Spiral Conveyor for Breads Cooling System

Shandong Kenside Machinery Manufacturing Co., Ltd.- Usage:Biscuit, Cake, Pizza, Bread

- Power Source:Electric

- Timing Device:With Timing Device

- Type:Cooling Conveyor

- Voltage:Customized

- Customized:Customized

Base Info

- Model NO.:KSD-2598

- Belt Width:152 - 1500mm

- Wire Diameter:1.2 , 1.4 , 1.6 , 2.0 mm

- Rod Pitch:19.05 , 25.4 27.43 , 30 , 38.1 mm or Customized

- Belt Material:Stainless Steel or Plastic

- Side Guard:Available

- Work Temperature:-50 - 100c

- Dimensions:Customized

- Rod Diameter:5 , 6 mm

- Overseas Installation:Available

- Applications:Bread, Biscuit, Flour-Made Dishes, Meat, etc

- Transport Package:Wooden Box with Waterproof Film

- Specification:customized

- Trademark:KENSIDE

- Origin:China

- HS Code:84283900

- Production Capacity:10 Sets Per Month

Description

Basic Info.

Model NO. KSD-2598 Belt Width 152 - 1500mm Wire Diameter 1.2 / 1.4 / 1.6 / 2.0 mm Rod Pitch 19.05 / 25.4 27.43 / 30 / 38.1 mm or Customized Belt Material Stainless Steel or Plastic Side Guard Available Work Temperature -50 - 100c Dimensions Customized Rod Diameter 5 / 6 mm Overseas Installation Available Applications Bread, Biscuit, Flour-Made Dishes, Meat, etc Transport Package Wooden Box with Waterproof Film Specification customized Trademark KENSIDE Origin China HS Code 84283900 Production Capacity 10 Sets Per MonthProduct Description

Spiral Conveyor for Breads Cooling System1. Model : SPIRAL COOLING CONVEYOR

2. Application : Spiral cooling tower is designed for cooling baked food which just come out of oven from high temperature to right temperature, it's suitable for cooling baked food, such as bread, hamburger, toast, moon cake, etc

3. Feature:

(1). Natural cooling keep the bread's natural taste and aroma.

(2). Framework is high quality stainless steel, ensure stability of spiral cooling tower.

(3). The conveying belt with mesh is made of high strength stainless steel.

(4). Internal structure of spiral cooling tower is more convenient to servicing.

(5). Spiral cooling tower entry/exit configuration options permit most efficient use of available plant space.

(6). Installation of spiral conveyor has enough flexibility, it possible to configure plant of any kind and for any type of

need, that are perfectly adaptable to any already existent production line.

(7). Cleaning job made simple. The conveyor belt made entirely out of stainless steel and the special constructional

system, that allows the user to reach easily every part of the spiral, make it possible to achieve the high hygiene and health standards required by the food industry

Quick Specifications:

| Material | All Stainless Steel 304 or 316 |

| Belt Width | 152 - 1500 mm |

| Belt Material | stainless steel or plastic spiral belt |

| Spiral Pitch | 5 - 30 mm or customized |

| Wire Diameter | 1.0/1.2/1.4/1.5/1.6/1.8/1.8/2.0 mm |

| Rod Pitch | 19.05/25.4/27.43/30/30.5/31.75/35.5/38.1/50.8 mm |

| Rod Diameter | 5/6/7 mm |

| Mesh Overlay Styles | Standard Balanced Weave / Unilateral Weave |

| Turn Radius | 1.1/1.6/1.7/2.2 or customized |

| Side Guard | With / Without |

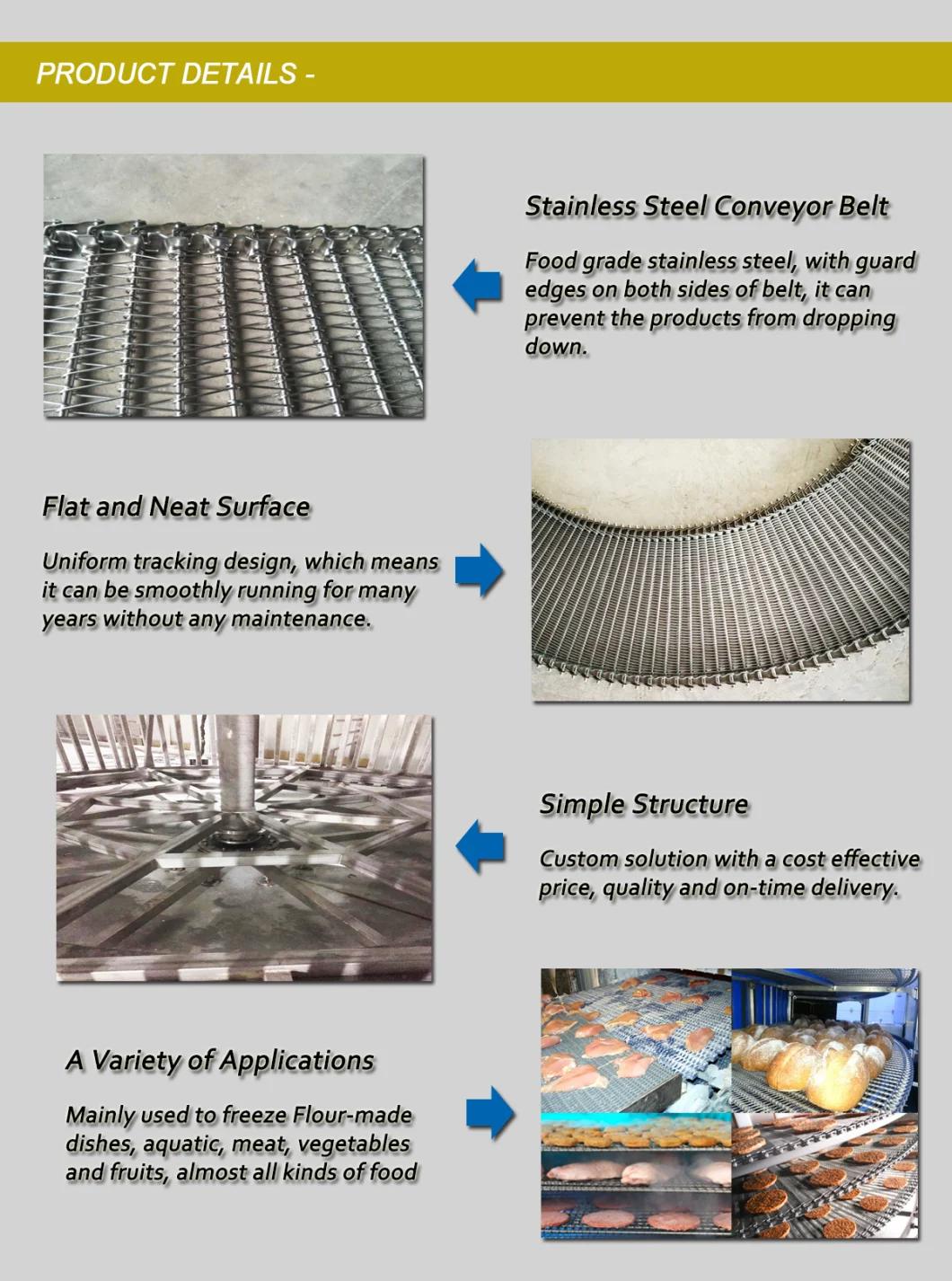

Product Details:

Benefits:

1. Wide applications: Flour-made dishes, aquatic, meat, vegetables and fruits, almost all kinds of food.

2. High strength food grade SUS304 stainless steel spiral belt, with side guards at both sides, prevent the products from falling down.

3. Tension device of spiral belt adopts floating shaft, which can automatically adjust the tightness of the mesh belt and ensure the smooth and reliable operation of the mesh belt when the temperature changes or the force changes.

4. All stainless steel frame, sanitary hygiene, reasonable structure, easy to clean.

5. Non-toxic, tasteless, wear-resistant polymer polyethylene (molecular of more than 4 million) material, which can ensure the whole machine long service life and healthy safety.

6. Low temperature special gear reducer motor, stable and reliable transmission system, multiple alarm control points to ensure smooth operation of the whole machine.

7. Custom design of various specifications and varieties of 250-5000KG/H, and we can also make special designs according to the requirements of customers.

8. Main electrical components are well-known brand, inverter stepless speed regulation technology, PLC electric control system, clearly visible fault display and habit preference storage function.

Product Pictures:

Our Plant:

Company Information:

Founded in 2001, Shandong Kenside Machinery Manufacturing Co., Ltd. is located at town of metal conveyor belt - Shandong, China. With workshop covers an area of more than 16, 000 square meters, it specialise in R&D, design, production and sale of all kinds conveyor belts and chains. There are more than 10 engineers and 120 employees and workers at our factory now.

Our main products are as followings: Chain driven belts, chain plate belts, roller conveyor, spiral belts, flat wire belts, flat flex belts, eye link belts, sprockets, etc. We can also design, produce and OEM all kinds of conveyors according to your requirements.

"Good Quality, Best Service" is our principle, welcome friends from all over the world to visit and enquiry.

Contact Information: