600L 6hl 5bbl Complete SUS304 Direct Fire Heating Two Vessel Brewhouse

Shandong Zunhuang Brewing Equipment Co., Ltd.- Condition:New

- Customized:Customized

- Voltage:Customized

- Composition:Brewing Equipment

- Processing Material:SUS304,316

- Transport Package:Wooden,Veneer Case for LCL, Plastic Film Wrapped

Base Info

- Production Capacity:500PCS,Year

- Origin:China

Description

Basic Info.

Origin China Production Capacity 500PCS/YearProduct Description

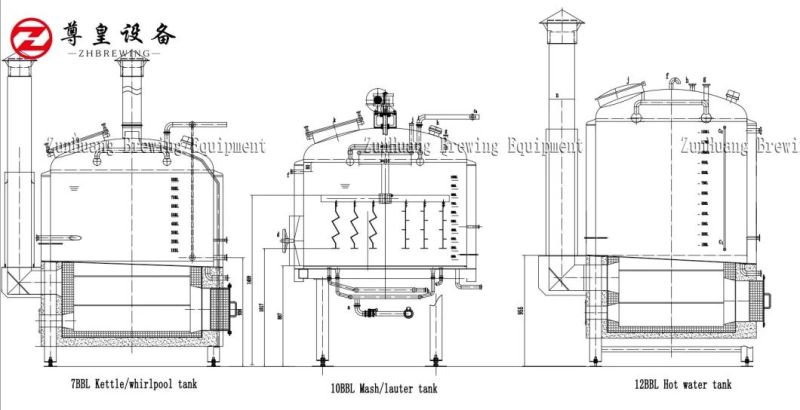

America 7BBL Direct Fire Equipment.

The configuration is 10BBL Mash tun&Lauter tank, 7BBL Brew kettle&Whirlpool, 12BBL Hot Water Tank, 15BBL Cold water tank, 15m2 Plate Heat Exchanger, 7BBL fermenter tank and BBT, 60 gallon glycol tank and 8HP chiller, pump and other necessary.

The brewery is located in pensacola, a coastal city in Florida.Known as the "sunshine state", Florida in the United States is world-famous for its brilliant sunshine and unparalleled beaches. Plenty of options in brewery including beer, Wine, Cider, Mead, Hard Seltzer, Hard Tea, Food, and Appetizers. All of the brewery beers are made in house using premium ingredients and advanced brewing techniques. Welcome!

Mash system details:

10BBL Mash/lauter tun:

Mash heating mode: Hot water is warming up

7BBL Kettle/Whirlpool tun:

The lower part of the tank is equipped with a combustion chamber

12BBL Hot water tank

7BBL fermenters and bright beer tank:

The cooling Jackets of fermenting tanks adopts dimple plate, arch channels .

the inner surface of the liner shall be pickled and passivated.

Welding by argon arc welding.

After production, hydraulic test of cylinder and jackets.

Cooling system:

15BBL Cold water tank:

Dimple cooling jacket cooling

60-gallon glycol tank:

Customized according to customer requirements.

CIP system:

Movable directional wheel design.

The inner surface of the liner shall be pickled and passivated.

With insulation.

With Electric heat pipe

Customer inspection process:

After the production of the equipment is completed, the customer comes to the factory to inspect the equipment, check the overall production of the equipment, the voltage of the auxiliary machine, etc., and the customer is satisfied.

Customer installation and use status