1000 Liter Malt Equipment Stainless Steel Tank Brewing Equipment Beer

Shandong Zunhuang Brewing Equipment Co., Ltd.- Condition:New

- Customized:Customized

- Voltage:380V

- Composition:SS304

- Processing Material:Beer

- Process:Boiling

Base Info

- Model NO.:ZH-1000L

- Material:SS304

- Heating:Gas Steam Generator

- Tank Thickness:Inner 3mm Outside :2mm

- Shape:Cylinder and Cone

- Heating Method:Electricity,Gas,Steam,LPG

- Control Method:PLC,Dcs

- Capacity:100-3000L

- Insulation Thickness:50,80,100mm

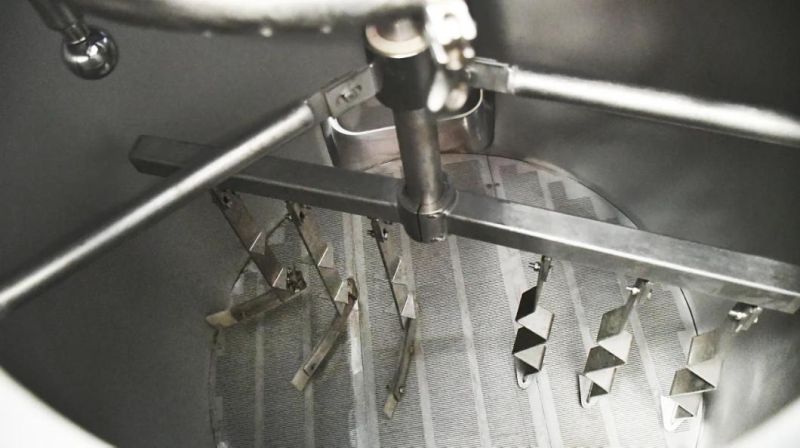

- CIP Cleaning Ball:Tri-Clamp 63,76,89

- Conical Degree:60 Degree to 90 Degree

- Keywords:Beer Brewing Equipment

- Transport Package:Steel Frame or Wooden Case

- Specification:as customer request

- Trademark:Zunhuang

- Origin:China

- Production Capacity:500piece

Description

Basic Info.

Model NO. ZH-1000L Material SS304 Heating Gas Steam Generator Tank Thickness Inner 3mm Outside :2mm Shape Cylinder and Cone Heating Method Electricity/Gas/Steam/LPG Control Method PLC/Dcs Capacity 100-3000L Insulation Thickness 50/80/100mm CIP Cleaning Ball Tri-Clamp 63/76/89 Conical Degree 60 Degree to 90 Degree Keywords Beer Brewing Equipment Transport Package Steel Frame or Wooden Case Specification as customer request Trademark Zunhuang Origin China Production Capacity 500pieceProduct Description

Beer brewing equipmentApplications area: Beer Bars, Hotels, Restaurants, Beer pub, Micro Brewery, Beer Plant&Factory etc.

Product features:

1. Appearance clean and generous: The tank is pickling passivation, and the equipment is bright;

2. Good insulation effect: The equipment is divided into two kinds of heat insulation and cold insulation, which is the best to ensure the temperature of the beer brewing process;

3. Low energy consumption: environmental protection, energy saving, low power consumption, saving energy consumption of about 20%;

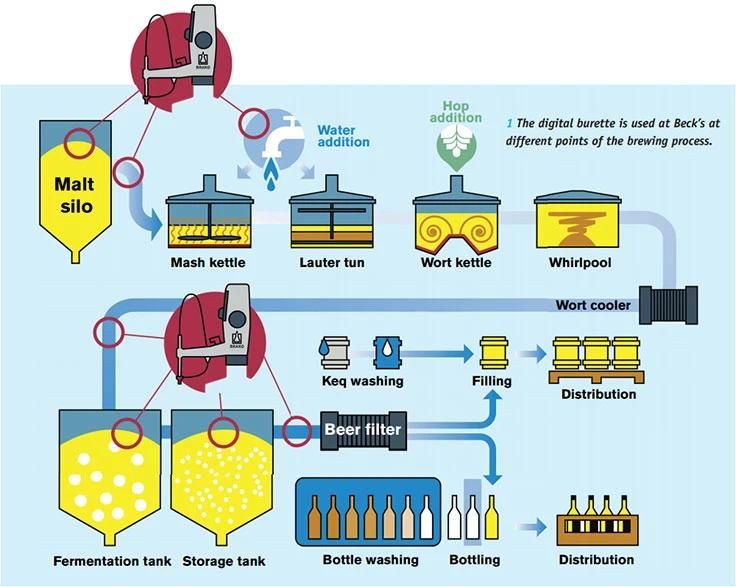

Beer equipment list

| 1 | malt milling system | malt miller machine grist case |

| 2 | Mash system | Mash tun/Brew kettle Lauter/whirlpool tank (Or mash tun/lauter and brew kettle whirlpool) Hot water tank(optional) Mash/wort/hot water pump Motors Wort oxygenation device Operation platform Plate heat exchanger |

| 3 | Fermenting system | Beer fermenters Bright beer tanks Yeast adding tank Accessories, such as sample valve, pressure gauge, safety valve and so on |

| 4 | Cooling system | Glycol tank Refrigerating unit Glycol pump |

| 5 | CIP cleaning system | disinfection tank & alkali tank &cleaning pump etc. |

| 6 | Controller | Control system, we have PLC automatic and semi-automatic, the elements brand include LG, Siemens and so on. |

| 7 | Kegging system | kegging system ( keg washer and keg filler machine), the control system brand is Siemens. |

Zunhuang series mash system consist of 1 vessel mash system, 2 vessels mash system, 3 vessels and other design, mainly includes mash tank, brew kettle, lauter tank and whirlpool.

Fermentation System

Fermentation SystemFermenter cooling method is cooling dribbling with standard parameters, layout and control mode in domestic. Zunhuang companies design and manufacture cooling dribbling according to 0.4-0.5 meters per cubic meter cooling area. And the fermentation tank adopt two-stage cooling refrigerant control mode at the end of the cone and the tank level 10--15cm down.