Core Filling Snack Food Production Line /Processing Line/Making Machine

Jinan Datong Machinery Co., Ltd.- Certification:CE, ISO9001

- Power Source:Electric

- Process:Mild Processing

- Automatic Grade:Automatic

- Application:Candy, Chips

- Customized:Customized

Base Info

- Model NO.:SLG65-III

- Material:Stainless Steel

- Motro Brand:Siemens Motor

- Inverter:Delta Brand

- Size:15.0*5.0.*5.0

- Snacks Raw Material:Corn Wheat Flour, Rice Flour......

- Stainless Steel Material:304

- Warranty:1 Year

- Raw Material:Corn Rice

- Electric Parts:LG, FUJI, Omron etc

- Name:Puff Snack Food Making Extrusion Machinery

- Transport Package:Woodcase

- Trademark:Jinan Datong Machinery Company

- Origin:Jinan

- HS Code:84361000

- Production Capacity:200-500kg,H

Description

Basic Info.

Model NO. SLG65-III Material Stainless Steel Motro Brand Siemens Motor Inverter Delta Brand Size 15.0*5.0.*5.0 Snacks Raw Material Corn Wheat Flour, Rice Flour...... Stainless Steel Material 304 Warranty 1 Year Raw Material Corn Rice Electric Parts LG, FUJI, Omron etc Name Puff Snack Food Making Extrusion Machinery Transport Package Woodcase Trademark Jinan Datong Machinery Company Origin Jinan HS Code 84361000 Production Capacity 200-500kg/HProduct Description

1. Core Filled Snack Food Processing Machine Description:

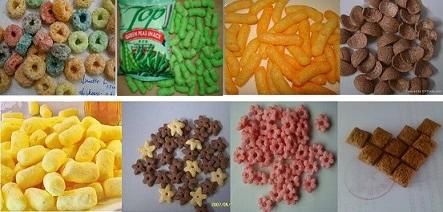

Snacks extruder adopts corn, rice, wheat, oat, barley etc as ingredients to make puffs snack. Through friction of screw and barrel, the grains are cooked in the extruder Barrel. Forming is at the die face cutter. The product shape is determined by a combination of the die aperture, including ball, tube, stick, ring, fruit loop, star, wheel and flower etc.

2. Raw materials For Snacks Food:

Adopts corn, rice, wheat, oat, barley, millet, sorghum etc as main ingredients.Other material: salt sugar powder, flavor material, cocoa powder and so on.

3. Snacks food Products shapes:

Variety shapes are available for ball, tube, stick, ring, fruit loop, star, wheel and flower and heart shape by adjusting the mould in the extruder

4. core filling snack food making machine Capacity:

100-150kg/h, 240kg/h, 500kg/h

5. core filling snack food making machine Flow chart:

Grain grinder---Mixing system---Twin screw Extrusion system----Drying system----Flavoring system--Packing system

6. China standard industrial Voltage for the machine:

Three phases: 380V/50Hz, Single phase: 220V/50Hz, We can make it according to customers' Local voltage according to different countries (400v 415v 480v....)

7. Machines Materials:

All the Snacks food machines are made by stainless steel, this whole line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function.

| Model | Installed power | Real power | Output | Dimension |

SLG65-III | 70kw | 40kw | 100 -150kg /h | 20000x1200x 2200mm |

SLG70 | 100kw | 70kw | 200 -240kg /h | 25000x1500x 2200mm |

SLG85 | 200kw | 150kw | 400 -500kg /h | 30000x3500x 4300mm |

Double screw extruder Feature:

1. core filling snack food machine can take corn, rice, wheat, oat, rye and other grains as materials to produce extruded snacks, with crispy taste and lively shape.

2.Different shapes of snacks can be produced such as Round, triangle, square, stars, flower, etc

3.core filling snack food machine is from feeding, extruding, core filling, shaping ,cutting , oil spraying to finished products are done once time automatically.

4.This core filling snack food machine can produce all kinds of inflating foodstuffs, rice bread, core snacks, crackers, gruels, nutrient-flour, and baby food and so on.

5.The screws are made by ally steel and special craft, the screw life is longer, uses building block system structure, may combine willfully.

6.The forced lubrication system, by guaranteed equipment transmission longer life.

7.Visible auto-temperature controlling system, make the temperature-controlling to be more direct-viewing, parameter to be more precise.

8.It also can be designed according to customer requirement.

We Provide Satisfied Service & Turnkey Solution:

1.) Consultation service before, during,and after sales;

2.) Project planning and design service;

3.) Debugging of equipment until everything is functional;

4.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

5.) Training of equipment maintenance and operating personally;

6.) New production techniques and formulas;

7.) Provide 1 year complete warranty and life-time maintenance service.

Our Most Popular Snacks Food Production Line :

No. | Production Line |

1 | Extruded Kurkure / Nik Nak Snacks Food Production Line |

2 | Core Filling / Inflating Snacks Production Line |

3 | Breakfast Cereals / Corn Flakes Production Line |

4 | Extruded Doritos / Tortilla Corn Chips Snacks Food Production Line |

5 | Crispy Chips / Sala / Bugles Production Line |

6 | Nutrition Powder / Baby Rice Powder Production Line |

7 | Nutrition Rice / Artificial Rice Production Line |

8 | Bread Crumbs Production Line |

9 | Extruded Soya Meat Food Production Line |

10 | Extruded Pet / Dog / Cat Food Production Line |

11 | Chewing / Jam Center Pet Food Production Line |

12 | Extruded Snacks Pellet Food Production Line |

13 | Instant Noodles ProductionLine |

14 | Fried Wheat Flour Snacks Production Line |

| Model | Installed power | Real power | Output | Dimension |

| SLG65-III | 70kw | 40kw | 100-150kg/h | 22000x1200x2200mm |

| SLG70-III | 90kw | 50kw | 200-240kg/h | 25000x1500x2200mm |

| SLG85-III | 120kw | 100kw | 400-500kg/h | 30000x3500x4300mm |

| SLG90-III | 135kw | 100kw | 800-1000kg/h | 30000x3500x4300mm |

| SLG65-I | 50kw | 30kw | 60-80kg/h | 15000x1200x2200mm |