Puffed Corn Snack Twin Screw Food Extruder

Jinan Datong Machinery Co., Ltd.- Certification:CE, ISO9001

- Power Source:Electric

- Process:Mild Processing

- Automatic Grade:Automatic

- Application:Candy, Chips

- Customized:Customized

Base Info

- Model NO.:SLG85

- Material:Stainless Steel

- Motro Brand:Siemens Motor

- Inverter:Delta Brand

- Size:15.0*5.0.*5.0

- Snacks Raw Material:Corn Wheat Flour, Rice Flour......

- Electric Parts:LG, FUJI, Omron etc

- Snacks Material:Corn Flour, Rice Flour, Wheat Flour

- Whatsapp:0086-15264102980

- Website:Www.Dotomachine.COM

- Certificate:ISO Ce

- Transport Package:Woodcase

- Trademark:Jinan Datong Machinery Company

- Origin:Jinan

- HS Code:84361000

- Production Capacity:200-500kg,H

Description

Basic Info.

Model NO. SLG85 Material Stainless Steel Motro Brand Siemens Motor Inverter Delta Brand Size 15.0*5.0.*5.0 Snacks Raw Material Corn Wheat Flour, Rice Flour...... Electric Parts LG, FUJI, Omron etc Snacks Material Corn Flour, Rice Flour, Wheat Flour Whatsapp 0086-15264102980 Website Www.Dotomachine.COM Certificate ISO Ce Transport Package Woodcase Trademark Jinan Datong Machinery Company Origin Jinan HS Code 84361000 Production Capacity 200-500kg/HProduct Description

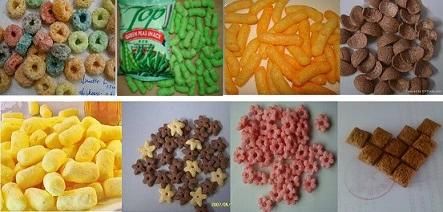

1. Description of Cheese balls snacks food machine:Cheese Curls Food Extruder Machinery adopt corn, rice, wheat, oat, barley etc as ingredients to make puffed snack. Through friction of screw and barrel, the grains are cooked in the extruder. Forming is at the die face cutter. The product shape is determined by a combination of the die aperture, including ball, tube, stick, ring, fruit loop, star, wheel and flower etc.

2. Snacks Raw materials:

Corn, rice, millets, wheat, oat, barley etc as ingredients. Please note that all the materials should be in powder(flour) or grits form.

3. Snacks food Products shapes:

Variety shapes are available for ball, tube, stick, ring, fruit loop, star, wheel and flower and heart shape by adjusting the mould in the extruder

4. Corn snack food line Capacity:

60-80kg/h 100-150kg/h, 200-240kg/h, 500kg/h

| Model | Installed power | Real power | Output | Dimension |

| SLG65-III | 70kw | 40kw | 100-150kg/h | 22000x1200x2200mm |

| SLG70-III | 90kw | 50kw | 200-240kg/h | 25000x1500x2200mm |

| SLG85-III | 120kw | 100kw | 400-500kg/h | 30000x3500x4300mm |

| SLG90-III | 135kw | 100kw | 800-1000kg/h | 30000x3500x4300mm |

| SLG65-I | 50kw | 30kw | 60-80kg/h | 15000x1200x2200mm |

Grain grinder---Mixing system---Twin screw Extrusion system----Drying system----Flavoring system--Packing system

6. China standard industrial Voltage for the machine:

Three phases: 380V/50Hz, Single phase: 220V/50Hz, We can make it according to customers' Local voltage according to different countries (400v 415v 480v...).

7. Sancks food Machines Materials:

All the Snacks food machines are made by stainless steel, this whole line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function.

8. Details & Features of Cheese balls snacks food machine:

1. Alloy (38CrMoAL) screw made by nitriding process, high strength and wear-resting. Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials.

2. Adopting speed-adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine, stable materials feeding in the whole food process.

3. Gearbox with automatic lubrication function, extending gear life.

4. Increased radiator on driving part for forced cooling effect, ensuring extruder operates safely.

5. Barrel with water-cooled circulation, raw materials not only for corn/rice, also for wheat flour/starch with high viscosity. Different moisture-extrusion temperature ratio, whole-expanded and half expanded as different type of products.

6. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

7.Packaging & Shipping for Snacks Machine:

Packing: inside plastic bag, outside wooden case for Snacks Machine(Based on the customers' need adopt the wooden case or wooden pellets, etc.).

Transportation: shipping, train, express or upon clients' demands.

8.Company details:

Professional Service for Snacks Machine:

1. Free consultation service before, during, and after sales;

2. Free Project planning and design services upon clients' special demands;

3. Debugging and inspecting of equipment until everything is functional before leaving the factory;

4. Overseas installation and training of equipment maintenance and operating personally;

5. Provide basic production techniques and formulas;

6. 1 year complete warranty for Snacks Machine.

1. Corn Snacks machine

2. Corn snacks machine

3. Puffed snack food machine

4. Snack food processing line

5. Cheese balll machine

6. Cheese curls processing line

7. Inflating snacks processing line

8. Leisure inflating food machine

9. Crispy snack food making machine

10. Core-filling snack food machine