/maize flour mill machine supply 40-2400t/24hour milling machine complete processing line

Single machine

1. Advance technology

2. Quality: No. 1

3. PLC controlling system

4. Steadily running, low noise. Long using life

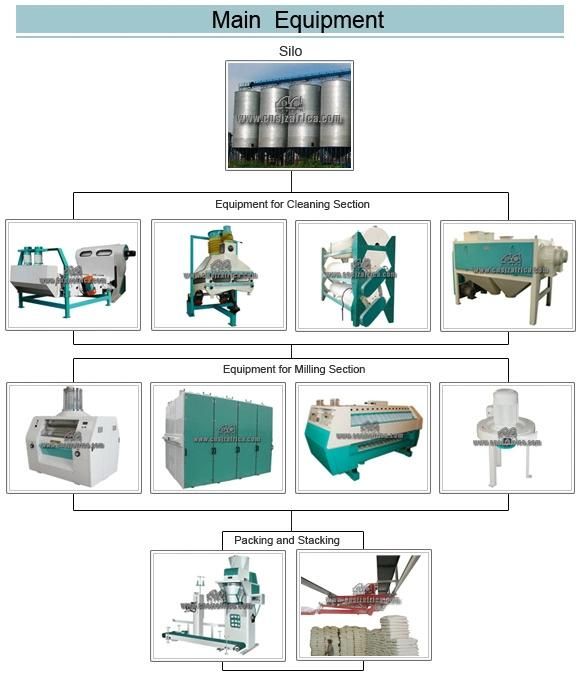

We can offer a turn key project 40T-2400T/24h complete set flour machinery. The process of wheat flour milling machinery can be divided into four parts: Cleanning part, milling part, packing part and controlling part.

1. Cleaning part

To clean out the middle and small impurity from wheat. E. G., dust, stone, magnetic material, wheat was bitten by insect and so on. Includes beating, screening, destoner, magnetic separator and dampening. This section is make the wheat to prepare for millling part and to protect the machinery as well.

2. Milling part

Include different number of mill and sifter to mill the wheat and separate the flour and bran

(1) Mill: Mill the wheat to break the integrity by the roller moving

(2) Sifter: To separate the flour and bran, also separate large size and small size to enssure flour quality.

3. Packing part.

The packing part can be manual one also can be auto one, this can be designed according to requirement and machine capacity.

4. PLC controlling system

To controlling the whole set of machinery to work well and showing the process of working