1000L 2000L 3000L 30hl 20bbl Stainless Steel Jacketed Double Layer Heat Preservation ...

Jinan Chenji International Trade Co., Ltd.- After-sales Service:Whole Life

- Warranty:1 Year

- Condition:New

- Customized:Customized

- Voltage:220V

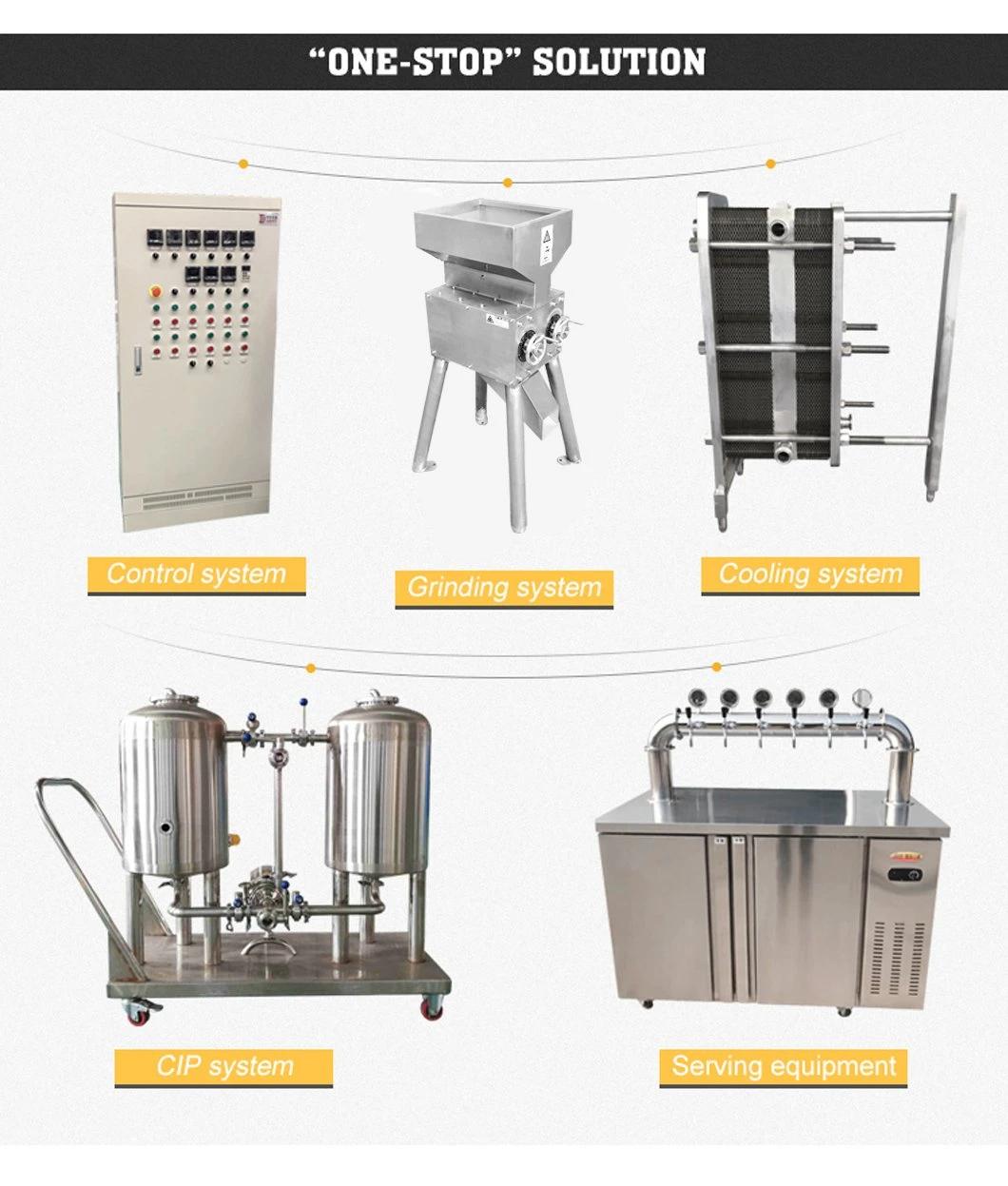

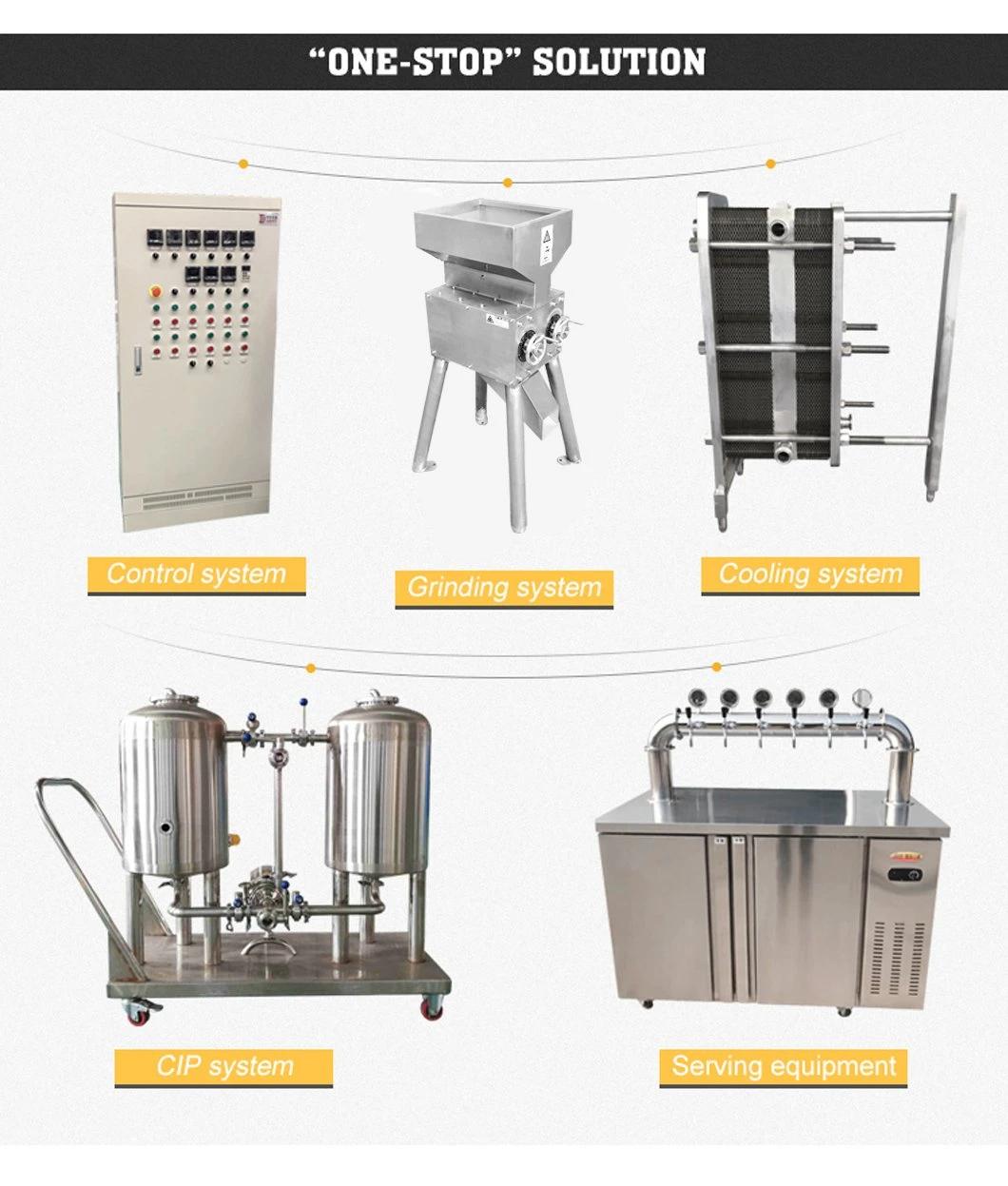

- Composition:CIP Cleaning Machine

Base Info

- Model NO.:CJ-3000

- Processing Material:Barley

- Process:Ferment

- Capacity:2000L 3000L Customzied

- Heating Methods:Steam Jacket

- Legs:3-4 Customzied

- Shellwell:Deep Well Handrail

- Brewhouse:3-4 Vessels

- Fermenting:Beer Wort Ferment Low Temperature

- Spent Grain:Side Manway, Manhole

- Visual Port:Glass Door

- Port Name:Qingdao Shanghai Others

- Stainless Steel 304:2mm 3mm 4mm Thickness

- CIP Washing Ball:Included

- Jacket:Cooling, Heating

- Customzied Drawing:Accept New Idea OEM ODM

- Transport Package:Plywood Case,Container

- Specification:CJ-3000

- Trademark:CJ or OEM

- Origin:China Jinan or Others

- HS Code:8438400000

- Production Capacity:300 Set , Year

Description

SS304 full weldedAlkali Tank Pump adjustable Control System Control Cabinet Semi-automatic

1).-Malting:

First, we hand select the best ingredients from local farmers.

The grain (barley) is soaked and germinated to covert the insoluble starches into sugar that the yeast can turn to alcohol. This "green malt" is then dried at varying temperatures to create the different malt colors and flavors.

If you are the only state brewery to make your own malt using our in-house malting facility. This allows for complete control over the entire process, ensuring the best quality for our distinctive Cascade taste.

2).-Mashing:

Onto the mash tun, here water is added to the malt at just the right temperature to convert the starch from the malt into natural fermentable sugars that the yeast can "eat".

Your water isn't just any water-it comes from special area which lies directly behind the brewery. It is said that this is one of the purest water sources in the world for it comes directly from rain clouds originating in the untouched South.

3).-Lautering:

Lautering is the separation of the sweet malty liquid (called wort) from the grain husks which is collected.

The spent malt from this process is then recycled back into the local farming community for livestock feed, which is very important and necessary for starting new brewing cycle.

4).-Boiling:

The wort is then transferred into a brewing kettle where fresh local hops are added by hand during boiling. It takes an hour or so to concentrate and sterilize the liquid and to allow the many biochemical changes to take place.

The hop alpha acids impart bitterness and the hop oils give the beer characteristic hop aromas. Think of it as "beer seasoning"

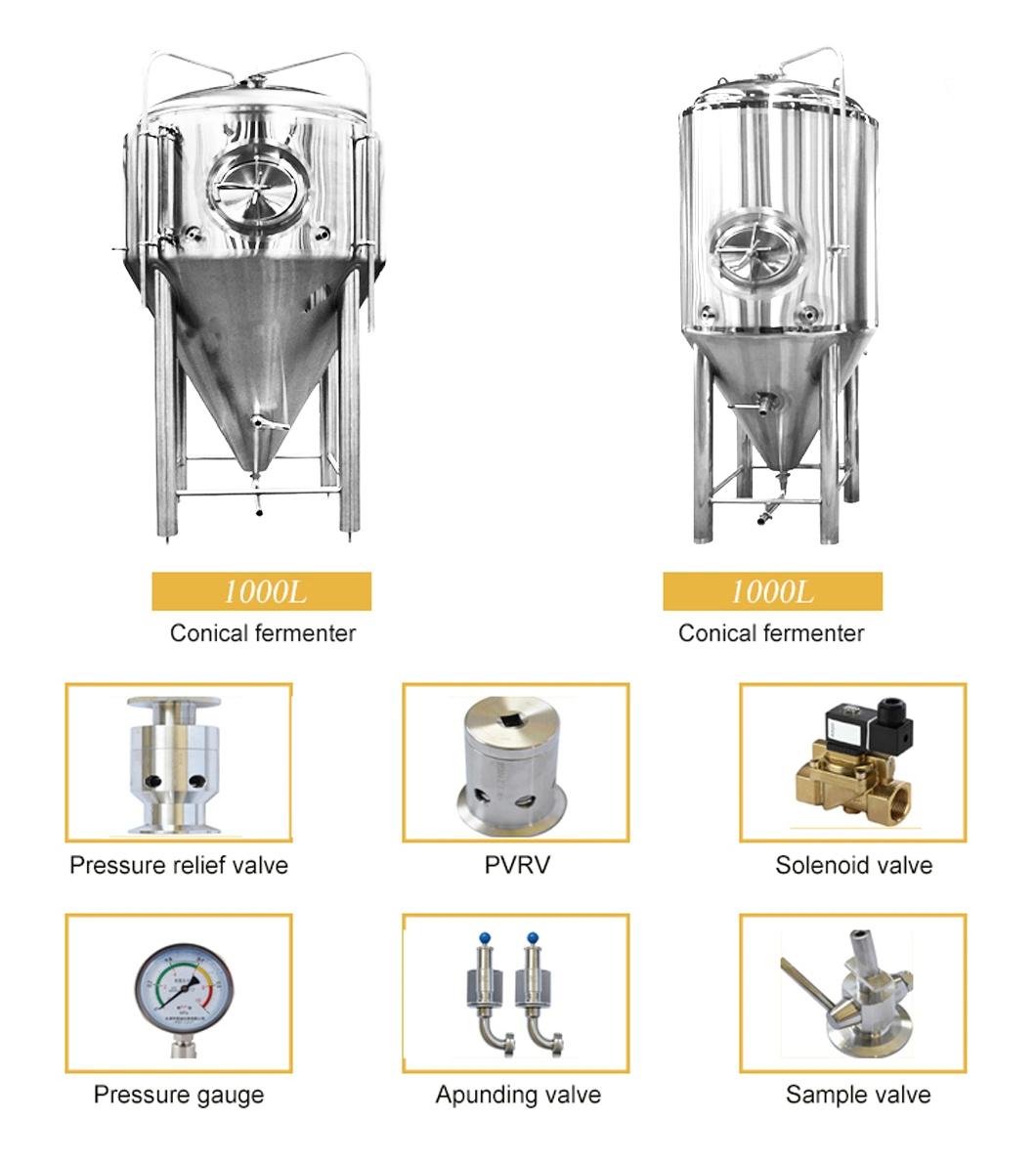

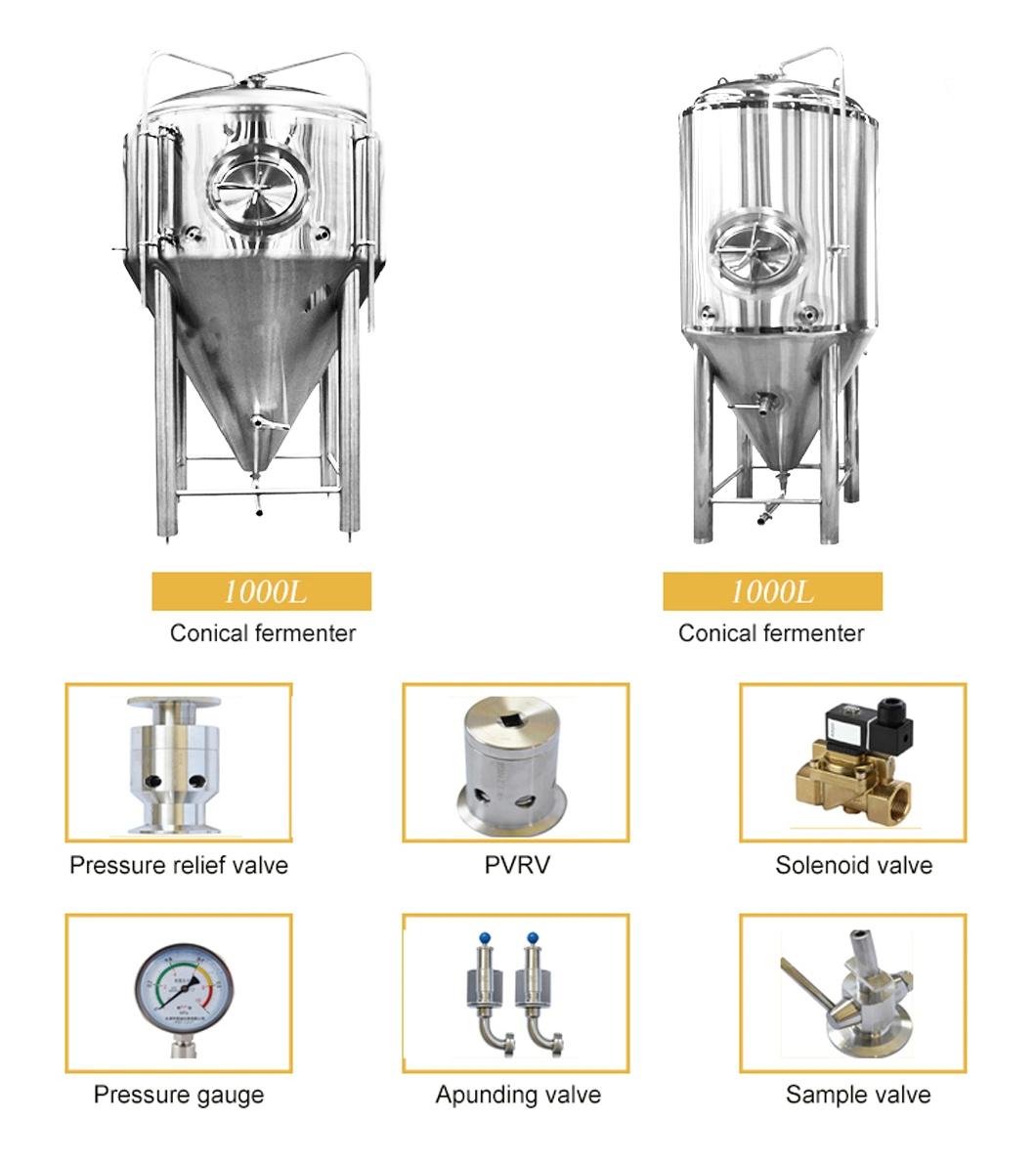

Fermentation tanks:

By now, we have a liquid that has a malt character balanced with bitterness; but a crucial element is still missing: Alcohol. Yeast is the agent of fermentation. Without yeast, there would be no alcohol. And that is why we love our Cascade yeast. Tried, tested and true, this strain has remained unchanged since the 1820's, perfectly suited in our ingredients and brewing style. It's one of our great secrets. Maturation: The "green beer" is stored at cold temperatures to mature. This step is especially important for lager style beers because they are more delicate, needing time for the complex flavors to develop. Now the beer will begin its reaction about 2-3 weeks or much longer.

People can choose how many cone fermentation tanks according to the real product capacity, the cooling medium will by the dimple jacket around. If you have 1000L capacity of the mash lauter tank and boiling kettle, then the fermentation tanks can be 1000L or 2000L. 1:1 or 1:2 ratio is good.

FAQ:

1.Q: Are you professional Supplier and tanks Manufacture ?

A: We are the manufacturer of beer brewing equipment for 15 Year and deal in export business since 10 years ago .

2.Q:Can I have the customized products with personal design?

A:Yes,we support any of your wish design,can design and manufacture as client's requirements.

3.Q: Can you guarantee your beer brewing system quality?

A: All of the equipment will be inspected before the package, appliance of the international Standard.

4.Q:How about the after sales service?

A:For our after-sale service, we promise all life of technical support to all client.

All of our products is available with 10 years warranty even for spare parts within quality warranty period, our service is free of charge.

5.Q: Which export port you use?

A:Commonly we will use Qingdao port, sometime, can be other port as your wish.

6.Q: I am green hand in brewery industry? Could you supply training for us?

A: Yes, our engineer can supply the installation equipment and brewery training service overseas.

7.Q: what is your payment item ?

Our Service

1).-Malting:

First, we hand select the best ingredients from local farmers.

The grain (barley) is soaked and germinated to covert the insoluble starches into sugar that the yeast can turn to alcohol. This "green malt" is then dried at varying temperatures to create the different malt colors and flavors.

If you are the only state brewery to make your own malt using our in-house malting facility. This allows for complete control over the entire process, ensuring the best quality for our distinctive Cascade taste.

2).-Mashing:

Onto the mash tun, here water is added to the malt at just the right temperature to convert the starch from the malt into natural fermentable sugars that the yeast can "eat".

Your water isn't just any water-it comes from special area which lies directly behind the brewery. It is said that this is one of the purest water sources in the world for it comes directly from rain clouds originating in the untouched South.

3).-Lautering:

Lautering is the separation of the sweet malty liquid (called wort) from the grain husks which is collected.

The spent malt from this process is then recycled back into the local farming community for livestock feed, which is very important and necessary for starting new brewing cycle.

4).-Boiling:

The wort is then transferred into a brewing kettle where fresh local hops are added by hand during boiling. It takes an hour or so to concentrate and sterilize the liquid and to allow the many biochemical changes to take place.

The hop alpha acids impart bitterness and the hop oils give the beer characteristic hop aromas. Think of it as "beer seasoning"

Fermentation tanks:

By now, we have a liquid that has a malt character balanced with bitterness; but a crucial element is still missing: Alcohol. Yeast is the agent of fermentation. Without yeast, there would be no alcohol. And that is why we love our Cascade yeast. Tried, tested and true, this strain has remained unchanged since the 1820's, perfectly suited in our ingredients and brewing style. It's one of our great secrets. Maturation: The "green beer" is stored at cold temperatures to mature. This step is especially important for lager style beers because they are more delicate, needing time for the complex flavors to develop. Now the beer will begin its reaction about 2-3 weeks or much longer.

People can choose how many cone fermentation tanks according to the real product capacity, the cooling medium will by the dimple jacket around. If you have 1000L capacity of the mash lauter tank and boiling kettle, then the fermentation tanks can be 1000L or 2000L. 1:1 or 1:2 ratio is good.

FAQ:

1.Q: Are you professional Supplier and tanks Manufacture ?

A: We are the manufacturer of beer brewing equipment for 15 Year and deal in export business since 10 years ago .

2.Q:Can I have the customized products with personal design?

A:Yes,we support any of your wish design,can design and manufacture as client's requirements.

3.Q: Can you guarantee your beer brewing system quality?

A: All of the equipment will be inspected before the package, appliance of the international Standard.

4.Q:How about the after sales service?

A:For our after-sale service, we promise all life of technical support to all client.

All of our products is available with 10 years warranty even for spare parts within quality warranty period, our service is free of charge.

5.Q: Which export port you use?

A:Commonly we will use Qingdao port, sometime, can be other port as your wish.

6.Q: I am green hand in brewery industry? Could you supply training for us?

A: Yes, our engineer can supply the installation equipment and brewery training service overseas.

7.Q: what is your payment item ?

Our Service

- Customized according to your personal request based on our standard configuration

- After Sale Service for whole life if you have request

- 24hours on line, supply solutions any time

- 3 Years Warranty for the Main Equipment

- Spares parts replacement and repair service

- Engineer goes to your city for installation, debugging and brewing training if you need

- Provide the import documents that you need for customs clearance and reduce Tax.

- Supply the latest news for the brewing industry and brewing technology

- Port to Port, Door to Door service