Acme Hot Sale Margarine Making Machine

Wuhan Acme Agro Tech Co., Ltd.- Certification:ISO9001

- Power Source:Electric

- Process:Frozen and Chilled

- Automatic Grade:Semi-Automatic

- Application:Food

- Customized:Customized

Base Info

- Model NO.:AM100

- Product Capacity:1200kg,H

- Power:36kw

- Normal Operating Pressure:2.5MPa

- Raw Material:Palm Oil

- Use:Margarine

- Operation:Easy

- Certificate:Ce ISO TUV

- Weight:25000kg

- Dimension:3500X1700X1350

- Transport Package:Plywood Box or as Clients Request

- Trademark:ACME

- Origin:Chian

- Production Capacity:2 Sets , Month

Description

Basic Info.

Model NO. AM100 Product Capacity 1200kg/H Power 36kw Normal Operating Pressure 2.5MPa Raw Material Palm Oil Use Margarine Operation Easy Certificate Ce ISO TUV Weight 25000kg Dimension 3500X1700X1350 Transport Package Plywood Box or as Clients Request Trademark ACME Origin Chian Production Capacity 2 Sets / MonthProduct Description

Detailed Images:

Product Description:

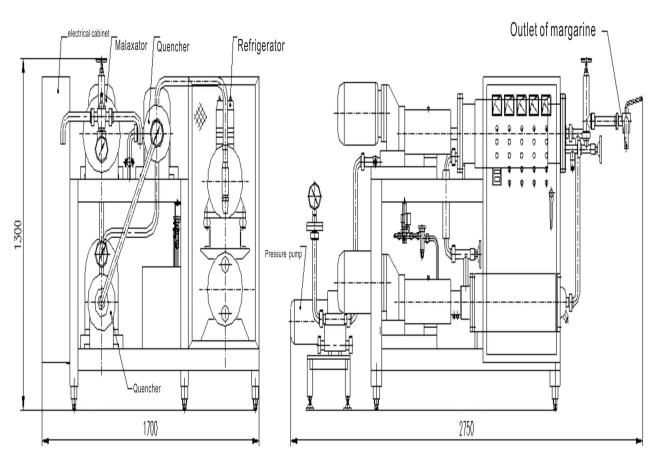

Margarine equipment is the hot equipment for producing fat products( Margarine, pastry margarine, etc.).The whole set consists of quencher, malaxator, hot water circulation system, cooling system, pressure delivery pump and so on.

The equipment's structure is tight, It covers a small area, operates simple, and saves work force.The mainparts of the machine are made of stainless steel which makes it corrosion resisting.Wearing parts and components comply with standard requirements and the daily maintenance is convenient.

Margarine&pastry margarine production line is made of the host equipment and auxiliary equipments(Hot Water Tank,batching tank, emulsion tank, aging tank)

| S/N | Name | QTY | Remarks |

| 1 | Quencher | 2 | Heat exchange area : 0.31 x2 = 0.62 m2 Power: 4 kw (quench A), 7.5 kw quench (B) |

| 2 | Malaxator | 1 | frequency conversion stepless speed regulation Volume 27 litres, power: 5.5 kw |

| 3 | Pressure delivery pump | 1 | frequency conversion stepless speed regulation Flow : 2.4 m3/h, power: 4.0 kw |

| 4 | Pressure adjusting valve | 1 | |

| 5 | hand-operated direction valve | 1 | |

| 6 | Hot water circulation tank | 1 | |

| 7 | Refrigeration compressor unit | 1 | Refrigerator : 25 horsepower, R22 (refrigerant) |

| 8 | Electric control box | 1 |

Raw material --->

Batching(batching tank) ---> Emulsifying(Emulsify hot and cold water tank) > pretreated material storage (Hot and cold tank)

--->Precooling of crystallization(Quencher A) ---> Cryogenic crystallization(Quencher B) -> Kneading and refining(Malaxator) --->Outlet of finished product

Structure draft of main machine: