Gd50/Gd50q Small Hard Candy/ Jelly Candy Depositing Line

Shanghai Target Industry Co., Ltd.- Certification:CE, ISO9001

- Automatic Grade:Automatic

- Application:Ice Cream, Candy, Chocolate

- Customized:Customized

- Capacity:50kg,H

- Depositing Speed:45-55n,Min

Base Info

- Model NO.:GD50,GD50Q

- Electric Power:16kw,380V

- Total Length:6m

- Max Candy Weight:as Per as Candy Size

- Room Condition:Temp20~25°c

- Transport Package:Wooden Case

- Specification:CE, ISO9001

- Trademark:TGmachine

- Origin:China

- HS Code:84382000

- Production Capacity:50kg,H

Description

Basic Info.

Model NO. GD50/GD50Q Electric Power 16kw/380V Total Length 6m Max Candy Weight as Per as Candy Size Room Condition Temp20~25°c Transport Package Wooden Case Specification CE, ISO9001 Trademark TGmachine Origin China HS Code 84382000 Production Capacity 50kg/HProduct Description

GD50/GD50Q Small Hard Candy/ Jelly Candy Depositing Line

FEATURES:

This is the smallest productionline for gummy candy new designed compact gummy machine was made for a pharmacy company we realized this is a new available small commercial machine for new confactionery investors the whole production line at most 5 meters at length, so a room of 6m length is enough and only 100pcs moulds required for this line.

The processing line is an advanced and continuous plant for making different sizes of gelatin-type soft candies. It is an ideal equipment which can produce out good quality products with the saving of both the manpower and the space occupied.

TECHNICAL SPECIFICATIONS:

| Model | GD50Q |

| Production capacity ( kg/h) | 50 |

| Rated depositing times(n/min) | 25~55 |

| Electric power needed | 5kw/380V |

| Refrigerator | MT120 15,000 kcal/h |

| Compressed air consumption Compressed air pressure | 0.20m3/min 0.4-0.6 Mpa |

| Conditions needed for the cooling system: 1.Room temperature(ºC) 2.Humidity (%) | 20-25 55 |

| Length of the whole line (m) | 6 |

| Gross weight ( Kgs) | Approx.1000 |

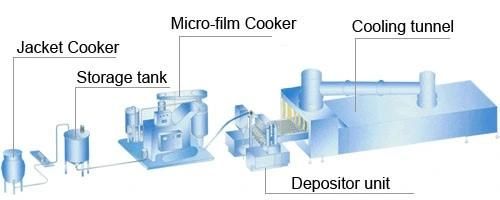

Deposited hard candy processing flowchart(As reference):

Raw material dissolving ->Transporting->Storage->Dosing->Pre-heating->

Micro-film cooking->Discharding->Mixing with favor and color-> Depositing->

Cooling->De-moulding-> Conveying->Packing->Final products

MAIN EQUIPMENT LIST:

The whole line is comprised of cookers, vacuum micro-film syrup cooking unit, depositor, industrial cooling system, gear pumps, dosing pumps, controller and etc.

PROCESS FLOWING LAYOUT CHART: