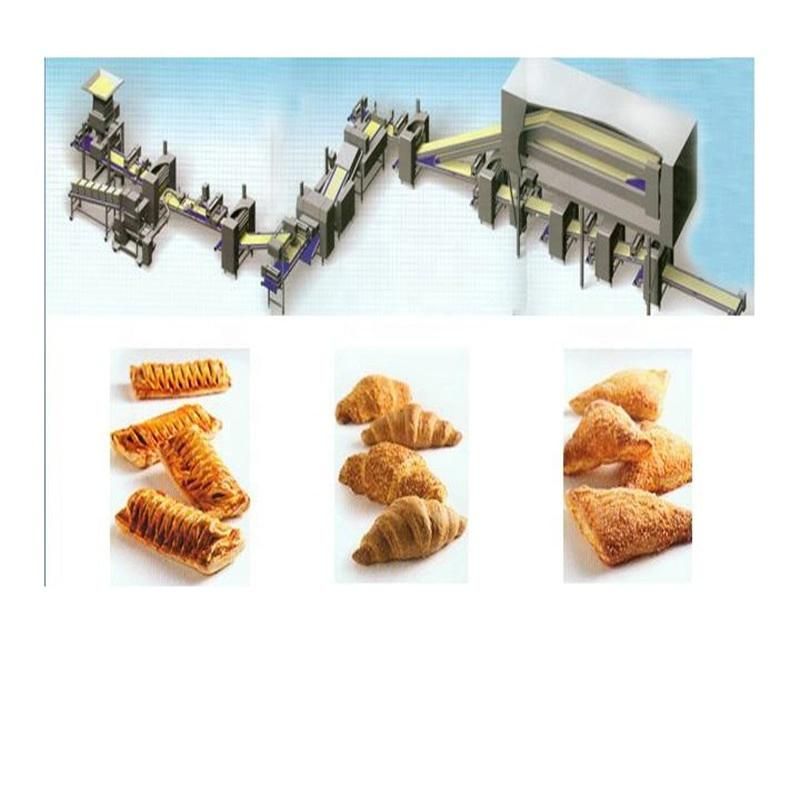

Hot Sale and New Type Automatic Croissant Production Line for Four Rows

Shanghai Target Industry Co., Ltd.- Transport Package:Wooden Package

- Trademark:TGmachine

- Origin:Shanghai

Base Info

- Model NO.:BCro4

- Production Capacity:30sets,Year

Description

No.

Seller

Content

Shanghai Target industry co.,LTD

1

Name of machine

Automatic Croissant production line

2

Capacity

6-8tons/24h

3

Original place

Shanghai, China

4

Type

4 rows

Processing flow:

No.

Machine

Configuration

1

HLY-50

Flour mixer

5 sets

1.including:

a. Stainless steel tank 1 set b. Motor 2 sets

c. Stainless steel stirrer 1 set d. Electrical equipment 1 set

e. safety net cover 1 set f. belt pulley 6pcs

g. B-shape belt 9pcs h. tank 1pc

2. Configuration and parameter

a. Agitator is made of 304-2B

Stainless steel

b. Tank is made of 8-10mm A3

c. Belt pulley is made of cast iron

d. Voltage: 380V 50Hz

e. Power: 5.5kw

f. outside is high temperature baking finish

3. Wearing parts:

a. B type belt

2

Three rollers extruder

1set

1. including:

a. rack and wallboard 1set

b. flour feeding roller 3 sets

c. adjust screw rod 1pc

d. turbine speed changing box 2pcs

e. cover 2pcs

f. motor 2pcs

g. conveyer belt 1pc

h. convey platen 1pc

2. Configuration and parameter

a. Rack is made of 20mm A3

Board

b. Flour feeding roller is

made of accurate grinding 45#

seamless steel tube with

chroming

c. Cover is made of 401 stainless

steel

d. PU conveyer

e. Voltage:380v, 50hz

f. Power: 5kw

3. Wearing parts:

PU conveyer

3

Flour pressing machine

1set

1. including:

a. rack and wallboard 1set

b. flour roller 12pcs

c. big roller 1pc

d. turbine speed changing box 2pcs

e. adjust screw rod 1set

f. conveyer belt 1pc

g. cover 2pcs

h. motor 2pcs

2. Configuration and parameter

a. Rack is made of 20mm A3

Board

b. Flour feeding roller is

made of accurate grinding 45#

seamless steel tube with

chroming

c. Cover is made of 401 stainless

steel

d. PU conveyer

e. Voltage:380v, 50hz

Power: 3kw

Packaging & Shipping

Wooden Packing:

1. Product production is completed, by the quality inspection department to check

2. After inspection qualified, clean for whole machine

3. Packing:

a. Inside the machine put desiccant

b. Add 6 cm thick foam plate around the machine,Then, winding stretch film for reinforcement, and combined with bubble wrap

c. On wood packaging on the outside of the machine, then use metal reinforcement with steel

4. Container: according to different products for reinforcement.

FAQ

Why Choose Us?

- Near 40 years experience in food processing machinery production, established in 1982.

- We are manufacturer and wholesale of dough kneading machine

- We adopt environment-friendly materials and technology

- We mainly sell stock in bulk. OEM orders are welcome

- We can accept the mix order

Our Services

After-Sale Service For Abroad Customers:

1. Free training of machine installation, operation and maintenance will be provided by our engineer.

2. Some spare parts will be sent with the machine for free. It is available to buy the parts from us forever at low price.

3. We will surpport customers after-service forever by call, email and video etc.

4. If necessary, our engineer is available to go to customer's factory for machine installation and adjustment.