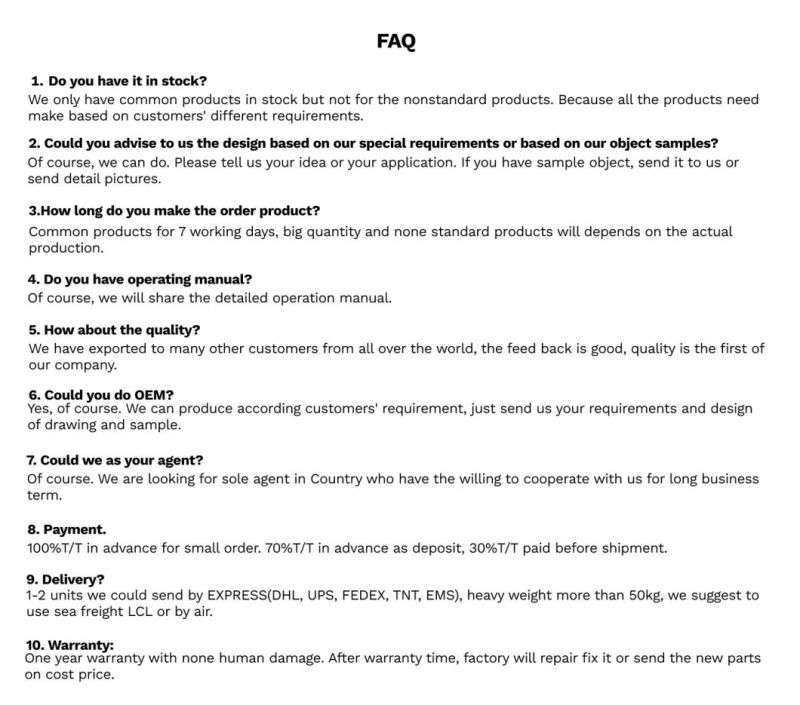

20KHz Ultrasonic Food Cutter With Food Grade Titanium Material Blade

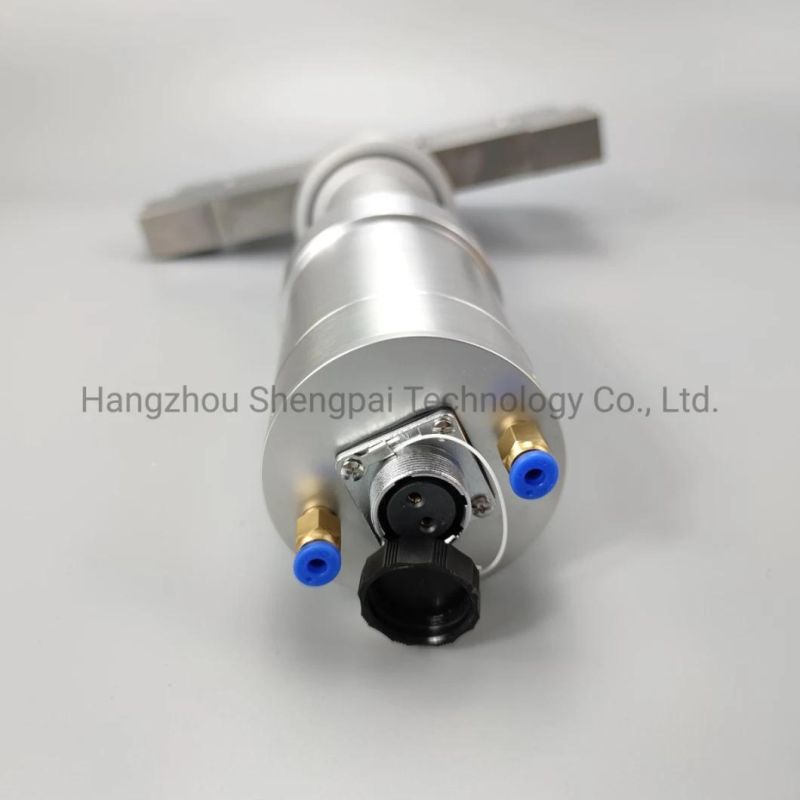

Hangzhou Shengpai Technology Co., Ltd.- Warranty:One Year

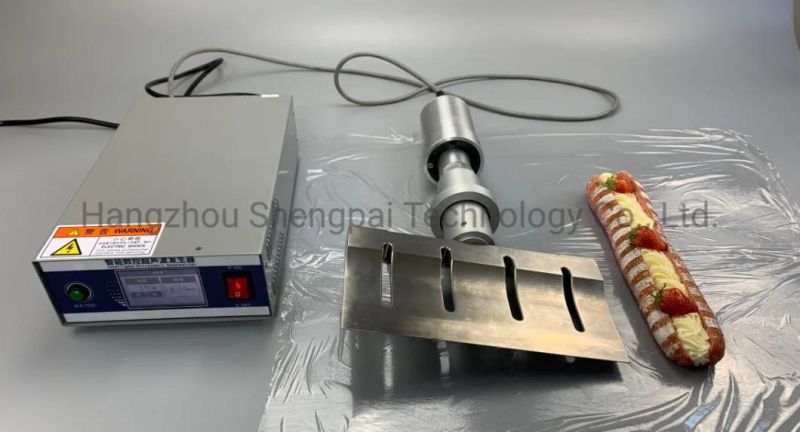

- Material of Blade:Titanium Alloy

- Frequency:20kHz

- Power:500W-2000W

- Model No:SPC20-255

- Applcation:Ultrasonic Food Cutting

Base Info

- Model NO.:SPC20-255

- Blade Height:128mm

- Blade Width:255mm

- Cutting Thickness:1-110mm

- Transport Package:Carton, Wooden Case

- Trademark:SP

- Origin:China

- HS Code:8543709990

- Production Capacity:1000pieces,Month

Description

To solve the ordinary stainless steel cutter when cutting a cake problems, SPsonic developed ultrasonic food cutting equipment to solve the stick blade and perfect color mixing problem. Ultrasonic food cutting expe-riment is the role of ultrasound energy to the knife, high-frequency vibration in the ultrasonic knife between the cake and the establishment of a little surface friction, so there will be no sticky knife and mixing problems. The ultrasonic food cutting equipment for automated production lines, without having to stop the knife clean, not only increase productivity, reduce scrap rates cake, but also greatly reduces the cost of production.

Specification:

Applications:

- Cakes and Pies

- Dough of cookies

- Snacks and health bars includes dried fruits.

- Pizza and quiche

- Various cheeses and butter

- Processed meet

- Ice cream

- Fresh and dried vegetables

- Candy

- Nougat

Product Advantage:

1. Ultrasonic processing is an efficient way to cut, slice, divert, align or transfer a variety of products.It involves a vibrating blade producing a nearly frictionless surface with the influence of ultrasonic which does not deform products and to which they do not stick. The vibrating frictionless blade cuts or slits products cleanly such as nuts, raisins, dried fruit or chocolate morsels without displacement or plowing.

2.Ultrasonic vibration reduces friction resistance between the blade and mterial, and it makes the blade cut smoothly without deformation.The cutting blade is made of titanium (or the material according to your requirement ). It is completely inert and enduring material.

3.The use of ultrasonic cutting , incision aesthetic integrity, trimming neatly smooth, without Burr, to leave the border areas, not black, not burned, not the hardware products to feel very good shear results