Specialized Manufacturer Industrial Assembly Line Inspection Belt Conveyor Automated Type

Zhengzhou Syoung Machinery Co., Ltd.- After-sales Service:Long Time Service

- Warranty:1 Year

- Processing Material:Animal Raw Materials, Forest Products, Special Agricultural Products, Garden Products, Agronomic Products, Natural Ingredients

- Application:Pet Food, Chocolate, Ice Cream, Vegetable, Fruit, Dairy, Beverage

- Customized:Customized

- Power Source:Electric

Base Info

- Model NO.:SYBT Belt Conveyor

- Automatic Grade:Automatic

- Belt Material:PVC,PU,Rubber

- Frame Material:SUS304,Carbon Steel

- Parameter:Customized

- Usage:Conveying

- Loading Capacity:5-500kg

- Conveyor Length:Customized

- Conveyor Width:300,400,500,600,700,800,1000,1200mm

- Conveyor Hight:Customized

- Driven:Electric Motor

- Speed:Fixed,Variable

- Belt Color:White,Blue,Black,Green

- Caster:Fixed,Movable

- Strength of Extension:Strong

- Date of Delivery:Within 10-20 Working Days

- Transport Package:Plywood Case

- Specification:Customized

- Trademark:No Brand

- Origin:China

- Production Capacity:2000pieces,Year

Description

Basic Info.

Model NO. SYBT Belt Conveyor Automatic Grade Automatic Belt Material PVC/PU/Rubber Frame Material SUS304/Carbon Steel Parameter Customized Usage Conveying Loading Capacity 5-500kg Conveyor Length Customized Conveyor Width 300/400/500/600/700/800/1000/1200mm Conveyor Hight Customized Driven Electric Motor Speed Fixed/Variable Belt Color White/Blue/Black/Green Caster Fixed/Movable Strength of Extension Strong Date of Delivery Within 10-20 Working Days Transport Package Plywood Case Specification Customized Trademark No Brand Origin China Production Capacity 2000pieces/YearProduct Description

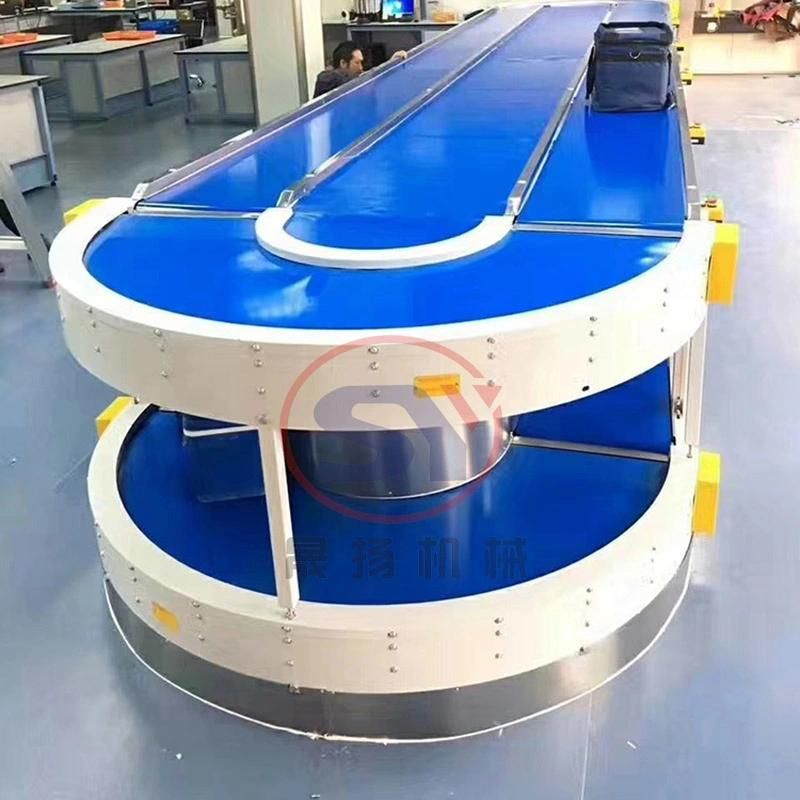

Specialized Manufacturer Industrial Assembly Line Inspection Belt Conveyor Automated TypeIntroduction

Belt conveyors are used to convey heavy and light goods, it can convey all kinds of bulk material, also can convey various cargoes in packages such as cartons, packaging bags, plastic cases which are not heavy duty, thus belt conveyors are very common in food, electric, chemical and printing industries.

Application

| Powder/Granular Products Convey | Grain, cereal, muesli, plastic particle, coffee beans, coffee powder, wheat powder etc. |

| Finish Products Convey | Potato chips, bread, sandwich, burger, small food, ham, bacon, snack puffed food etc. |

| Fruit Vegetable Sort&Inspect | Apple, orange, date, palm, tomato, potato, garlic, carrot etc. |

| Logistic & Transportation | Cartons, bags, box, tray, pallet, barrel, bottles, cans, jars etc. |

| Factory Processing Line | Toys, electric elements, hardware tools, pharmacy, chemical, food industries etc. |

Belt Conveyor Classification 1. Linear belt conveyor; 2. Inclined belt conveyor;3. Turning belt conveyor(45degree, 90 degree, 180 degree).

Technical Parameters

Technical Parameters| 1 | Belt Width | 400mm, 500mm, 600mm, 650mm, 800mm, 1000mm, 120mm, 1500mm etc. |

| 2 | Length | Customized according to customers' need |

| 3 | Height | Customized according to customers' need |

| 4 | Belt Material | Rubber, PVC, PU etc. Food grade belt is available. |

| 5 | Frame Material | Carbon steel, Stainless steel, Aluminum. |

| 6 | Driving Device | Electric motor or electric drum |

| 7 | Transmission Device | Chain |

| 8 | Conveying Speed | Fixed speed or variable speed. |

Optional Accessories of Belt Conveyor 1. Easy to move caster or adjustable feet; 2. Guardrail to prevent items from falling;3. Worktables and lamp brackets can be added according to customers' needs.

Product Pictures

Production Process

Packaging & Shipping

1. Generally packed in Plywood case;

2. Shipment within 10~20 working days after the advance/full payment.

All these conveyors are customized according to customers' requirements, please kindly state your specific needs such as length and width of conveyor when send inquiries, thanks.

About Us

Zhengzhou Syoung Machinery Co., Ltd. is specialized in manufacturing and exporting transmission conveyors and equipment for decades.

All kinds of conveyors such as roller conveyor, belt conveyor, chain conveyor, wire mesh conveyor, screw conveyor, flexible conveyors are supplied to satisfy your different transmission demands.

We have professional technical engineer team, who have more than 20 years experience in transmission conveyor solutions for different fields.

Be your best and professional transmission solution partner is our pursue.

Our Service

1. Project Design

Offer best transmission conveyor solutions according to customers' demands.

2. Response within 24hour

Inquiries, questions and messages from customers will be responded within 24 hours.

3. Installation Training

Provide all-sided equipment installation guidance include but not limited to offer installation instructions, telephone guidance, help to train customers' workers through video session or site instruction.

4. After-sale service

24 hours online for technical consulting service, one year warranty, life-long maintenance; long-term technical support.

If you are interested in this product, please feel free to contact Ms. Sharon, Thanks.