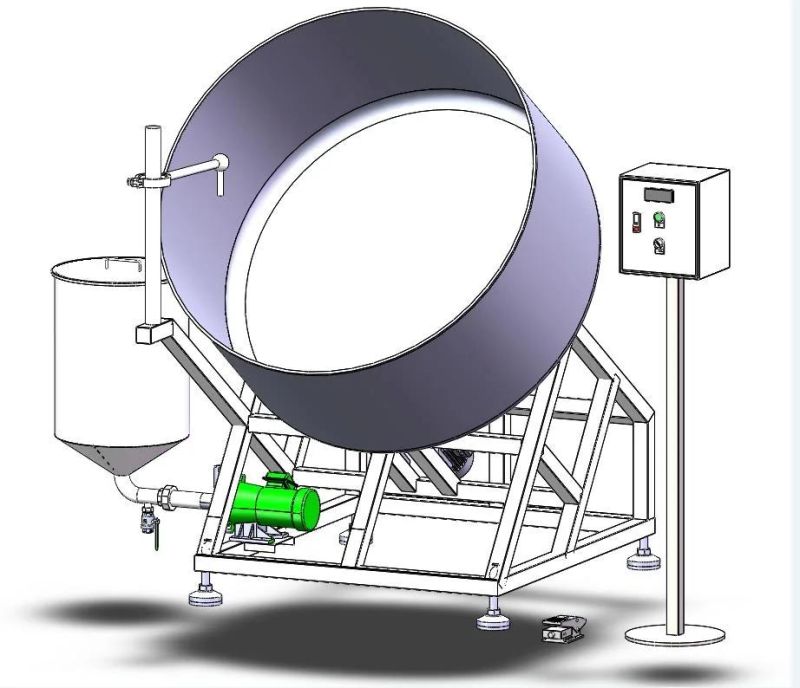

Batch Coated Peanut with Batch Fryer System

Handyware (China) Engineering Co., Ltd.- Certification:ISO9001

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Chips

- Customized:Customized

Base Info

- Transport Package:Wooden Box

- Model NO.:CM1200

- Specification:2.94 x0.8x2.32M

- Trademark:Handyware

- Origin:Foshan

- HS Code:8438800000

- Production Capacity:150-250kg,H

Description

Basic Info.

Model NO. CM1200 Transport Package Wooden Box Specification 2.94 x0.8x2.32M Trademark Handyware Origin Foshan HS Code 8438800000 Production Capacity 150-250kg/HProduct Description

The semi-automatic coating machine,modified from its prototype, is essential for the production of roasted seeds and nuts. It combines needs of different types of customers. This machine can mix products uniformly and render them crispy, it is the first choice for making roasted seeds and nuts.This machine is suitable for continuous operation and is capable of maintaining production load at 10-30kg/batch, 3-6min/batch.

Technical information

| Unit | ||

| Dimensions (W*L*H) | millimeter | 1570 * 1530 * 1900 |

| Throughput scope | Kilogram/batch | 10-30 |

| Suitable for | Nuts, peas, bean, seeds, flour | |

| Compressed air supply | MPA | 0.6-0.8 |

| Power | Kilowatt | Kinematic motor: 0.75 Water pump: 0.75 |

| Liquid container volume | m³ | 0.07 |

| Rated voltage | Volt | 380 |

| Rated frequency | Hertz | 50 |

| Ambient temperature | ºC | 0-40 |

| Ambient pressure | Atmospheric pressure | |

| Weight approximation | Kilogram | 302 |

Customer of Handyware Engineering

Exhibition

Patent Certificate:

Before sale services:

1. Provide initial standard machine configurations.

2.According to the clients' special requirment,offer customized and competitively priced solution. Where necessary,offer customer with options .

3.Help client design the factory and offer professional advice ,provide free drawing for the factory layout.

4.Welcome to visit our factory for machine viewing or trial.

Services during the sales:

1.Provide customer with regular production status update.

2. Invite customer for inspection of machine before delivery.

After sale services:

1.Oversea install of the equipment.

2.Provide the basic food formulation.

3.Operation/Service/Maintenance Manual: Provided in English.

4. We will provide engineers to client's factory for the installation and training . The client is required to provide accomodation,food, round-trip ticket, visa,transportation fee and engineer fee of $80 /day/engineer.

Design of capacity as per needs.