Fiji Water Packing Machine with High Speed Color Film Wrapping

LangFang YongChuang Packaging Machinery Co., Ltd.- After-sales Service:7*11, Oversea Service Available

- Warranty:1 Year

- Processing Material:Animal Raw Materials, Forest Products, Special Agricultural Products, Garden Products, Agronomic Products, Natural Ingredients

- Application:Pet Food, Chocolate, Ice Cream, Vegetable, Fruit, Dairy, Beverage

- Customized:Customized

- Certification:CE, ISO9001

Base Info

- Model NO.:LC-MBS35

- Power Source:Electric

- Automatic Grade:Automatic

- APP:Water Juice Beverage Beer

- Transport Package:Standard Export Packaging

- Specification:Machine Size L16270*1600*2500mm

- Trademark:Young Chance Pack

- Origin:China

- HS Code:8422400000

- Production Capacity:1pieces,Month

Description

Containers and specificationsProject Name: Full Automatic Complete Mineral Water 2000-20000bph Production Line PH≥4.6drinking water material shape Filling volume(ml) Filling level(mm) Neck type PET Bottle Square or Round Bottle 100-2000ml Distance from bottle neck

According request As request Adjustable specifications of the bottle type Middle Mould Base: Bottle diameter ≤105mm Bottle Height≤335mm Customers need to buy additional change-over parts for the different bottles.

If using square bottles, then bottle separating system will be added. Container Label & Control Mode Packaging system Palletizing system Hot Melt Roll-Fed

PVC Shrink Label

Full Label/ Half Label

Manual / Automatic Packing system Min, Spec. Manual

Low position gantry palletizer

Robot Palletizer

High position gantry palletizer

Single Arm Palletizer

Manual Palletizer Manual

Film shrinker

Wrap Around packer

Robert Packing Machine 1*2

2*3

3*4

4*6

3*5 User Ambient Conditions: Temperature:10~40ºC;Humidity:No dew User Electrical Supply Specification Voltage:380V±5%, 3phase; Frequency:50HZ±1%

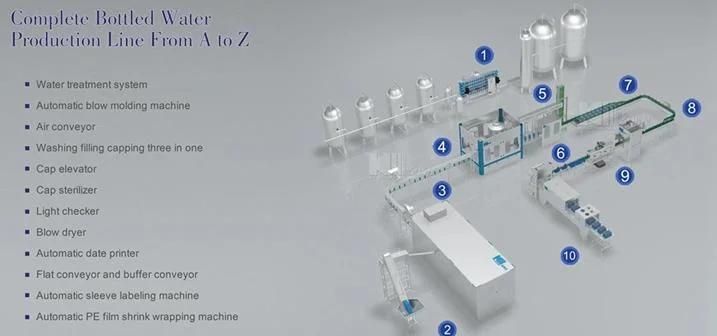

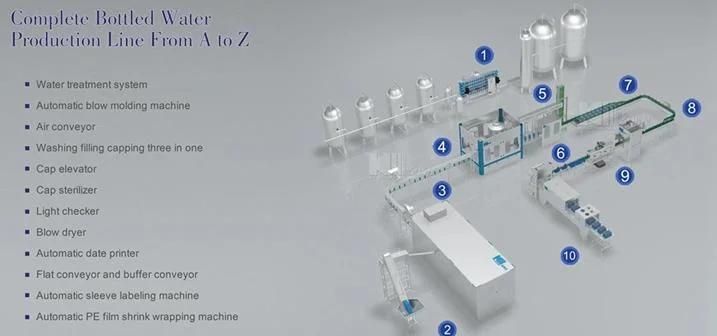

We provide the Complete plant turnkey project for pure water production line including:

1.Water Treatment System, (Water Filtration)

2.Bottle Blowing Machine,(Making plastic bottles)

3.Air Conveyor,(Transport empty bottles)

4.Water Filling Machine ,(Filling water into bottles)

5.Cap elevator, (Transport cap)

6.Blow dryer, (Blow dry water)

7.Flat Convey, (Transport bottle)

8.Code Sprayer,(Printing the date on the bottle water)

9.Labeling Machine ,(Labeling in bottled water)

10.Bottle Shrink Wrapping Machine, (package the bottle water)

11.injection molding machines,(for pet preform)

It is suitable for producing PET plastic bottles from: 250-2000ml;

Both round bottle and square bottle are available.

Material: PET Preform, Cap, Raw Water, PVC Label, Roll PE film

Bottling Line for Natural Mineral Drinking Water, Pure Water, Spring Water.

Flow chart :

Automatic bottle blowing machine --> Air conveyor system-->Washing,filling ,capping 3in1 machine-->Conveyor system-->Automatic sleeve labeling machine-->Automatic film shrink packing machine/Carton packing machine

Brief IntroductionMachine Dimension 16270×1600×2500 mm Shrinkage Tunnel Dimension 2500×700×450 mm Packaging Speed 33-35 Packs/Minute

Voltage/Power: 380V /55KW

Working Air Pressure: 0.6-0.8 Mpa

Air Consumption: 0.3 m3/minute Packaging Form:One piece heat shrink film wrappingPackaging Material : LDP

Special solutions for Printed Shrink Film(with designed Logo& company information) Wrapping.

Specail solution for Auto Cardboard Sheet Placing+ Auto Shrink Film Wrapping. Special solution for Auto Cardboard Tray Folding + Auto Shrink Film Wrapping.

Order Information

To help us make sure this model is suitable for you, please kindly provide the following information with your inquiry:

1) Details of your product (Dimensions, Photos and Drawings)

2) Packaging Combination for each pack (2×3, 3×4, 4×6 or others)

3) Packaging Capacity Required (How many bottles/cans for each hour on the current/planned production line)

4) Packaging Expectation (Photo of packed product shall be very helpful)

5) Packaging Automation Level (Semi-automatic or Complete Automatic)

6) The Layout Drawing of workshop (Optional, just help us prepare arrangement of the machine)

7) The Height of current production line (Optional, just help us confirm the height of conveying system)8) Other usful information which might helpful.

According request

If using square bottles, then bottle separating system will be added.

PVC Shrink Label

Full Label/ Half Label

Manual / Automatic

Low position gantry palletizer

Robot Palletizer

High position gantry palletizer

Single Arm Palletizer

Manual Palletizer

Film shrinker

Wrap Around packer

Robert Packing Machine

2*3

3*4

4*6

3*5

We provide the Complete plant turnkey project for pure water production line including:

1.Water Treatment System, (Water Filtration)

2.Bottle Blowing Machine,(Making plastic bottles)

3.Air Conveyor,(Transport empty bottles)

4.Water Filling Machine ,(Filling water into bottles)

5.Cap elevator, (Transport cap)

6.Blow dryer, (Blow dry water)

7.Flat Convey, (Transport bottle)

8.Code Sprayer,(Printing the date on the bottle water)

9.Labeling Machine ,(Labeling in bottled water)

10.Bottle Shrink Wrapping Machine, (package the bottle water)

11.injection molding machines,(for pet preform)

It is suitable for producing PET plastic bottles from: 250-2000ml;

Both round bottle and square bottle are available.

Material: PET Preform, Cap, Raw Water, PVC Label, Roll PE film

Bottling Line for Natural Mineral Drinking Water, Pure Water, Spring Water.

Flow chart :

Automatic bottle blowing machine --> Air conveyor system-->Washing,filling ,capping 3in1 machine-->Conveyor system-->Automatic sleeve labeling machine-->Automatic film shrink packing machine/Carton packing machine

Brief Introduction

Voltage/Power: 380V /55KW

Working Air Pressure: 0.6-0.8 Mpa

Air Consumption: 0.3 m3/minute Packaging Form:One piece heat shrink film wrappingPackaging Material : LDP

Special solutions for Printed Shrink Film(with designed Logo& company information) Wrapping.

Specail solution for Auto Cardboard Sheet Placing+ Auto Shrink Film Wrapping. Special solution for Auto Cardboard Tray Folding + Auto Shrink Film Wrapping.

Order Information

To help us make sure this model is suitable for you, please kindly provide the following information with your inquiry:

1) Details of your product (Dimensions, Photos and Drawings)

2) Packaging Combination for each pack (2×3, 3×4, 4×6 or others)

3) Packaging Capacity Required (How many bottles/cans for each hour on the current/planned production line)

4) Packaging Expectation (Photo of packed product shall be very helpful)

5) Packaging Automation Level (Semi-automatic or Complete Automatic)

6) The Layout Drawing of workshop (Optional, just help us prepare arrangement of the machine)

7) The Height of current production line (Optional, just help us confirm the height of conveying system)8) Other usful information which might helpful.