Electric Maize Wheat Corn Flour Roller Grinding Wheat Flour Mill Milling Machine

Henan Chengli Grain and Oil Machinery Co., Ltd.- Type:Flour Mill

- Application:Wheat

- Voltage:380V

- Appearance:Vertical

- Press Materials:Wheat

- Press Series:Second

Base Info

- Condition:New

- Customized:Customized

- Transport Package:Wooden Box or Container

- Trademark:Chengli brand

- Origin:Henan Province. China

- Production Capacity:50set,Month

Description

Basic Info.

Condition New Customized Customized Transport Package Wooden Box or Container Trademark Chengli brand Origin Henan Province. China Production Capacity 50set/MonthProduct Description

Description of wheat milling plant :

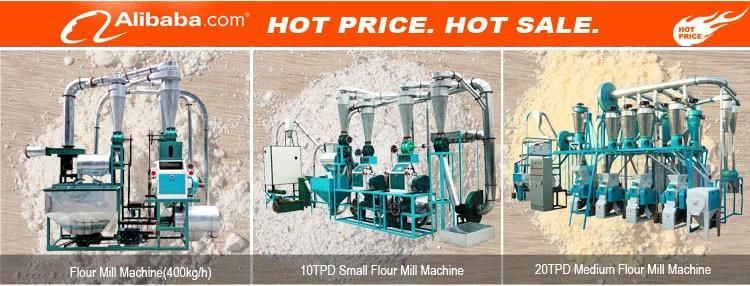

Our products including the whole line of wheat/maize flour equipments, conveyor equipments, storage equipments, and the singlemachines of them. We can supply the COMPLETE LINE OF WHEAT/MAIZE FLOUR MILLING PLANTof 5-500T PER DAY, including the engineering

design and installation.

2.Process of wheat milling plant :

1.Cleaning part: Beating-->Screening-->Destoner-->Magnetic separator--> Dampening

2.Flour making part: Milling --> Sifting

3.Packing Part: The packing part can be manual one also can be auto one, this can be designed according to requirement and machine

Wheat flour milling machine flour powder making machine for wheat .

1. Cleaning part this part is to remove the middle and small impurities from the raw wheat such as, dust, stone, magnetic material, rotten wheat and so on. This part consists of beating, screening, de-stoner, magnetic separator and dampening. This section is to prepare for milling part and to protect the machinery as well. 2. Milling and sieving part The second step, to mill the grain (wheat, corn, maize) into flour and separate the flour from bran and other by-product to get the most fineness wheat flour. (1) Mill: grinding the grain(wheat, corn) to break the integrity by the moving roller (2) Sifter: with different size of the mesh, it can separate the flour, bran and other by-product, also separate large size and small size to ensure flour quality. 3.Packaging part The third step, it can pack the end product(wheat ,maize flour) automatically and quantitatively, which can save labor a lot.

Henan chengli grain and oil machinery co ., ltd

Henan Chengli Grain And Oil Machinery Co., Ltd is an integrated modern company of project design, machinery manufacture, marketing and after-sales services in grain processing industry, mainly the corn/maize flour and grits milling, rice polishing, wheat flour milling, etc. Based on the strong technical force, high product development capability, advanced machinery manufacturing facility, scientific management and excellent after-sales services, Chengli brand is quite famous in China and some overseas countries and regions.

Wheat Maize Corn Flour Milling Mill