Stainless Steel 30cm Super Long French Fries Makers French Chips Press Extruder

Shenzhen Delphi Technology Limited- After-sales Service:Free Spare Part

- Warranty:12months

- Certification:CE

- Power Source:Manual

- Process:Manual

- Automatic Grade:Manual

Base Info

- Model NO.:LY-885

- Application:Chips, Fries

- Customized:Customized

- Transport Package:Carton

- Specification:45*26*20cm

- Trademark:ZA

- Origin:China

- HS Code:8210000000

- Production Capacity:90000sets,M

Description

Basic Info.

Model NO. LY-885 Application Chips, Fries Customized Customized Transport Package Carton Specification 45*26*20cm Trademark ZA Origin China HS Code 8210000000 Production Capacity 90000sets/MProduct Description

Snack Machine Taiwan Super Long Potato Chips Extruder Ultra Long French Fries Press Extruder Machine

Advantage

1 Manual work ,excellent Technique with fashion design.

2. High Quality with competitive price and timely delivery

3. Suit for indoor and outdoor use

4. Good one-line service

Features

1. Labor Saving

2. Time Saving (once peeled can chop an onion in less than 5 seconds)

3. Consistent cut size for portion control

4. Customization service offered

Saftey Instructions

Remember that the blades are VERY SHARP,be carful when handing and operationg the machine to keep hands away from the cutting edges.

To clean

1.Remove the PUSHER assembly,BUMPERS and BLADE AND HOLDER ASSEMBLY off the GUIDE RODS.

2.Thorougly wash the PUSHER assembly,the BLADE ASSEMBLY,and the FRAME.

3.The PUSH BLOCK can be removed from the PUSH BLOCK GUIDE by removing THUMBSCREWS for further cleaning.

4.The chopping BLADE AND HOLDER ASSEMBLY my also be totally disassembled for furniture cleaning as follows:

a) Remove the SCREWS and the BLANDE HOLDER PLATE.

b)Gently tap the BLADES and the BLADE SPACERS from the BLADE HOLDER.

5 To Reassemble:

a)Place the BLADE HOLDER on a table top with the BLADE SPACER pockets upward.

b)Insert the 4 BLADE SPACERS with their slots toward the inner opening of BLADE HOLDER.

c)Insert BLANDES with sharp edge downward and slots upward.

d)Insert BLANDES with sharp edge and slots downward.

e)Reposition the BLADE HOLDER PLATE and secure with SCREWS

Material

1.Cast aluminum frame,stainless steel blade

Packing:

Export Carton.

Customization

1. Shipping Mark

2. Hangtag and Logo

3. External Artwork

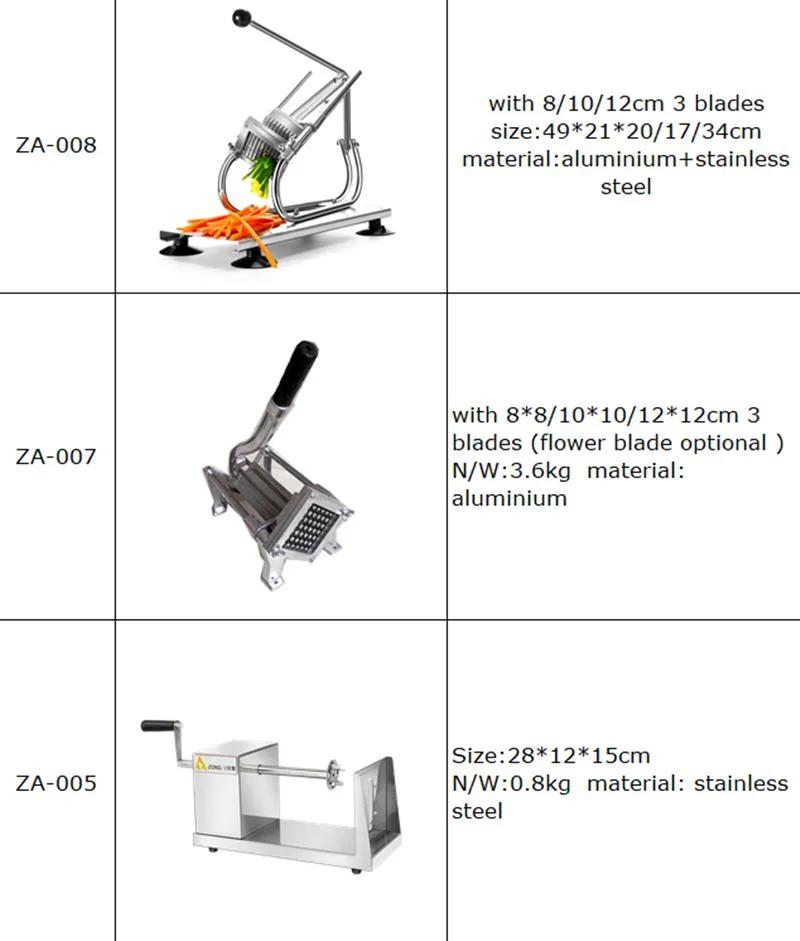

More related products for optional :

• 1 Where is your factory?

• guangdong Province, China

• 2 What is your machine warranty?

• 1 year, main parts warranty time will be 1 years.

• 3 Do you supply spare parts?

• Yes, we supply spare parts with reasonable price;

• 4 What can you provide for after sale service?

• on line support ,video support and We can send engineers to your factory for installation and training if customers' required.

• 5 If we show you our layout of factory, can you help to design the whole process line?

• Yes, our experienced engineers and technical employee can help you to arrange the layout and installation of whole process line based on your real situation;

• 6 How can we contact you if we meet problems during production?

• Phone/email/wechat/whatsapp/Skype are all available.

• 7 If we have samples of new products, can you help to analysis and design the machine?

• Yes, Our technical department can help to analysis, design and test the new products you offered.

Packaging & Shipping

• All Machine will be cleaned and whole wraped by plastic film to avoid any scratch;

• Extra Spare Parts,wires and tool box will be placed with the package;

• Delivery Department and sales will check the list to avoid any missing;

• All standard export carton packing for protecting the machine during long-time shipment;